LP-387 Rev. 011 Rel. 005 Date 1.3.19

41

Failure to use the correct sensor may result in tank temperature

being either above or below set point, and could result in decreased

performance, substantial property damage, or heightened risk of

injuries due to scalds.

Caution should be used to ensure neither of these terminals becomes

connected to ground. Failure to do so can result in property damage,

personal injury, or death.

NOTE: If sensor wires are located in an area with sources of potential

electromagnetic interference (EMI), the sensor wires should be

shielded, or the wires routed in a grounded metal conduit. If using

shielded cable, the shielding should be connected to the common

ground of the boiler.

K. Optional UL353 Low Water Cut-

O Interface Kit

If an optional UL 353 Low Water Cut-O

(LWCO) Interface Kit is used, the control

box of the kit should be mounted to the

left side of the boiler cabinet near the low

water cut-o probe, which is located on

the outlet nipple of the boiler.

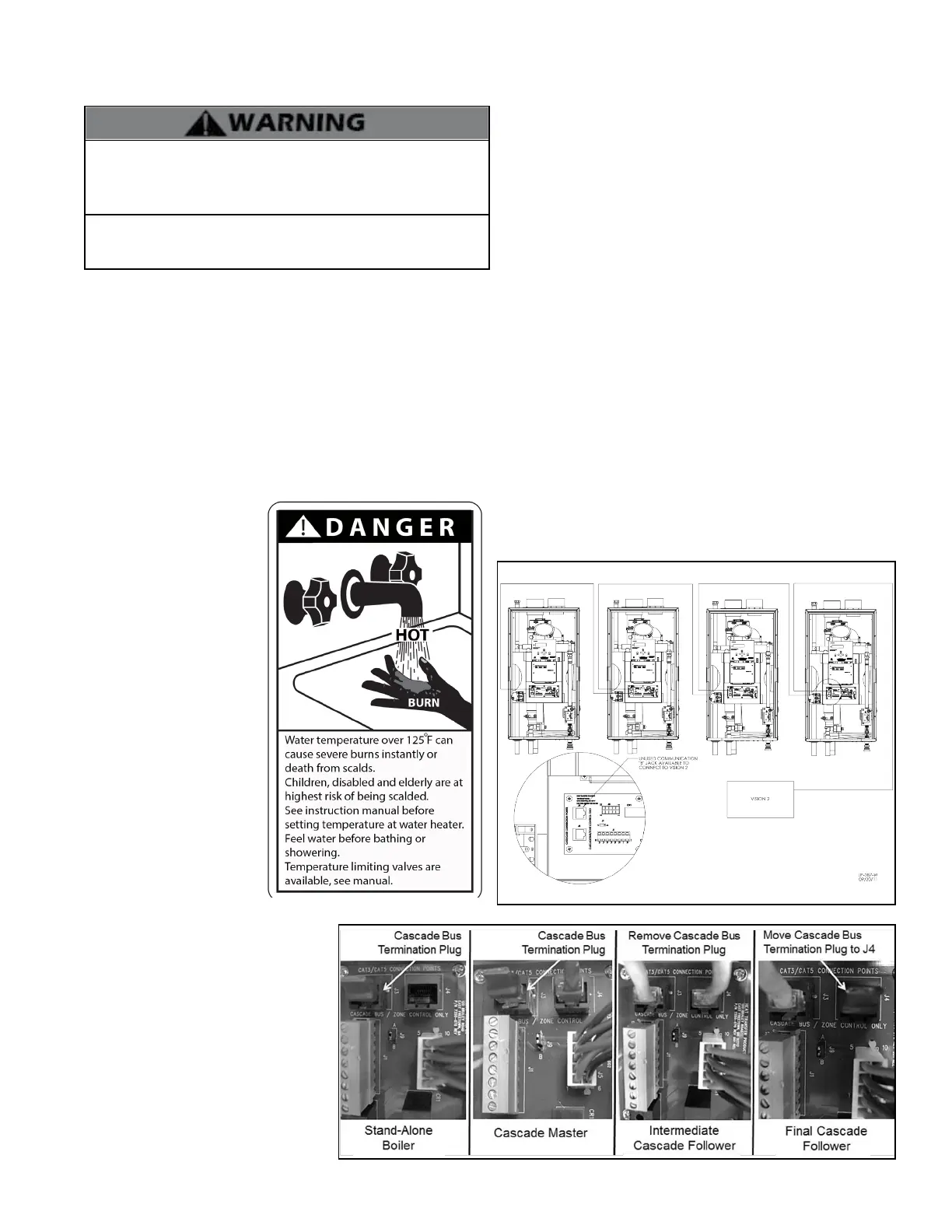

L. Wiring of Cascade System Communication Bus

1. A Cascade Bus Termination Plug has been installed on the

customer connection board of this boiler. The purpose of this plug

is to stabilize communication between multiple boilers and reduce

electrical “noise”. See Figures 30 and 31 for Cascade Bus Termination

Plug installation detail.

2. Use standard CAT3 or CAT5 computer network patch cables to

connect the communication bus between each of the boilers. These

cables are readily available at any oce supply, computer, electronic,

department or discount home supply store in varying lengths. If you

possess the skills you can also construct custom length cables.

3. It is recommended to use the shortest length cable that will

reach between the boilers and create a neat installation. Do not run

unprotected cables across the oor where they may become wet

or damaged. Avoid running communication cables parallel and

close to or against high voltage (120 volt or greater) wiring. HTP

recommends that the maximum length of communication bus

cables not exceed 200 feet.

4. Route the communication cables through one of the knockouts

in the cabinet.

Figure 30 - Wiring Cascade System

Figure 31 - Cascade Termination Plug Detail

J. Optional 0-10 Volt Building Control Signal

1. A signal from a building management system may be connected to

the boiler to enable remote control. This signal should be a 0-10 volt

positive-going DC signal. When this input is enabled using the installer

menu, a building control system can be used to control the set point

temperature of the boiler. The control interprets the 0-10 volt signal as

follows; when the signal is between 0 and 1.5 volts, the boiler will be

in standby mode, not ring. When the signal rises above 1.5 volts, the

boiler will ignite. As the signal

continues to rise towards its

maximum of 10 volts, the

2. Connect the indirect sensor (7250P-325) to the terminals marked

DHW SENSOR (shown in Figures 29 and 32) in the electrical junction

box.

boiler will increase in set

point temperature. See Part

10 for details on the setting of

function 16.

2. Connect a building

management system or other

auxiliary control signal to the

terminals marked 16, 0-10

VOLT + and 17, 0-10 VOLT –

in the electrical junction box

(shown in Figure 29). Caution

should be used to ensure that

the 0-10 VOLT + connection

does not become connected

to ground.

3. Move jumper on connection

board (shown in Figure 31)

from A to B.

4. See Function 17 this manual

to program the 0-10 volt

signal.

NOTE: When a 0-10 volt building management system is installed,

Follow the complete instructions included in the kit for proper

installation.

NOTE: The control system senses system water temperatures

entering and exiting the heat exchanger to provide protection

against low water conditions. Where local codes or jurisdictions

do not accept a pressure device for low water protection, the

jurisdictions may accept these control functions as a means of

providing low water protection.

the return sensor temperature cannot be

monitored through the appliance display.

NOTE: Ensure that the polarity of the

connections from the external modulating

boiler controller to the boiler is correct.

Reversed polarity could lead to erratic and/

or no response from the boiler controller.

Loading...

Loading...