Underwater Gear

6.1

This section will detail those components which are sub-

merged or generally under water. We will organize these

components into the following categories:

Mechanical propulsion components

Steering components

Intakes and discharge skin fittings

Monitoring equipment

Anchoring and Windlass (optional)

Keel

6.1 Mechanical Propulsion Components

Keep clear of moving parts at all times. Protect

moving parts from impact during normal use.

Propulsion components are those involved in the move-

ment of your boat.

6.1.1 Propeller

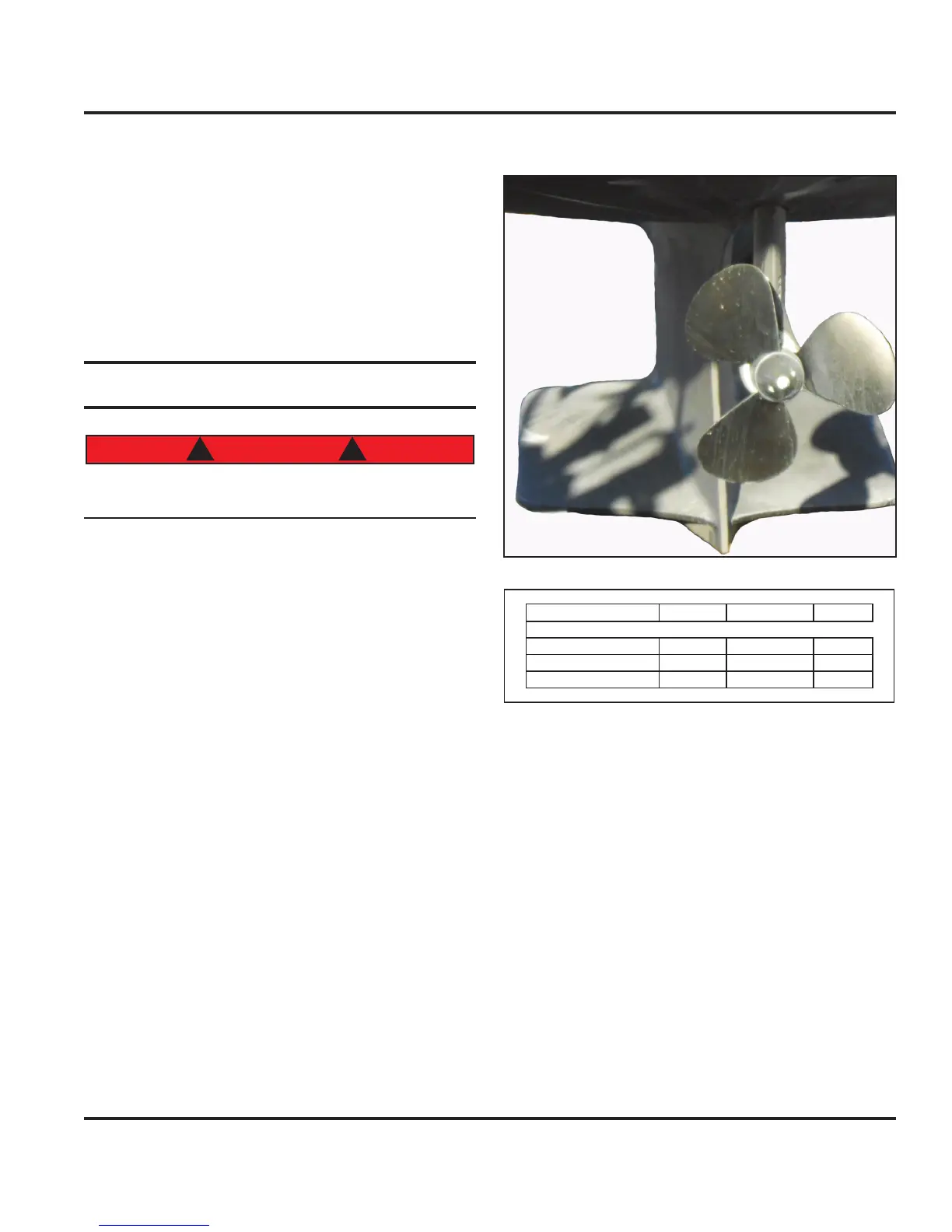

The propeller supplied with your boat (Fig. 6.1 saildrive

example) has been selected as the best propeller for

average use. Propellers use “pitch” as part of its speci-

fications and determines the amount of power exerted

from your engine. Pitch is the displacement resulting

from a 360 degree revolution of the propeller. A 16” pitch

means a 16” advancement from a complete spin of the

propeller. Do not change the pitch of your propellers

without getting your dealer’s recommendations first. If

you change to a different propeller pitch, do NOT use a

propeller which allows the engine to operate at a higher

than recommended RPM. Your engine OEM manual will

specify the maximum recommended RPM.

To maintain rated power, propellers should be free of

nicks, excessive pitting and any distortions that alter them

from their original design. Badly damaged propellers

should be replaced, but those that are chipped, bent or

merely out of shape can be reconditioned by your marine

dealer.

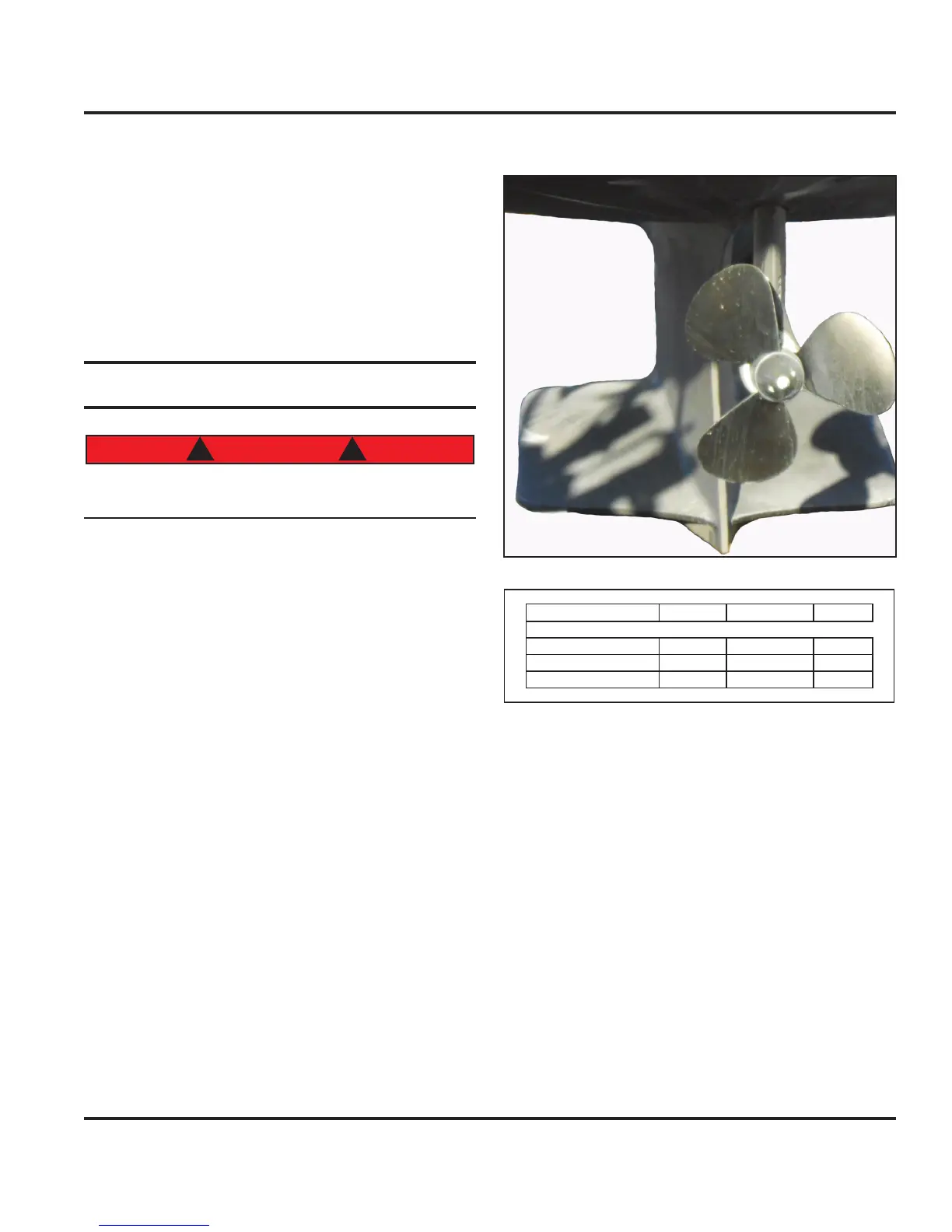

Consider keeping an extra propeller on your boat (see

Fig. 6.2 for propeller specs). If the installed propeller

becomes damaged, it can be replaced with the spare

without major disruption to your outing. We recommend

the replacement procedure be performed by competent

1.

2.

3.

4.

5.

6.

professionals.

Figure 6.1

CONFIGURATION BLADES DIAMETE

PITCH

29 HP 2 16" 11"

40 HP 2 17" 16"

40 HP 3 16" 15"

Figure 6.2

6.1.2 Shaft Drive

The 29HP engine (see the Engines and Transmissions

chapter of this manual for additional details about the

engine) utilizes the traditional shaft method of propul

-

sion. The shaft is made of 1 1/4” diameter Aquamet 19

or equivalent stainless steel which has excellent corro-

sion resistance and very high strength. The coupling at

one end of the shaft is bolted to the transmission. The

other end of the shaft is tapered, threaded, and keyed for

installation of the propeller.

The propeller shaft passes through the hull via a shaft

seal followed by a strut mounted to the underside of the

hull which holds and stabilizes the propeller shaft in posi

-

tion. Refer to Fig 6.3 for details of the shaft, shaft seal

strut and propeller assembly.

6.1.2.1 Shaft Alignment

Underwater Gear

6.1

Loading...

Loading...