LP-387 Rev. 011 Rel. 005 Date 1.3.19

50

Boiler Setting Program Navigation

Once the code is conrmed, the user can start to set the Boiler

Settings. Use the arrow keys on the display to navigate through

the Boiler Settings. A blinking setting indicates the setting can be

changed. To change a setting, press ENTER. Boiler settings can be

increased by pressing ^ and decreased by pressing v on the display.

When done, press ENTER. The setting will stop blinking and the

user can move on to next setting. Press RESET to exit programming

and store settings. Listed below are the boiler settings that can be

programmed into the control.

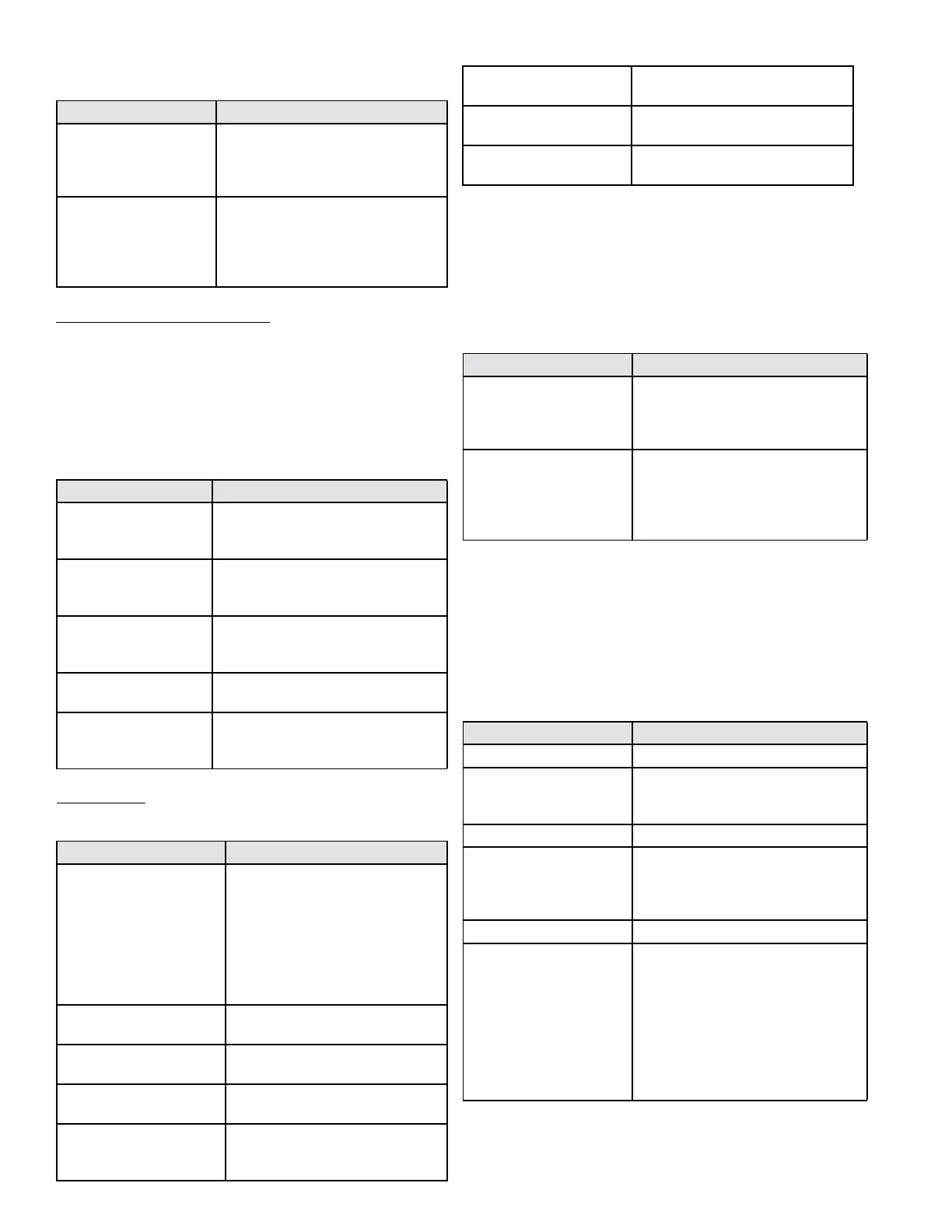

Screen Description

ENTER MENU CODE

000

To access the boiler setting program,

press and hold ENTER for 4 seconds

until the display shows the screen at

left.

ENTER MENU CODE

600

Use the arrow keys to log in the

Boiler Menu Access Code - 600.

Press ENTER to conrm the code and

access the Boiler Setting Program

navigation menu.

Table 17 - Boiler Setting Access

Screen Description

CENTRAL HEAT

180

o

F

Allows the user to adjust the boiler

set point from 50F to 190

o

F (Factory

Default 180

o

F).

CENTRAL DIFF SET

30

o

F

Adjusts the boiler dierential set point

from 5

o

F to 30

o

F (Factory Default

30

o

F).

DHW SETPOINT

119

o

F

Adjusts the indirect tank set point

from 70

o

F to 185

o

F (Factory Default

119

o

F).

DHW DIFF SETPOINT

7

o

F

Adjusts the DHW dierential set point

from 1

o

F to 30

o

F (Factory Default 7

o

F).

TEMP DISPLAY C OR F

o

F

Adjusts the temperature measurement

in F = Fahrenheit to C = Celsius (Default

is Fahrenheit).

Table 18 - Boiler Setting Program Navigation

Clock Settings

(NOTE: The clock will reset if the boiler is powered o for more than

a week.)

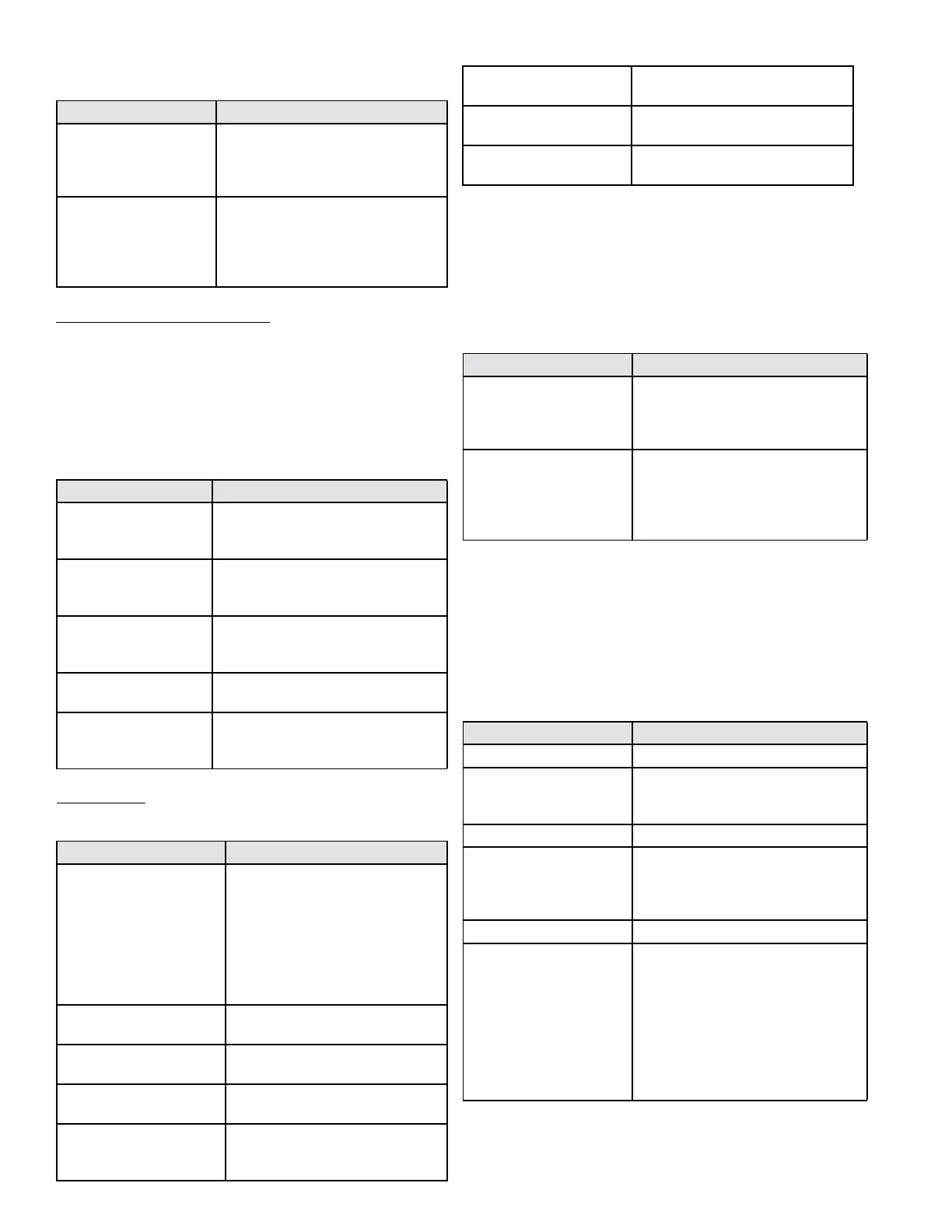

Screen Description

CLOCK MODE (12/24)

08/28/2009 Fr 9:42A

Changes the clock from 12 hour

mode (8:45 PM) to 24 hour mode

(20:45). To change to 24 hour mode,

press ENTER. The letter (A or P) after

the time will blink. Press the up or

down arrow key once and the letter

will disappear. Press ENTER to save

the new setting.

CLOCK HOUR

08/28/2009 Fr 10:01A

Allows the user to adjust the hour

setting.

CLOCK MINUTE

08/28/2009 Fr 10:01A

Adjusts the minute setting.

CLOCK DAY OF WEEK

08/28/2009 Fr 10:01A

Adjusts the day of the week.

CLOCK DATE MODE

08/28/2009 Fr 10:01A

Allows the user to switch to

European date format (2009/08/28)

from US format (08/28/2009).

CLOCK YEAR

08/28/2009 Fr 10:01A

Adjusts the year setting.

CLOCK MONTH

08/28/2009 Fr 10:01A

Adjusts the month setting.

CLOCK DATE

08/28/2009 Fr 10:01A

The clock is set.

Table 19 - Clock Setting Screens

NOTE: The internal clock does not adjust for daylight savings time and

requires manual adjustment.

E. Programming the System Setting

System Setting Program Access

Note: Programming the boiler control is not possible when the boiler

is ring. Make sure any input which can create a demand on the boiler,

such as the tank thermostat, is turned o, so the boiler will remain idle

to allow programming.

Screen Description

ENTER MENU CODE

000

To access the boiler setting program,

press and hold ENTER for 4 seconds

until the display shows the screen at

left.

ENTER MENU CODE

925

Use the arrow keys to log in the Boiler

Menu Access Code - 925. Press ENTER

to conrm the code and access the

System Setting Program navigation

menu.

Table 20 - System Setting Access

F. System Setting Program Navigation

Once the System Menu Access Code is conrmed, the user can

begin to set the system setting menu. Use the < > keys on the display

to navigate through the System Settings. To change a setting, press

ENTER. System settings can be increased by pressing ^ and decreased

by pressing v on the display. When done, press ENTER. The setting will

stop blinking and you can move on to next setting. Press RESET to exit

programming and store settings. Listed below are the boiler settings

that can be programmed into the control.

Screen Description

Function 1 Factory Program Mode

MODE

INDIRECT 1

This indicates that the control is

congured correctly. Do not change

this setting.

Function 3 DHW Tank Max Temp

DHW TANK MAX TEMP

180

o

F 3

This is the maximum temperature that

can be selected in boiler settings for

the DHW indirect tank. Factory Default

is 180

o

F. (Range: 95

o

F to 180

o

F)

Function 6 DHW Post Pump Time

DHW POST PUMP TIME

0 MINUTES 6

The indirect pump has the ability to

post purge energy from the boiler

to run the pump after the set point

has been achieved. Please note that

running the pump for a time greater

than 5 minutes may cause tank energy

to be released back to the boiler

heat exchanger. Factory Default of 0

Minutes. (Range: 0 – 10 minutes)

the boiler, such as the tank thermostat, is turned o, so the boiler

will remain idle to allow programming.

Loading...

Loading...