MAXX 450D/470D/Diesel Page 11-3

HydraMaster Corporation

1/18/00

OPERATIONAL MAINTENANCE (cont.)

QUARTERLY

1. Change paper element in air cleaner.

2. Check fuel lines.

3. Clean and gap spark plugs.

4. Change coolant.

5. Grease blower bearing fittings.

6. Change oil in blower.

7. Change oil in pump.

SEMI-ANNUALY

1. Inspect chemical pump diaphragm and check valves for wear.

DE-SCALING ( As Required)

Scale deposits on the interior of the heating system can cause a noticeable loss in

heating performance. Deposits of this kind result from hard water deposits, exces-

sive chemical use, improper chemicals, etc. The frequency with which de-scaling

procedures are required will vary. If your area has particularly hard water or you see

evidence of deposits in the water system, you may have to de-scale monthly.

To de-scale your system, add an appropriate de-scaler chemical to your water box.

Circulate it through the heating system. Let it stand. Flush and repeat as necessary.

Clean all screens and strainers, and check them frequently following de-scaling.

NOTE: If you are using T.M. DeScaler through the flow meter, make sure to run clean

water through the flow meter after this procedure.

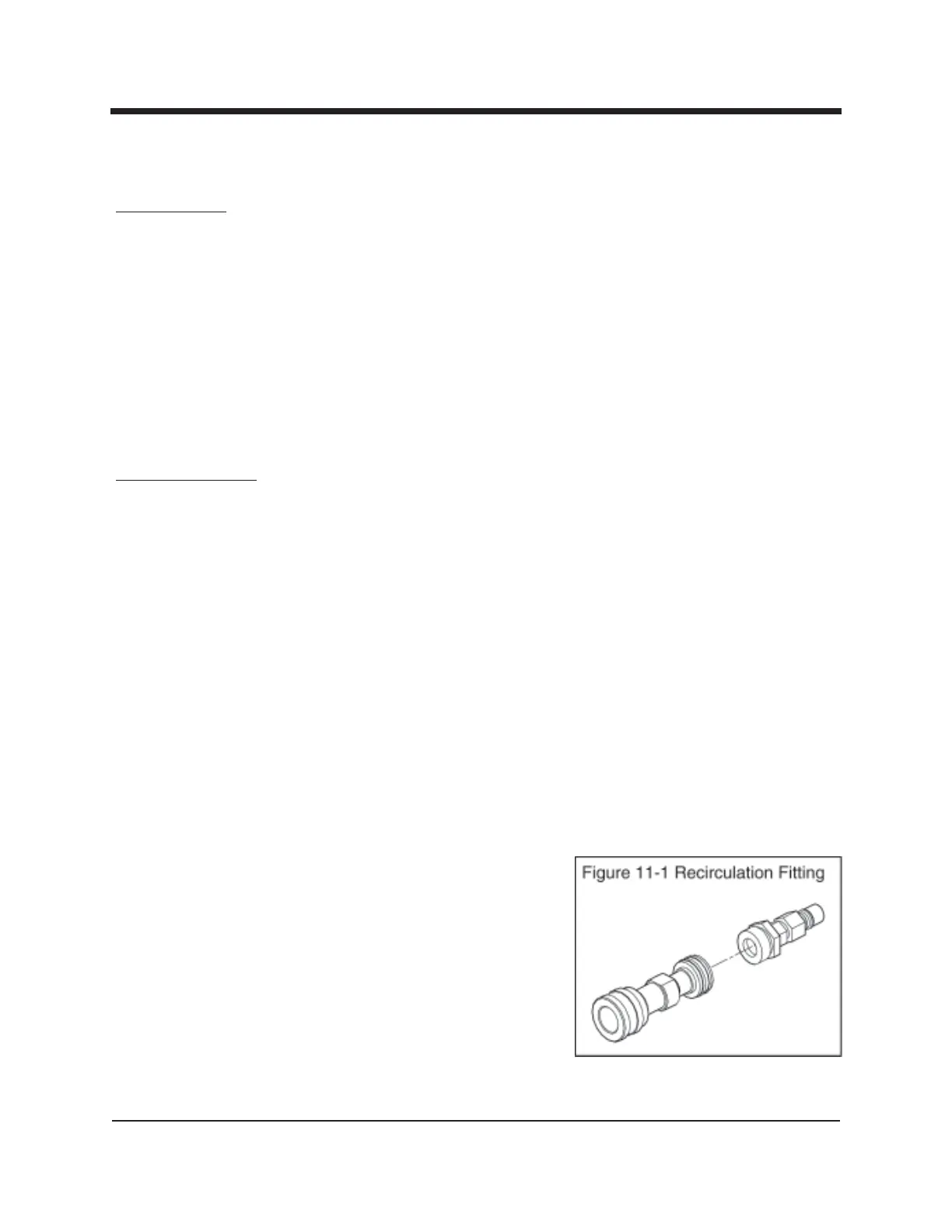

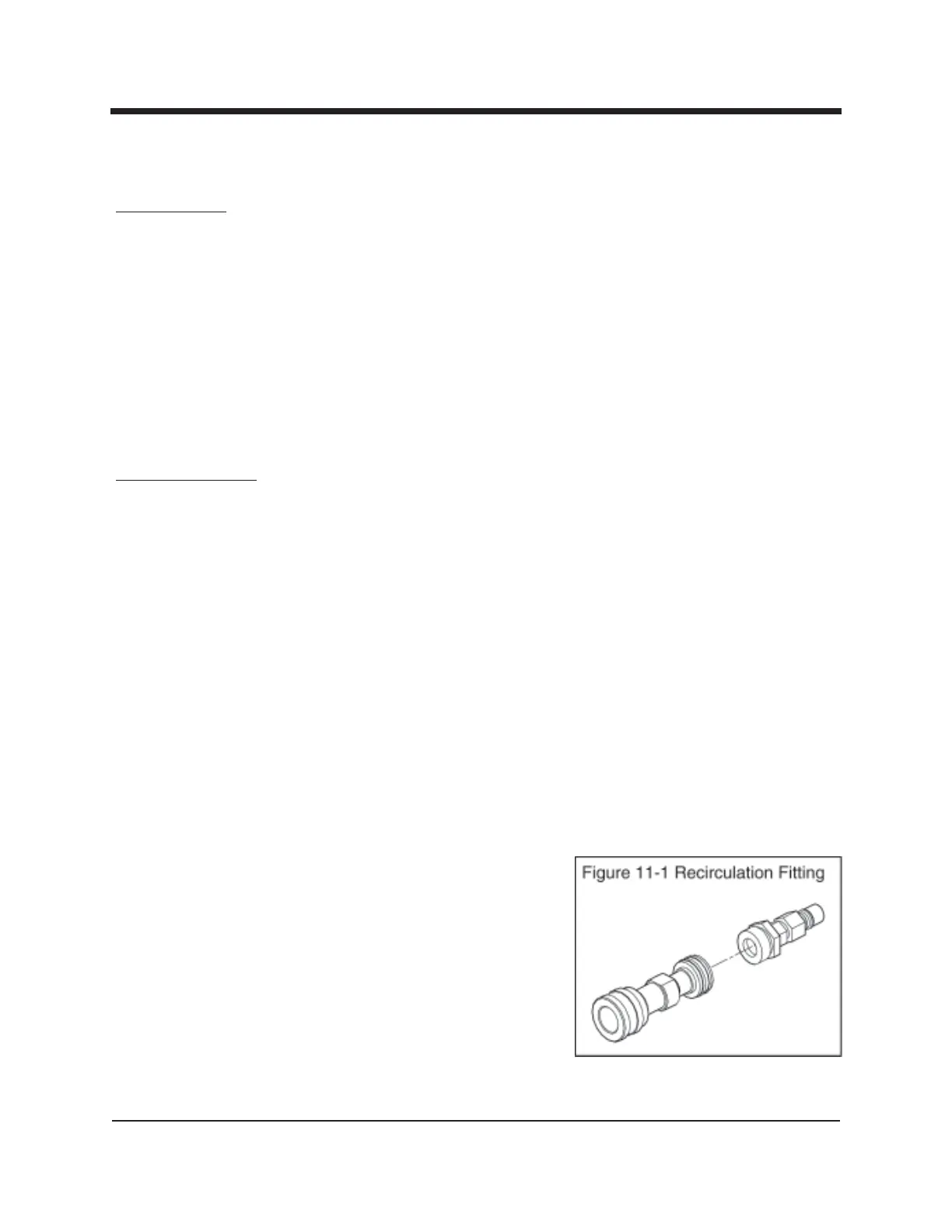

To de-scale using the recirculation kit, start with an

empty water box. Fill a third of te water box with

T.M. DeScaler. Follow the recommendations on the

TM. DeScaler label for proportions. Verify that the

upper float is not lying horizontal, but floats below.

Attach the recirculation fitting provided in the kit to

the garden hose quick connect (see illustration to

right) and this combination to the front of the

machine.

3/30/00

Loading...

Loading...