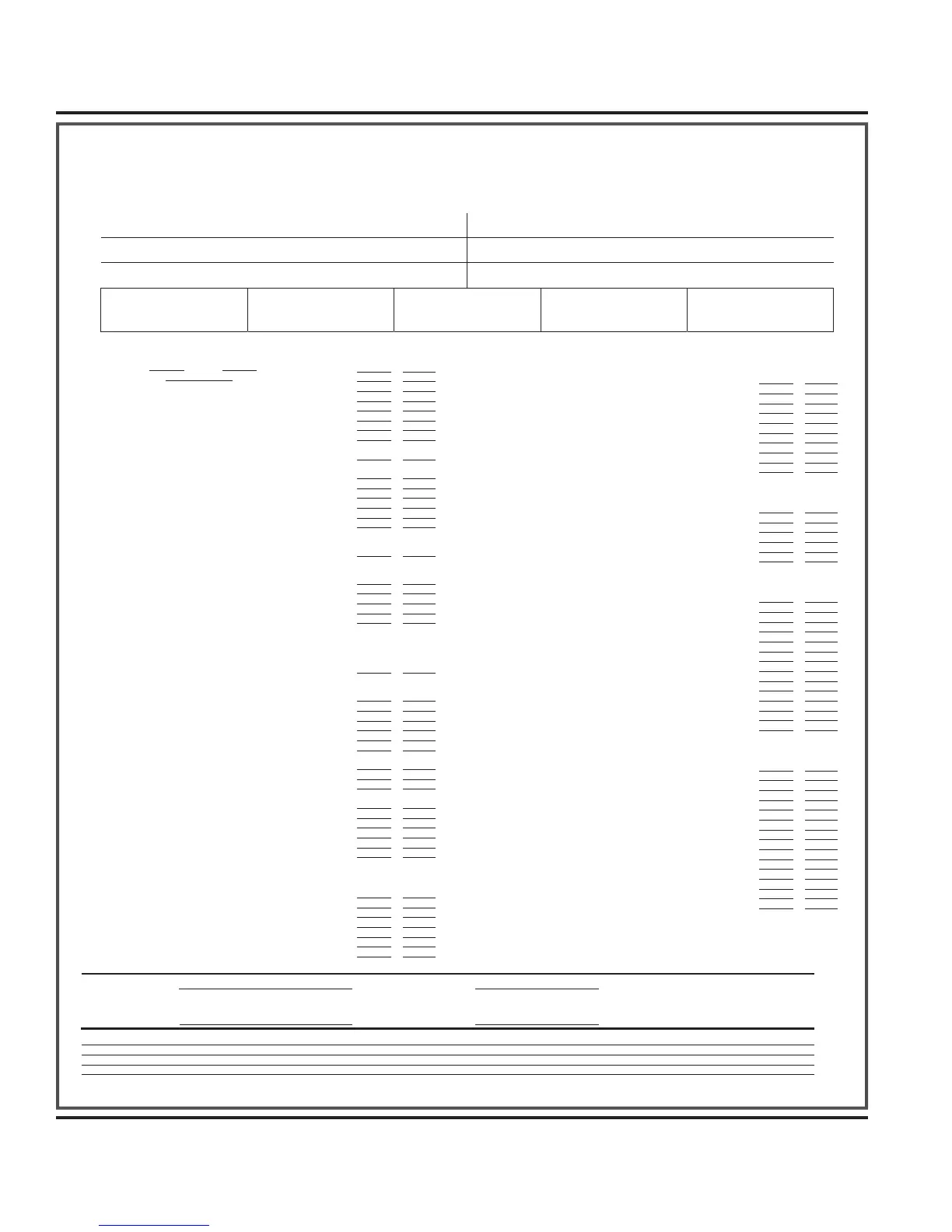

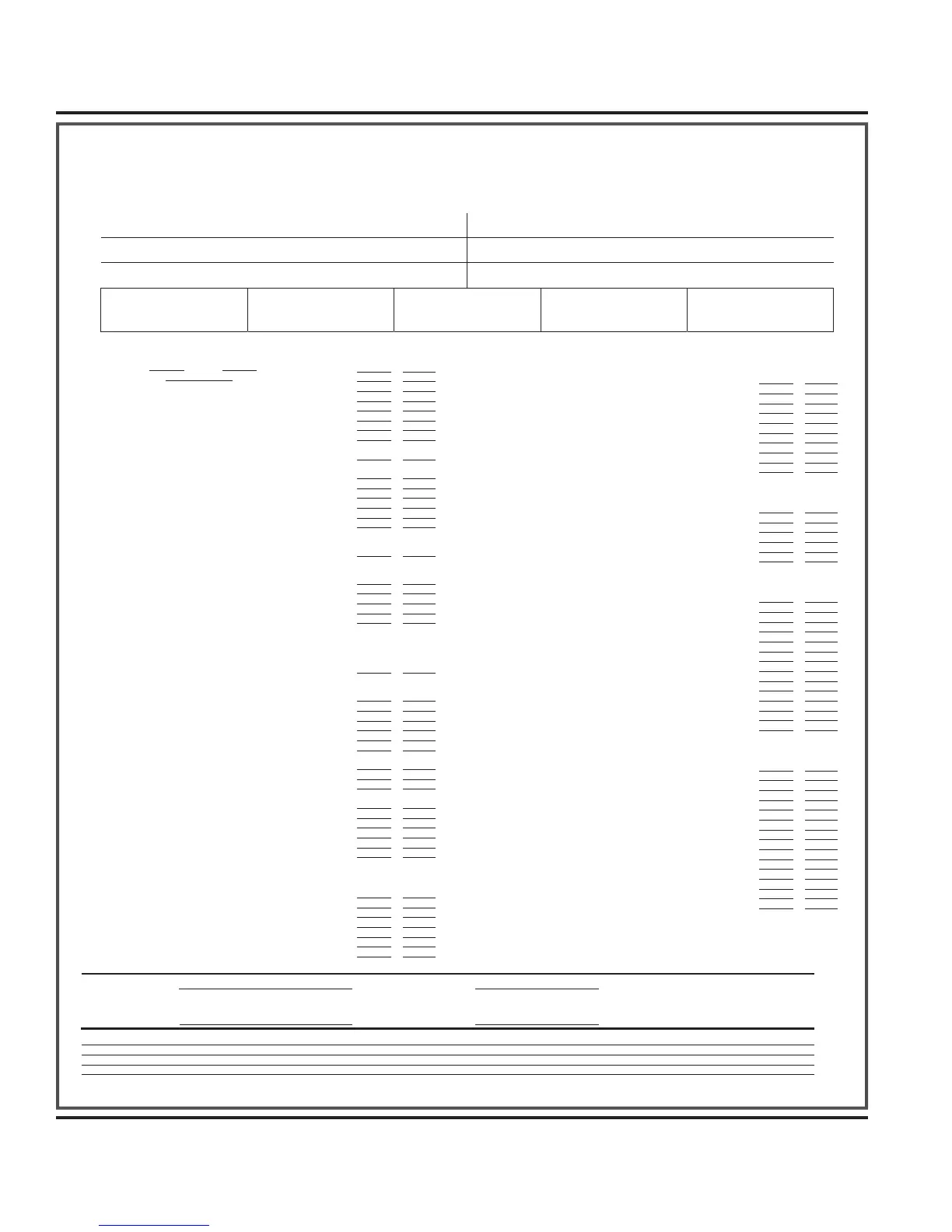

Documents and Forms

2.3

Figure 2.1

MARLOW-HUNTER, LLC

P.O. BOX 1030 – ALACHUA, FL 32616

PRE-DELIVERY

SERVICE RECORD

IMPORTANT: This completed report is required for processing of claims for warranty adjustment. Please forward immediately.

DEALER

NAME

OWNER

NAME

ADDRESS ADDRESS

CITY STATE/ZIP CITY STATE/ZIP

HULL # YEAR SIZE ENG # ENGINE MAKE

BEFORE LAUNCH PROCEDURE:

DEALER OWNER

1. Prop Size

Shaft Size

2. Prop Rotation

3. Prop installed property with cotter pin in shaft

4. Shaft turns freel

5. Shaft aligned in shaft log tube

6. Shaft alignment in relation to strut

7. Engine intake thru hull clear and installed properl

8. Pet-cocks closed on engine

9. Rudder swings freely

no binding or hard spots

(check with wheel)

10. Emergency tiller steering system, complete operational check

with owner

11. Primary steering system, complete operational check

12. Cockpit seat hatches lift smoothl

13. Companionway sliding hatch and door works smoothl

14. Check keel bolts for tightness

15. Hook up and tighten battery cables

16. Check hose clamps on engine pickup, engine exhaust, vanity

drain, galley drain, fresh water system, toilet hoses and bilge

pump – A/C – genset

17. Electrical equipment operational:

( ) Running lights ( ) Cabin lights ( ) Anchor light

( ) Steaming light ( ) Stern light ( ) Courtesy lights

18. Check bilge pumping system

HF radio operational

20. Mast wire tube properly sealed

21. Check optional dripless packing spring tension & set screws

BOAT IN WATER:

22. Check for leaks: rudder post, shaft log, stuffing box, strut bolts

and keel bolts

23. Check for thru-hull fitting leaks: engine pickup, galley sink

drain, toilet pickup, toilet discharge, knot/depth, A/C,

refrigerator

24. Check windows and deck hardware for leaks

25. Check opening ports and hatches for leaks

26. Check rub rail and deck joints for leaks

27. 110 dockside cord and receptacles O

28. Toilet operates OK, intake open, outlet open, pumps O

29. Pressure water system operates OK (let pressure stand for 15

minutes to see if pump goes on)

30. Hot water heater operation O

31. Check stove system for leaks per manufacture

’s instructions

32. With fuel tank full, no leaks at fill pipe, overflow vent or any fuel

line connections or gauge

33. Drawers work smoothl

35. Engine aligned .004 or less

36. Check and tighten all engine mount attachments

37. Check and tighten all engine flange and coupling bolts

BEFORE STARTING ENGINE:

38. Throttle control cable travel and brackets O

39. Clutch control cable travel and brackets O

40. Crank case oil level at full mark

41. Transmission oil level at full mark

42. Engine shut off O

43. Engine water pickup O

44. Bleed air out of fuel line

45. Check heat exchanger fluid level and overflow bottle

DEALER OWNER

AFTER STARTING ENGINE:

46. Oil pressure O

47. Water flow out of exhaust

48. Check fuel line connections for leaks

49. No engine water or oil leaks

50. Idling speed OK, Max RPM O

51. Gear shifts work properly

forward, reverse, neutral

52. Instruments register properl

53. Check stuffing box drip rate (3-4/minute)

54. Purge optional dripless packing assembl

55. Hour meter reading properl

OPTIONAL GENERATOR ENGINE:

56. Crank case oil level at full mark

57. Engine wate

pickup open

58. Check heat exchanger fluid level and overflow bottle if supplied

59. Bleed air out of line

60. Check flow out exhaust

61. Hour meter reading properl

RIGGING:

62. Mast steaming light O

63. Spreaders properly secured

64. Shrouds and stays right length

65. Main and jib halyards right length

66. Jib fits properl

67. Main fits and operates properl

68. Topping lift, out haul, reefing system installed properl

69. Install windex

70. Main sheet and blocks O

71. Jib sheet and blocks O

72. Winch handles fit and winches smooth

73. Rigging properly tuned and pinned

74. Furling system operational

75. Traveler arch ground wire installed

FINAL CHECK:

76.

ll accessory equipment on board

77.

ll loose gear on board

78. Owner’s manual on board

79. Warranty registration form completed and signed

80. Owner familiarized with operation and warranty polic

81. Boat properly cleaned, interior and exterio

82. Owner advised to complete component warranty cards

83.

ll plexiglass hatches and ports free of scratches

84.

ll interior wood free of dents, dings and scratches

85. Interior cushions, bedding & curtains clean and free of defects

86. Exterior gelcoat free of defects

87. Fee of water intrusion above and below the water line

88.

ll electronic equipment calibrated and operational

89. Exterior wood free of defects

90. Life lines adjusted and secu

e

Dealer Signature:

Date:

I have received, read and understand completely the Marlow-Hunter Limited Warranty for my boat.

Owner Signature: Date:

DEALER COMMENTS (Refer to check list by item #

Remove 2

n

Copies and Forward Form Intact. DISTRIBUTION: Original

Marlow-Hunter Service Dept., Canary

Loading...

Loading...