LP-387 Rev. 011 Rel. 005 Date 1.3.19

65

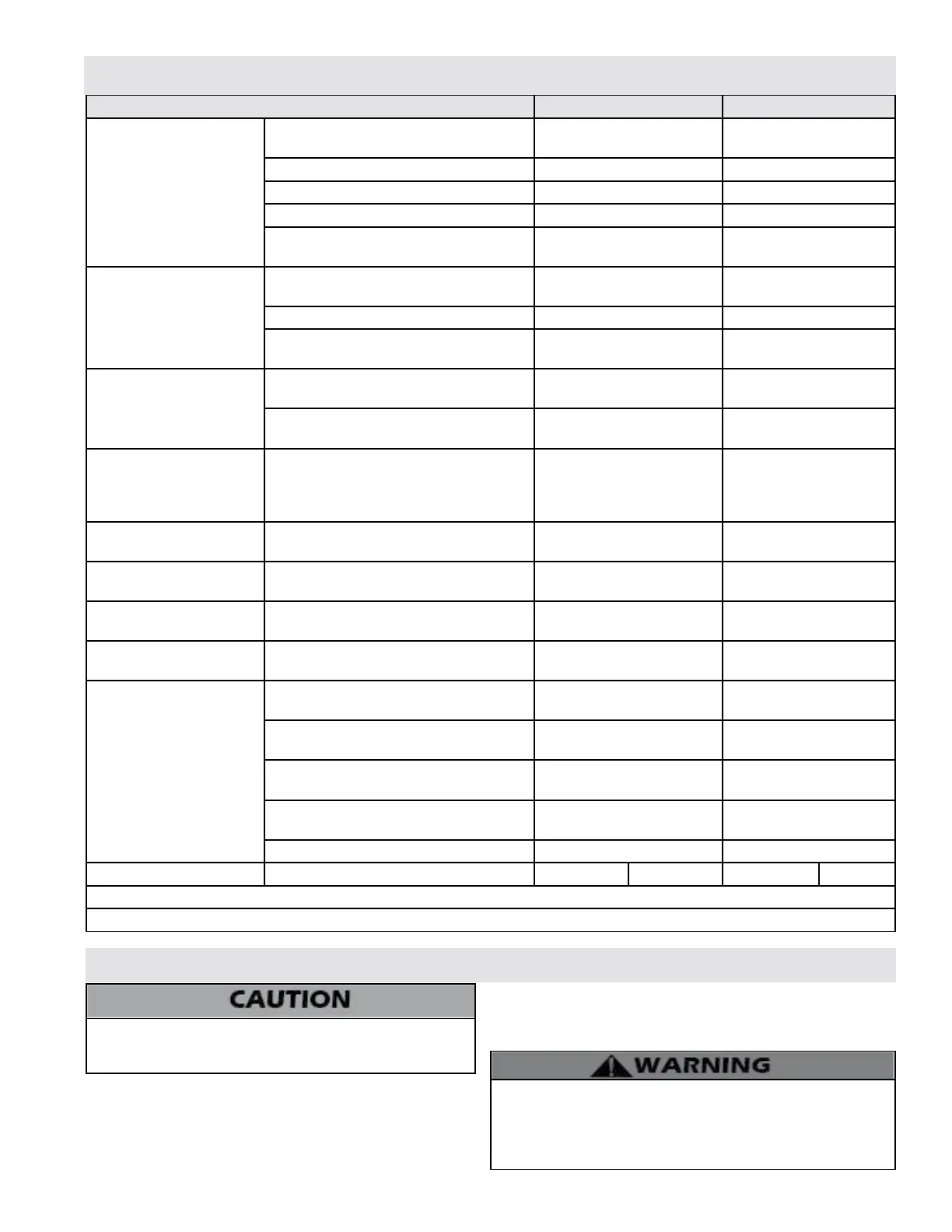

Part 15 - Installation Checklist

Light O Activities Date Completed:

1. Fill the Heating System

Check all piping and gas connections. Verify

all are tight.

Pressurize system. (12 - 15 psi) PSI

Add water to prime condensate cup.

Percentage of glycol in system (0 - 50%) %

Verify near boiler piping is properly

supported.

2. Check Gas Pipe

Leak test using locally approved methods

(consult jurisdictional code book).

Check incoming gas pressure (3.5 to 14” WC). Static WC

Check the “drop” on light o (less than 1”

WC).

Dynamic WC

3. Check Combustion

Check and adjust (if necessary) carbon

dioxide content.

%CO2 High Fire %CO2 Low Fire

Check and adjust (if necessary) carbon

monoxide content.

ppm CO High Fire ppm CO Low Fire

4. Check Electrical

Connections

Ensure all electrical connections of line

voltage (pumps, etc.) and low voltage

circuits (system sensor, outdoor sensor, etc.)

are properly wired.

5. Verify System Operation

Turn up thermostat to verify wiring

connections.

6. Record Ionization

Current

Check uA reading at d7 on the status menu

(see Start-Up section, this manual).

uA High Fire uA Low Fire

7. Indirect Water Heater

Verify safety and operation of the indirect

water heater. Record settings.

DHW Setpoint DHW Dierential

8. Mixing Valve

If necessary, ensure thermostatic mixing

valve is properly supported and installed.

9. Convert the Boiler

If necessary, convert the boiler to the proper

fuel type.

Locate the stickers in the appropriate

locations on the boiler.

Verify combustion settings after gas

conversion - Carbon Dioxide.

%CO2 High Fire %CO2 Low Fire

Verify combustion settings after gas

conversion - Carbon Monoxide.

ppm CO High Fire ppm CO Low Fire

Mail in conversion registration.

10. Record heating curve. Record steps *8 *9 *10 *11

Notes:

Table 31 - Installation Checklist

Allowing the boiler to operate with a dirty combustion chamber will

hurt operation. Failure to clean the heat exchanger as needed by the

installation location could result in boiler failure, property damage,

personal injury, or death. Such product failures ARE NOT covered

under warranty.

In unusually dirty or dusty conditions, care must be taken to keep

boiler cabinet door in place at all times. Failure to do so VOIDS the

warranty.

The boiler requires minimal periodic maintenance under normal

conditions. However, in unusually dirty or dusty conditions, periodic

vacuuming of the cover to maintain visibility of the display and

indicators is recommended.

Periodic maintenance should be performed once a year by a qualied

service technician to assure that all the equipment is operating

Part 16 - Maintenance Report

safely and eciently. The owner should make necessary arrangements

with a qualied heating contractor for periodic maintenance of the

boiler. Installer must also inform the owner that the lack of proper care

and maintenance of the boiler may result in a hazardous condition.

Loading...

Loading...