LP-387 Rev. 011 Rel. 005 Date 1.3.19

37

NOTE: Check with your local gas company to determine if

combustion condensate disposal is permitted in your area. In the

state of Massachusetts, condensate must be neutralized before

entering a drain.

This boiler is a high eciency appliance, and therefore produces

condensate: a by-product of the combustion process. A condensate

collection system with an internal oat switch monitors condensate

level to prevent it from backing up into the combustion system.

There is a exible line that must be piped to a drain or condensate

pump.

Condensate from the boiler is slightly acidic with a pH of 3.2 - 4.5. To

avoid long term damage to the drainage system and to meet local

code requirements, HTP recommends neutralizing condensate with

a Condensate Neutralizer Kit (Part # 7450P-212 for 55 - 285 models,

Part # 7350P-611 for the 399 model). The neutralizer kit connects to

the drain system and contains limestone chips that neutralize the

pH level of the condensate. The neutralizer kit should be checked

annually and the limestone chips replenished if necessary. When

replacing the limestone chips, take care to ensure chips are no

smaller than ½” to avoid blockage in condensate piping (refer to

Figure 26 for piping of the condensate neutralizer.)

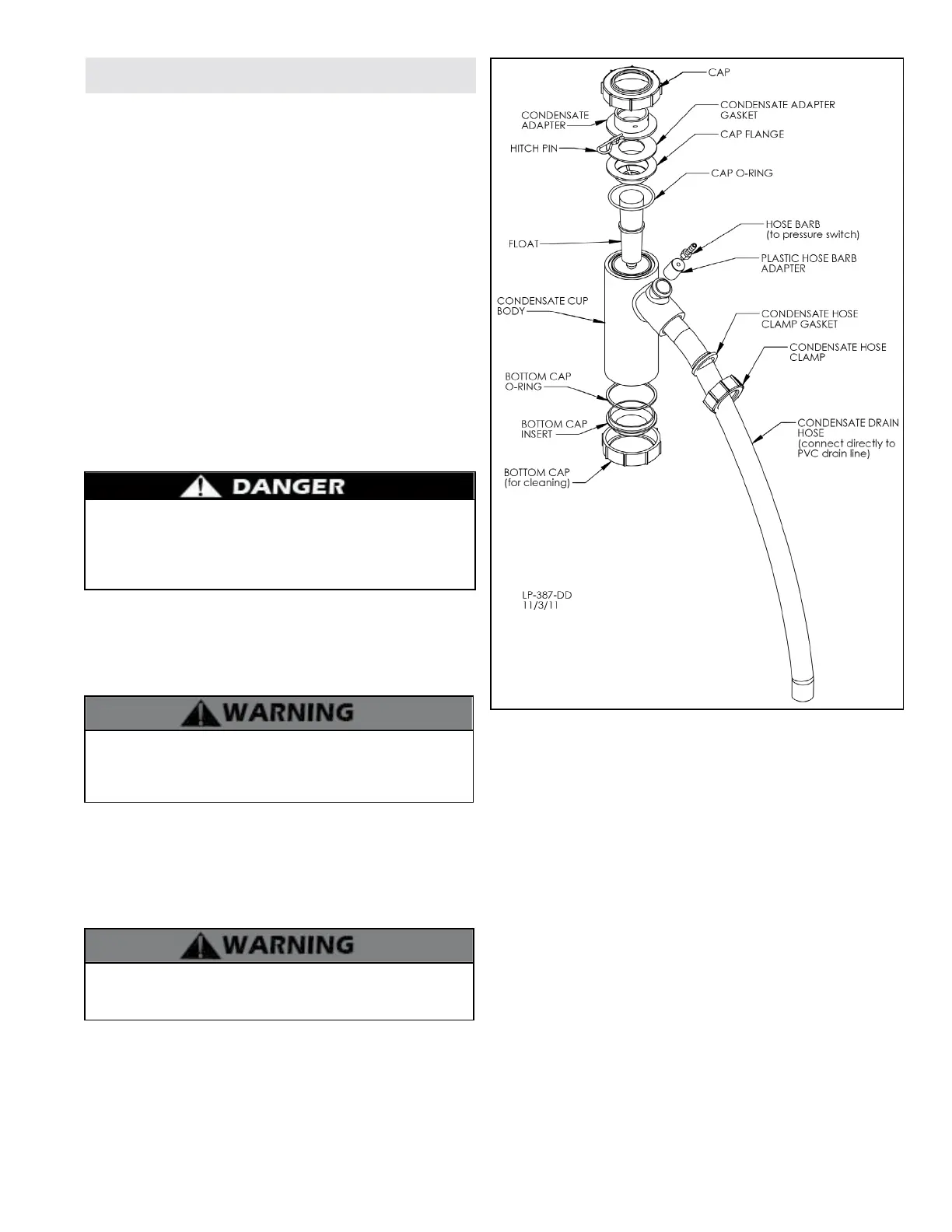

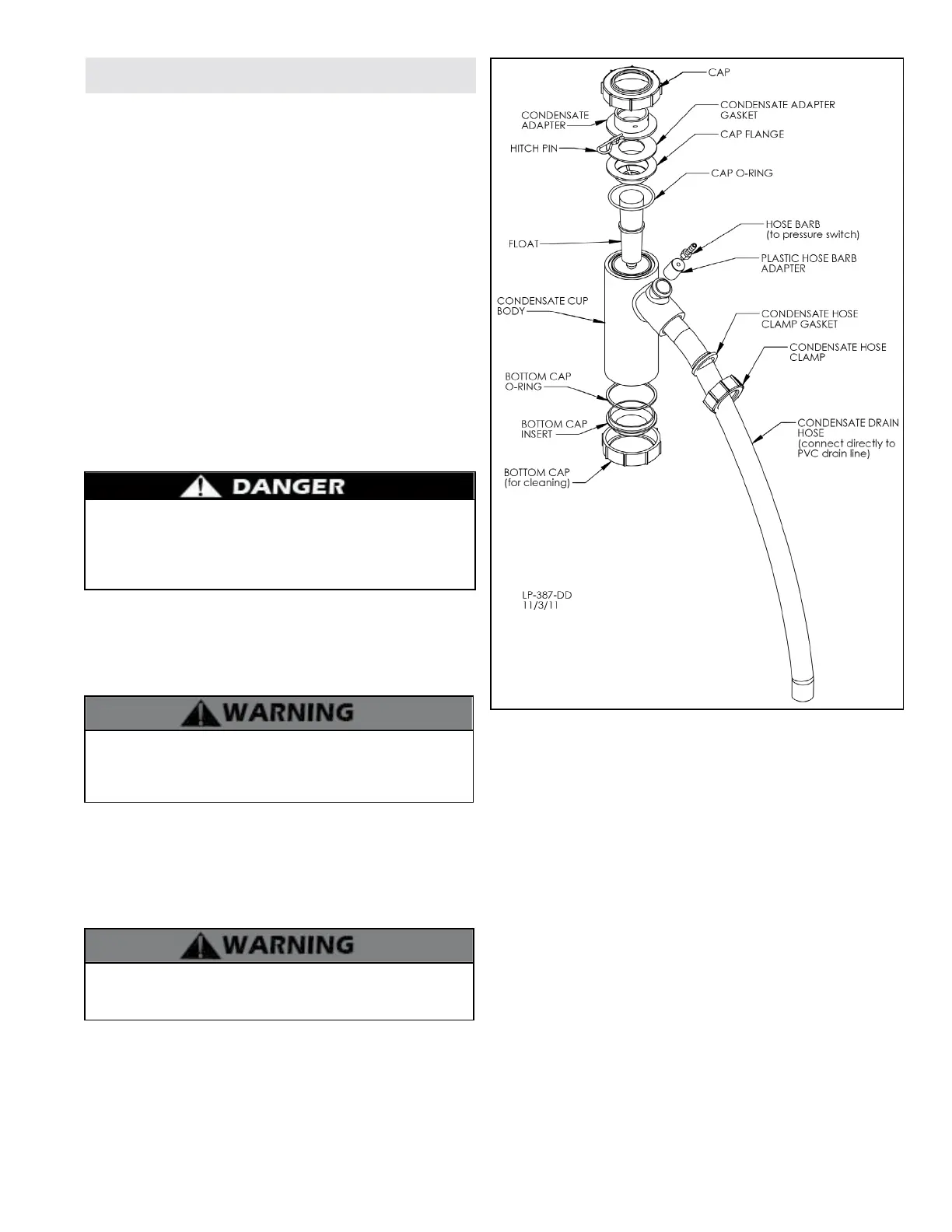

Figure 24 - Condensate Trap Detail

Condensate Trap Installation Instructions

The condensate trap assembly MUST BE PROPERLY INSTALLED

according to these instructions when operating the boiler.

Operating the boiler without the condensate trap assembly will

cause ue gases to leak and result in serious personal injury or

death.

1. Ensure all parts shown in Figure 24, Condensate Detail, are

included with the condensate trap. If any parts are missing, DO NOT

install the trap. Replace the entire condensate assembly.

NOTE: Before installation, clean out the condensate collector with

water to remove any foreign matter that may block the condensate

line.

Do not install the condensate assembly if a component is lost

or missing. Replace the entire assembly. Failure to follow this

warning could result in property damage, serious personal injury,

or death.

2. NOTE: The installer should ll the condensate trap with tap water

prior to assembly on the boiler.

3. Slide the condensate trap adapter onto the drain tube until the

holes line up with the groove.

4. Insert stainless steel lock pin to lock condensate adapter to the

drain tube.

5. Connect the clear hose from the pressure switch to the hose barb.

Do not operate the boiler without the clear hose attached from

the hose barb to the pressure switch. Failure to follow this warning

could result in property damage, serious personal injury, or death.

NOTE: The use of ¾” PVC or CPVC pipe are acceptable materials for

condensate piping. However, use materials approved by the authority

having jurisdiction.

In the absence of other authority, PVC and CPVC pipe must comply with

ASTM D1785 or D2845. Cement must comply with ASTM D2564 for PVC

or ASTM F493 for CPVC. For Canada, use CSA or ULC certied PVC or

CPVC pipe, ttings, and cement. If pipe is used, deburr and chamfer pipe

to allow proper mating to the drainage assembly.

5. Run condensate drain hose to 1” PVC or CPVC drain pipe. See Figure

26.

NOTE: DO NOT cement drain hose to the PVC drainage pipe!

NOTE: To allow for proper drainage on long horizontal runs, a second

line vent may be required and tubing size may need to increase to

1”. Failure to add a second vacuum break could result in condensate

backup, improper boiler operation, and nuisance shutdowns.

NOTE: See Part 14, this manual, for instructions on how to maintain the

condensate trap.

Part 6 - Condensate Removal

Loading...

Loading...