Design and Implementation of HC900 Control System - HC900 Control System Operational Modes

46 HC900 Process & Safety Controller Safety Manual Revision 1.9

01/14

HC900 Control System Operational Modes

Refer installation guide information on operating modes.

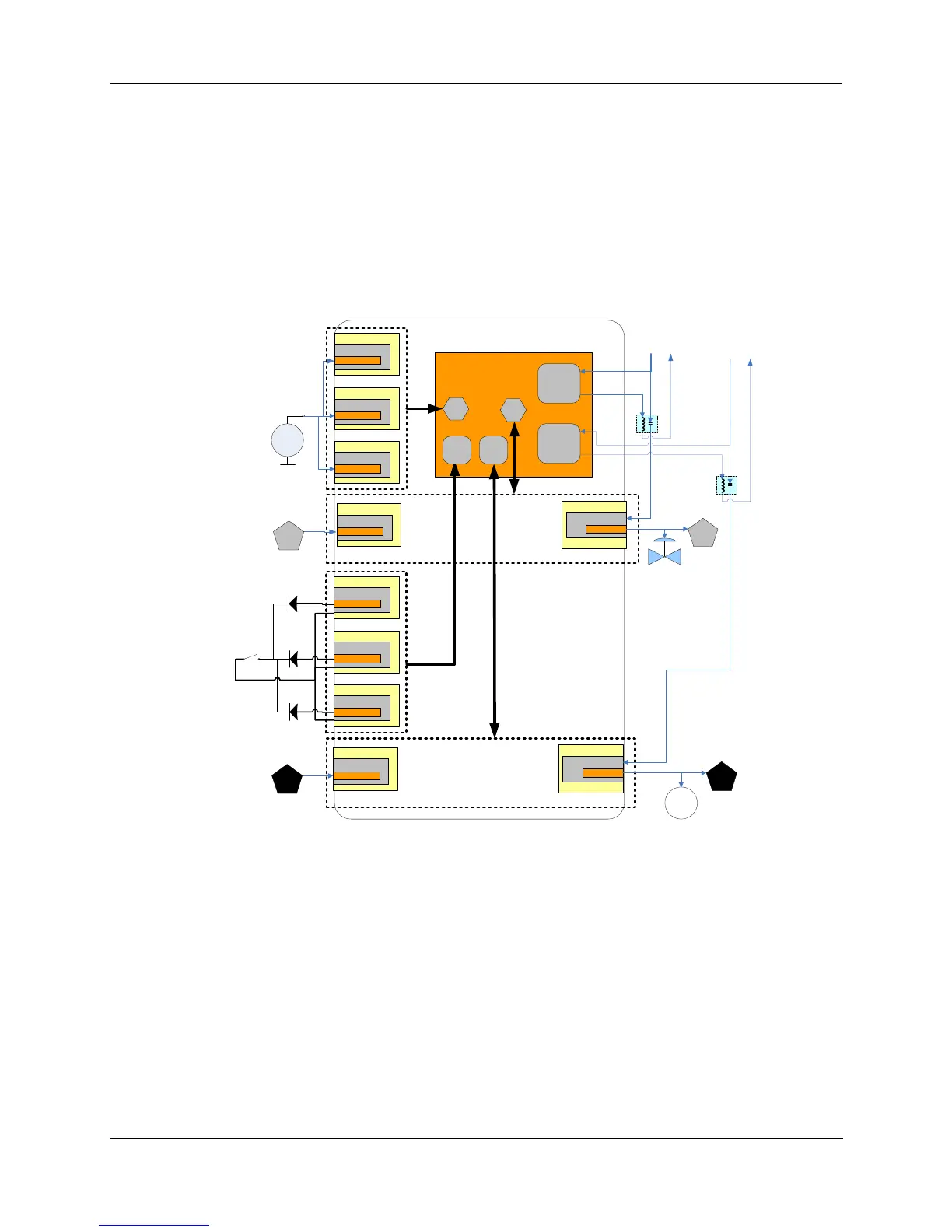

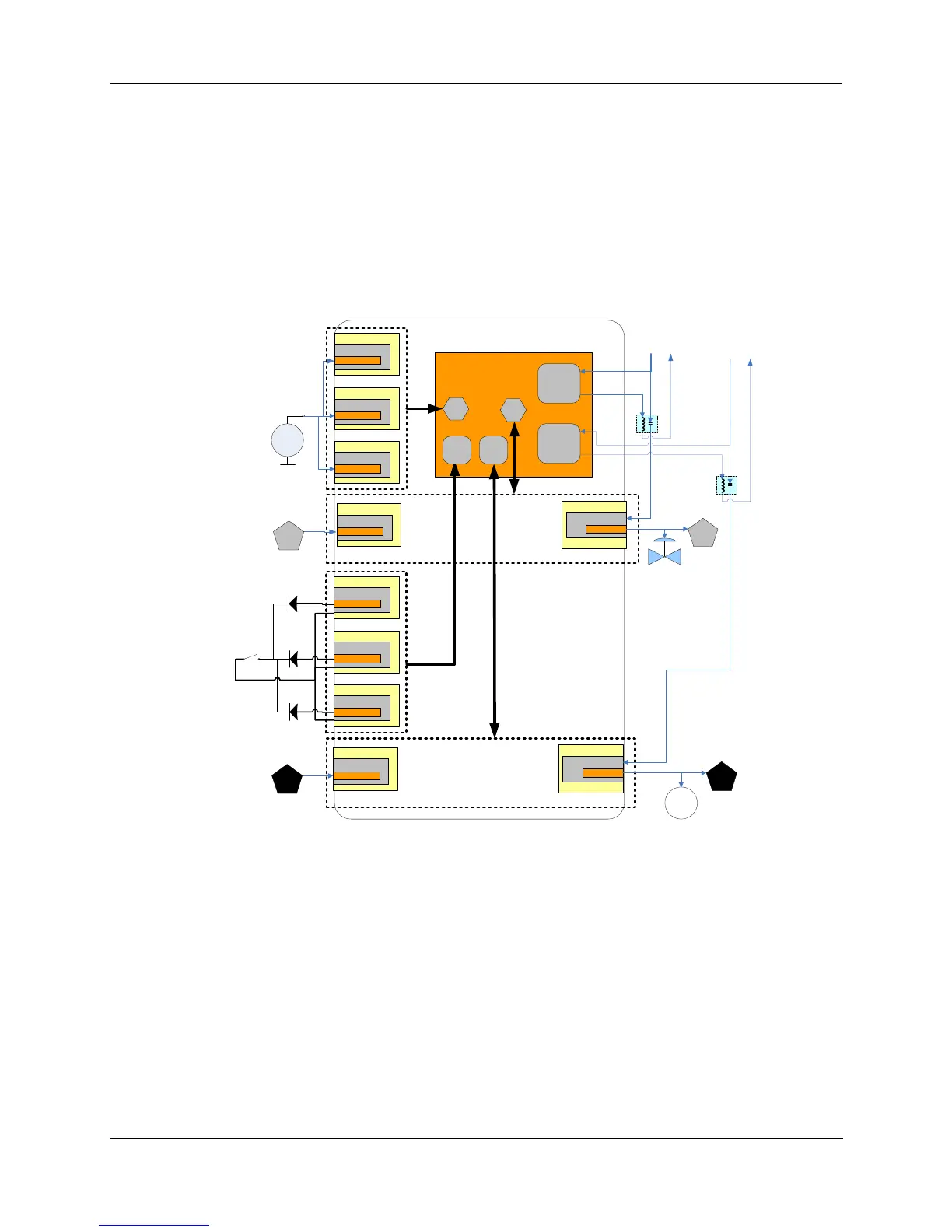

Hardware and wiring requirements for safety configuration

The IO channels used in a safety configuration require approved listed IO modules and interconnected to

ensure proper fault detection and action is achieved. The diagram below outlines this wiring concept.

xx

yyy

Rack ‘1’

AI Module

Channel ‘z'

Rack ‘2’

AI Module

Channel ‘z'

Rack ‘3’

AI Module

Channel ‘z'

Rack ‘1’

AO Module

Channel ‘z'

Rack ‘1’

AI Module

Channel ‘z'

Rack ‘1’

DI Module

Channel ‘z'

Rack ‘2’

DI Module

Channel ‘z'

Rack ‘3’

DI Module

Channel ‘z'

Rack ‘1’

DO Module

Channel ‘z'

Rack ‘1’

DI Module

Channel ‘z'

Users Safety Worksheet configuration

DI-V DO-V

M

*

*

*

Master

Field power

Digital N.O.

Contact

Field Power

AI-V

AO-V

Master

Field power

Digital N.O.

Contact

Field Power

A

A

B

B

External Master

Field Relay

* External diodes are

required on contact

inputs (900G01-xxxx)

External Master

Field Relay

Figure 12 – IO-V function block connections

The external master field relay shown in Figure 12 is further demonstrated in Figure 13 through Figure 15.

They demonstrate the connection of the series output relay’s NORMALLY OPEN contact to protect

against outputs that are stuck “ON”. This relay may be added individually as shown in Figure 13 and

Figure 15 or common for multiple channel outputs as shown in Figure 14 and Figure 15. The external

master field relay must be configured to open when the DO-V or AO-V functions on the safety worksheet

indicate a failure with the Fail or VFail pin “ON”.

Loading...

Loading...