Do you have a question about the Honeywell UMC800 and is the answer not in the manual?

Provides descriptions and procedures for installation, operation and maintenance of the UMC800 Controller hardware.

Lists documents that may be sources of reference for material discussed in this publication.

Lists Honeywell's World Wide Web sites and telephone numbers for customer support.

Explains the scope and organization of the installation and user guide for the UMC800 Controller.

Details the UMC800 as a modular controller designed for small unit process control.

Lists key features of the UMC800 controller, including control loops, I/O capacity, and options.

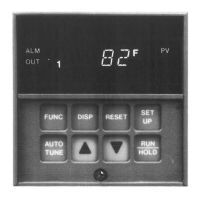

Describes the main parts housed within the UMC800 controller enclosure.

Explains the function block configuration architecture for developing control strategies.

Introduces pre-installation checks and environmental factors for controller installation.

Lists recommended operating limits for the controller's environment and power.

Details site requirements for mounting the controller enclosure and external wiring.

Lists tools and parts required for mounting the UMC800 hardware.

Details the steps for surface mounting the controller enclosure onto a panel.

Describes the backplane's role in connecting modules and the slot numbering.

Explains how to identify I/O module types using labels and terminal blocks.

Details how to connect field wiring to the controller's I/O module terminal blocks.

Explains remote access capabilities, including monitoring, configuration, and firmware upgrades.

Lists the essential capabilities a modem must have for remote access.

Specifies the interface cable needed to connect a modem to the controller.

Explains the controller's power-up sequence, diagnostics, and power-down behavior.

Defines PROGRAM, RUN, and OFFLINE modes and their uses.

Explains how the controller's operational mode can be set and changed.

Explains how to upgrade the controller's firmware using the User Utility software.

Explains how scan rates are determined by the number of analog inputs and function blocks.

Details the meaning of the POWER, LoBAT, FORCE, and RUN status LEDs on the CPU module.

Describes the COMM A and COMM B ports and their setup for communication.

Explains how to check the status of COMM A and COMM B ports.

Outlines the scope of maintenance procedures for the controller and its components.

Details warranty repair services for the controller.

Discusses easy removal of components and battery access for maintenance.

Recommends periodic physical inspection of the controller enclosure and wiring.

Provides guidance on replacing the CPU battery.

Describes accessing calibration displays via operator interface or user utility.

Outlines how to initiate calibration routines via operator interface or user utility.

Describes calibrating AI module channels using 0% and 100% reference values.

Introduces diagnostic routines and indicators for controller operating status.

Explains diagnostic routines executed during power-up and continuous operation.

Describes the internal diagnostics performed upon controller power application.

Mentions diagnostic displays for controller status and I/O module diagnostics.

Introduces the tables containing electrical, physical, safety, and performance specifications.

Describes the overall design and capabilities of the UMC800 controller.

Explains how scan rates vary based on the number of analog inputs and function blocks.

Details the standard and optional power supply voltage ranges and fuses.

Details the controller's communication ports, protocols, and connection parameters.

| Model | UMC800 |

|---|---|

| Mounting | Panel Mount |

| Type | Controller |

| Controller Type | Digital |

| Input Voltage | 100 to 240 VAC |

| Outputs | Analog Outputs, Digital Outputs |

| Communication Protocols | Modbus RTU, Ethernet |

| Display | LCD |

| Power Supply | 100-240V AC, 24V DC |