LP-387 Rev. 011 Rel. 005 Date 1.3.19

44

Part 8 - Gas Connections

Failure to follow all precautions could result in re, explosion, severe

injury, or death.

It is very important that you are connected to the type of gas noted

on the rating plate. “LP” for liqueed petroleum, propane gas, or

“NG” for natural or city gas. Do not do a gas conversion without

an approved gas conversion kit. Prior to turning the gas on, all gas

connections must be approved by the local gas supplier or utility, in

addition to the governing authority.

A gas conversion kit comes with the boiler. Follow the included

instructions VERY carefully if converting the boiler. Failure to follow

gas conversion instructions could result in property damage, serious

injury, or death.

The gas supply shall have a minimum of no less than 3.5” water column,

a maximum inlet pressure of no greater than 14” water column (350

mm), and ½ pound pressure (3.5 kPa). The entire piping system, gas

meter, and regulator must be sized properly to prevent excessive

pressure drop (greater than 0.5” WC) as stated in the National Fuel Gas

Code. This information is listed on the rating plate.

UL recognized fuel gas detectors are recommended in all enclosed

propane and natural gas applications where there is a potential for

an explosive mixture of fuel gas to accumulate. The installation of

these detectors should be made in accordance with the detector

manufacturer’s recommendations, and/or local laws. Failure to install

fuel gas detectors in these applications could result in re, explosion,

property damage, severe personal injury, or death.

A. Gas Piping

1. Run the gas supply line in accordance with all applicable codes.

2. Locate and install manual shuto valves in accordance with state

and local requirements.

3. In Canada, the Manual Shuto must be identied by the installing

contractor.

4. It is important to support gas piping as the unit is not designed to

structurally support a large amount of weight.

5. Purge all gas lines thoroughly to avoid start up issues with air in the

lines.

6. Sealing compound must be approved for gas connections. Care

must be taken when applying compound to prevent blockage or

obstruction of gas ow which may aect the operation of the unit.

Support gas supply piping with hangers, not by the boiler or its

accessories. The boiler gas valve and blower will not support the

weight of the piping. Make sure the gas piping is protected from

physical damage and freezing, where required. Failure to follow

these instructions could result in gas leakage, and result in re,

explosion, property damage, severe personal injury, or death.

Do not use Teon tape on gas line pipe thread. Use a pipe

compound rated for use with natural and propane gases. Apply

sparingly on male pipe ends, leaving the two end threads bare

and ow unobstructed. Failure to follow these instructions could

result in gas leakage or blockage, and result in re, explosion,

property damage, severe personal injury, or death.

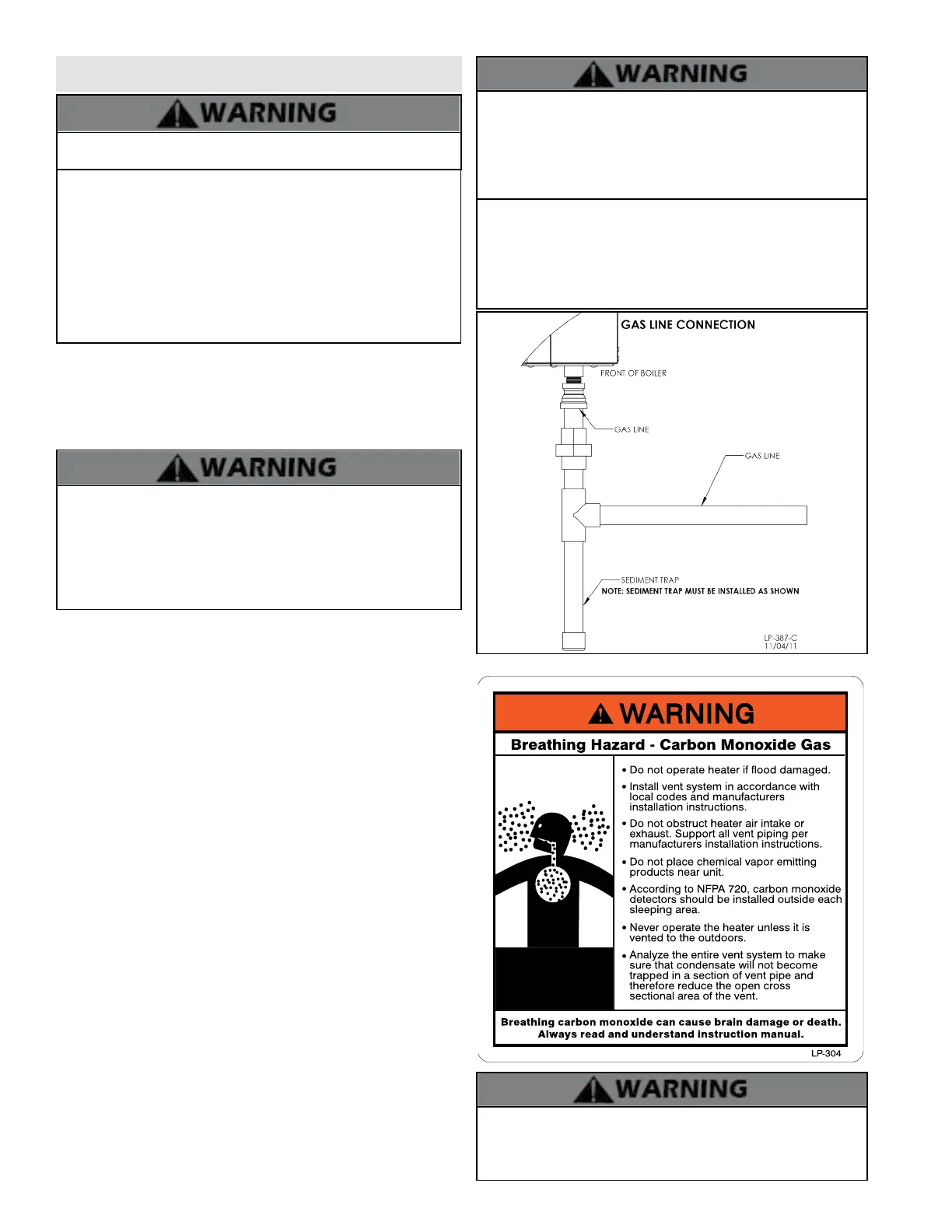

Figure 34 - Gas Connection

The gas connection on the boiler is 3/4”. It is mandatory that this tting

is used for connection to a eld fabricated drip leg as shown in the

illustration per the National Fuel Gas Code. You must ensure that the

entire gas line to the connection at the boiler is no smaller than the

unit supplied connection.

Once all inspections have been performed, the piping must be leak

tested. If the leak test requirement is a higher test pressure than the

maximum inlet pressure, you must isolate the boiler from the gas line.

In order to do this, shut the gas o using factory and eld-installed gas

cocks. This will prevent high pressure. Failure to do so may damage the

gas valve. In the event the gas valve is exposed to a pressure greater

than ½ PSI, 14” w.c. (3.5 kPa), the gas valve must be replaced. Never use

an open ame (match, lighter, etc.) to check gas connections.

Never use an open ame (match or lighter) to check for gas

leaks. Use a soapy solution to test connection. Failure to use a

soapy solution test or check gas connection for leaks can result

in substantial property damage, severe personal injury, or death.

Loading...

Loading...