Model 4342A

3-10. MEASUREMENT TERMINALS.

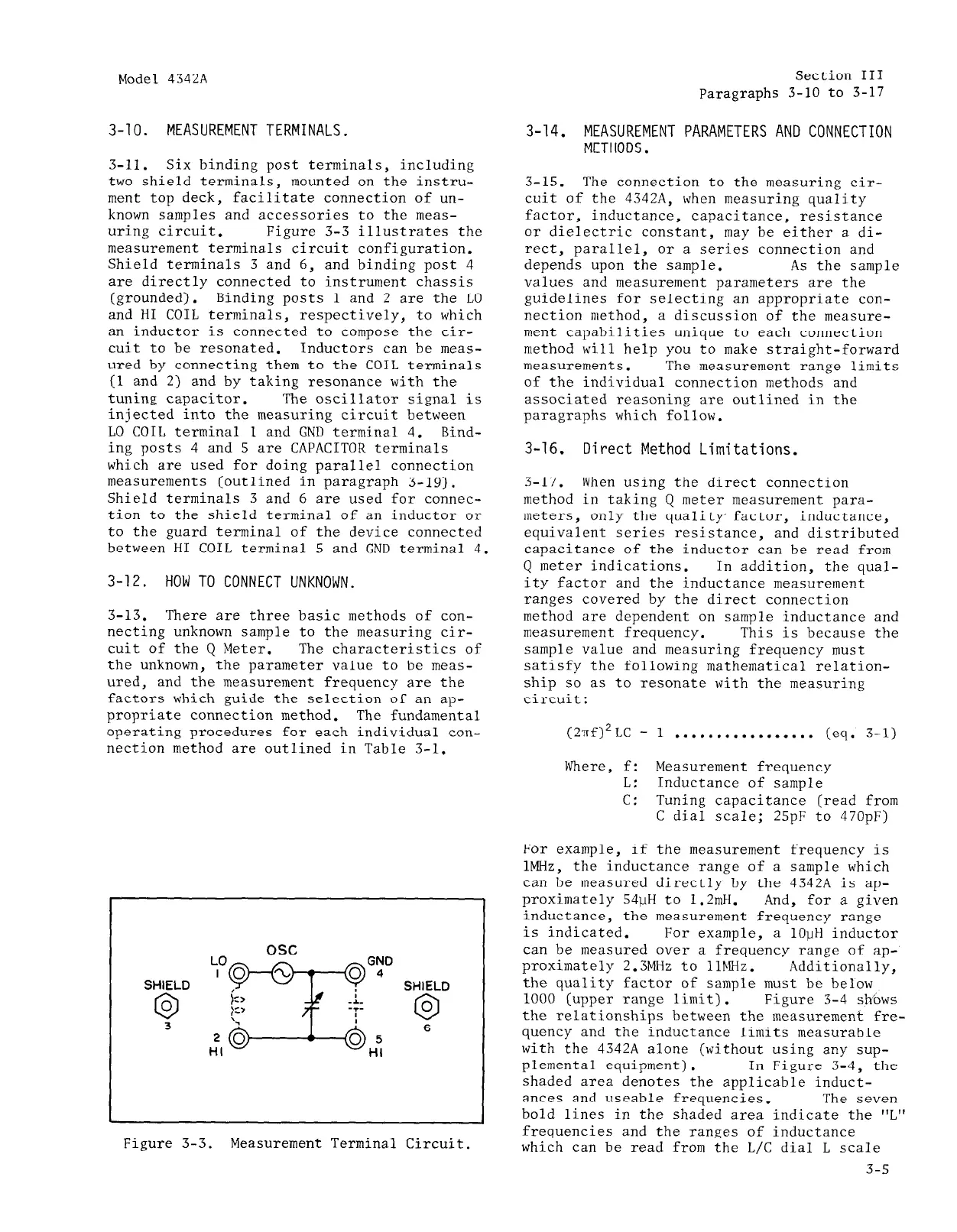

3-11. Six binding post terminals, including

two shield terminals, mounted on the instru-

ment top deck, facilitate connection of un-

known samples and accessories to the meas-

uring circuit. Figure 3-3 illustrates the

measurement terminals circuit configuration.

Shield terminals 3 and 6, and binding post 4

are directly connected to instrument chassis

(grounded). Binding posts 1 and 2 are the LO

and HI COIL terminals, respectively, to which

an inductor is connected to compose the cir-

cuit to be resonated. Inductors can be meas-

ured by connecting them to the COIL terminals

(1 and 2) and by taking resonance with the

tuning capacitor.

The oscillator signal is

injected into the measuring circuit between

LO COIL terminal 1 and GND terminal 4. Bind-

ing posts 4 and 5 are CAPACITOR terminals

which are used for doing parallel connection

measurements (outlined in paragraph 3-19).

Shield terminals 3 and 6 are used for connec-

tion to the shield terminal of an inductor or

to the guard terminal of the device connected

between HI COIL terminal 5 and GND terminal 4.

3-12. HOW TO CONNECT UNKNOWN.

3-13. There are three basic methods of con-

necting unknown sample to the measuring cir-

cuit of the Q Meter. The characteristics of

the unknown, the parameter value to be meas-

ured, and the measurement frequency are the

factors which guide the selection of an ap-

propriate connection method. The fundamental

operating procedures for each individual con-

nection method are outlined in Table 3-l.

SHIELD

0

0

3

SHIELD

0

0

6

Figure 3-3.

Measurement Terminal Circuit.

Section III

Paragraphs 3-10 to 3-17

3-14. MEASUREMENT PARAMETERS AND CONNECTION

METHODS.

3-15. The connection to the measuring cir-

cuit of the 4342A, when measuring quality

factor, inductance, capacitance, resistance

or dielectric constant, may be either a di-

rect, parallel, or a series connection and

depends upon the sample. As the sample

values and measurement parameters are the

guidelines for selecting an appropriate con-

nection method, a discussion of the measure-

ment capabilities unique to each connection

method will help you to make straight-forward

measurements. The measurement range limits

of the individual connection methods and

associated reasoning are outlined in the

paragraphs which follow.

3-16.

Direct Method Limitations.

3-17.

When using the direct connection

method in taking Q meter measurement para-

meters, only the quality' factor, inductance,

equivalent series resistance, and distributed

capacitance of the inductor can be read from

Q meter indications. In addition, the qual-

ity factor and the inductance measurement

ranges covered by the direct connection

method are dependent on sample inductance and

measurement frequency. This is because the

sample value and measuring frequency must

satisfy the following mathematical relation-

ship so as to resonate with the measuring

circuit:

(2Trf)2LC = 1 . . . . . . . . . . . . . . . . . (eq. 3-l)

Where, f: Measurement frequency

L: Inductance of sample

c:

Tuning capacitance (read from

C dial scale; 25pF to 470pF)

For example, if the measurement frequency is

lMHz, the inductance range of a sample which

can be measured directly by the 4342A is ap-

proximately 54uH to 1.2mH. And, for a given

inductance, the measurement frequency range

is indicated. For example, a 1OuH inductor

can be measured over a frequency range of ap-

proximately 2.3MHz to 11MHz. Additionally,

the quality factor of sample must be below

1000 (upper range limit). Figure 3-4 sh/ows

the relationships between the measurement fre-

quency and the inductance limits measurable

with the 4342A alone (without using any sup-

plemental equipment). In Figure 3-4, the

shaded area denotes the applicable induct-

ances and useable frequencies. The seven

bold lines in the shaded area indicate the "L"

frequencies and the ranges of inductance

which can be read from the L/C dial L scale

3-5

Loading...

Loading...