Model 4342A

Parallel Connection Measurements

Section III

Paragraphs 3-71 and 3-72

3-71. Dielectric Measurement.

3-72. The dielectric constant and dielectric

loss of insulating materials can be measured

by a method similar to and is basically a

capacitance measurement.

When a pair of

parallel electrodes (air capacitor) connected

to 4342A (in air) and an insulating material

placed between the electrodes, the electrode

capacitance increases in proportional to the

specific inductive capacity (ES) of the

sample material.

The dielectric constant of

the sample material is calculated as the pro-

duct of Es and the vacuum dielectric constant

CO.

Accordingly, the dielectric constant can

be determined from the capacitance measure-

ments made before and after placing the

sample between the elecrodes.

Additionally,

after the sample is mounted in the holder,

the conductance of the sample can also be

calculated from a reduction of the Q meter

indication. To make easy and accurate

dielectric measurements, it is recommended

that the 16451A Dielectric Test Adapter be

used with the 4342A.

Typical characteristics

of the 16451A are described in Table 3-2.

Materials to be measured with the 16451A

should be less than 1Omm in thickness and

from 38 to 55nn in diameter.

When measuring

materials with a high dielectric constant or

a large loss, it is usually best to prepare

material in thicknesses greater than 3nn.

On the other hand, when low loss material is

to be measured, the material thickness should

be less than 3mm.

Materials measuring less

than 0.5mm in thickness are usually difficult

to measure.

To make dielectric measurements using the

16451A, proceed as follows:

a.

b.

CO

d.

e.

f.

Depress the appropriate FREQUENCY

RANGE button and set FREQUENCY dial

control for the desired measurement

frequency.

Select a reference inductor which can

resonate at the measurement frequency.

Connect it to 4342A measurement COIL

(HI and LO) terminals.

Adjust L/C dial and AC dial controls

for a maximum Q meter deflection.

Note sum of the C dial and AC dial

readings as Cl and panel meter read-

ing as Qi.

Let the reference inductor remain in

place (as is) and attach the 16451A to

4342A measurement CAPACITOR (HI and

GND) terminals.

Set 16451A electrode spacing as de-

sired.

However, if possible, it is

best to set the electrode spacing

dimension to about the same as the

thickness of the material to be

measured.

Again resonate the measurement circuit

by adjusting the L/C and AC dial con-

trols.

Note C dial and AC dial read-

ings as C2 and panel meter reading Qa.

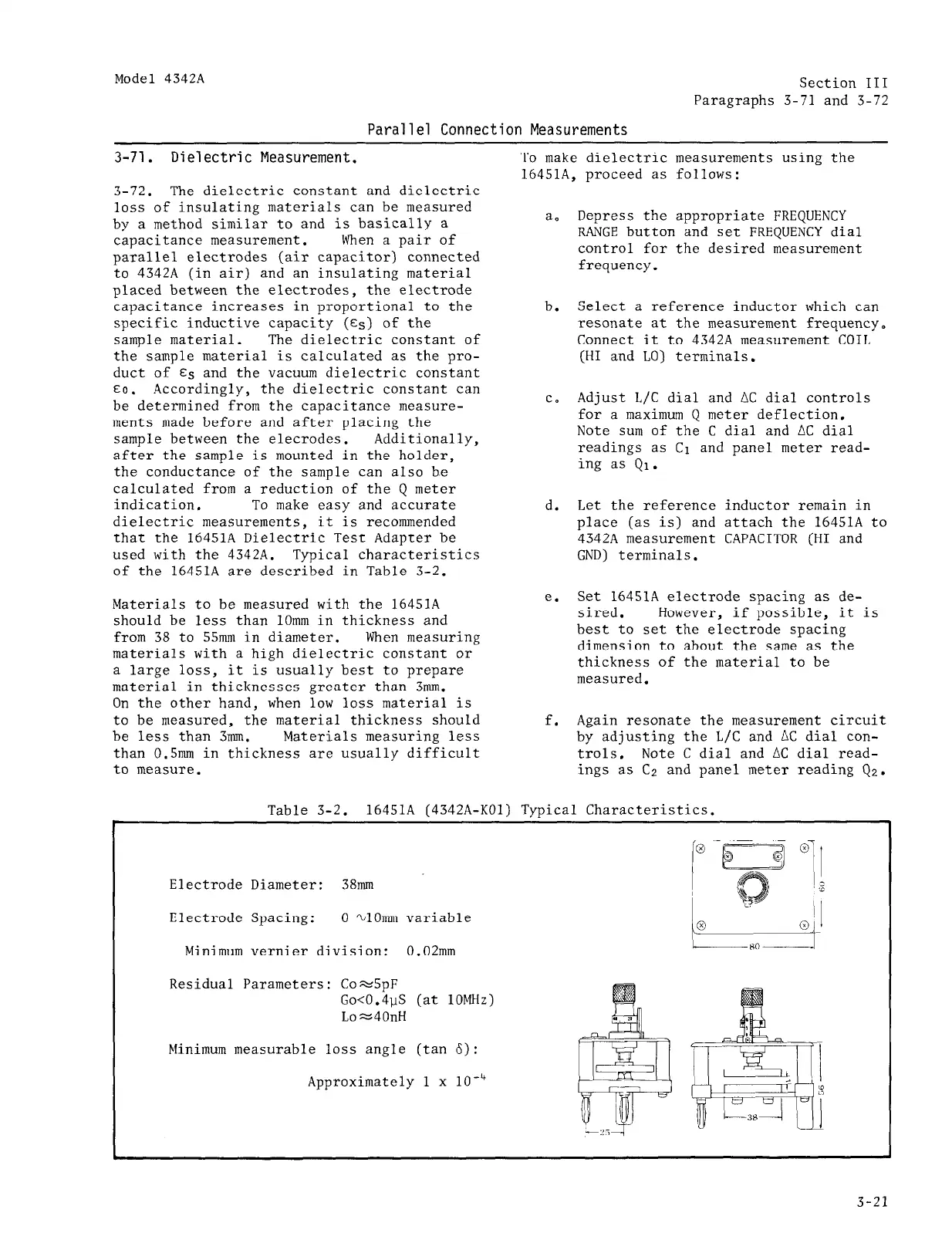

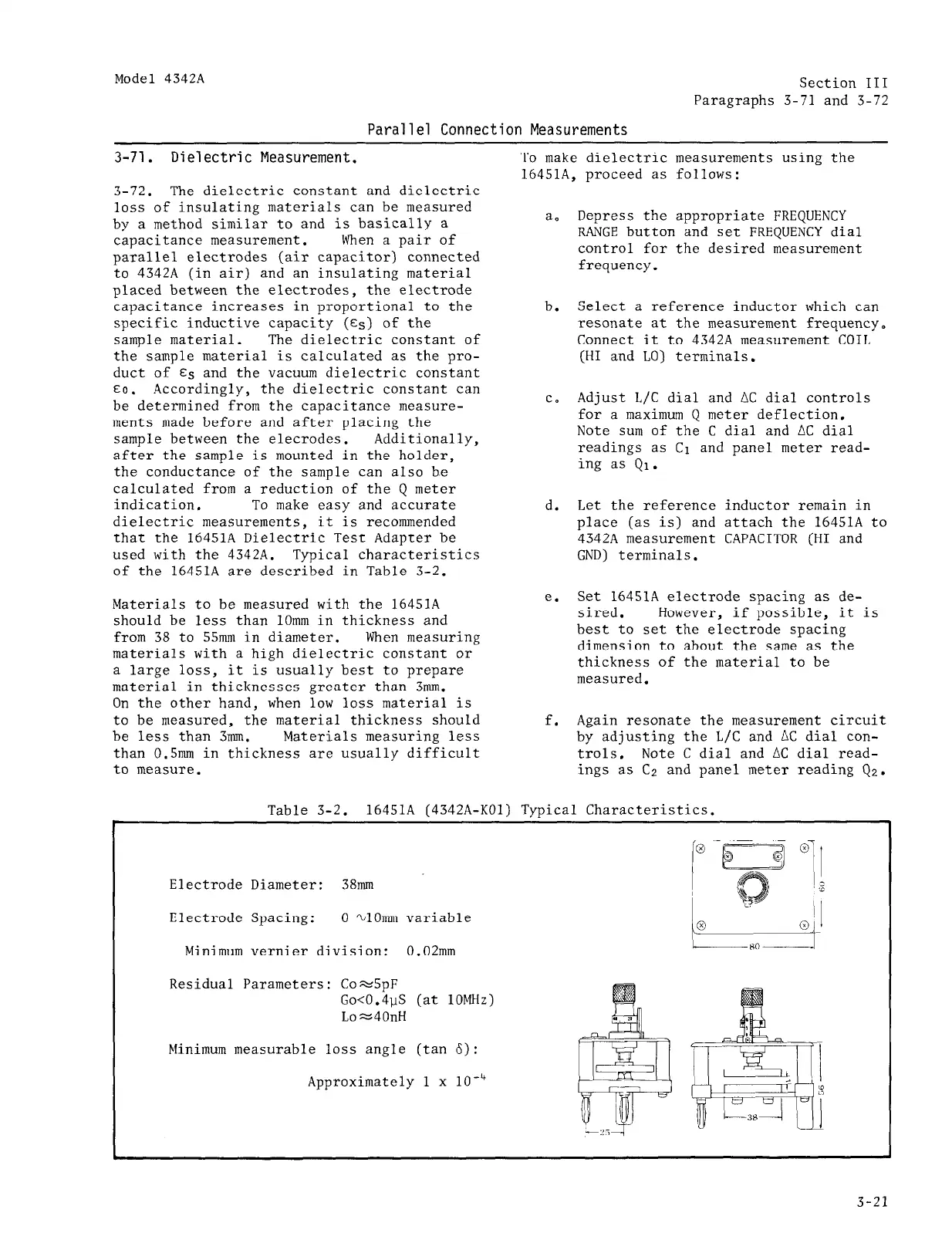

Table 3-2.

16451A (4342A-KOl) Typical Characteristics.

Electrode Diameter: 38mm

Electrode Spacing: 0 ~1Omm variable

Minimum vernier division: 0.02nm

Residual Parameters: Co=5pF

Go<0.4uS (at 1OMHz)

Loz40nH

Minimum measurable loss angle (tan 6):

Approximately 1 x 10e4

3-21

Loading...

Loading...