MAINTENANCE

5-10 HPR130 Manual Gas Instruction Manual

5

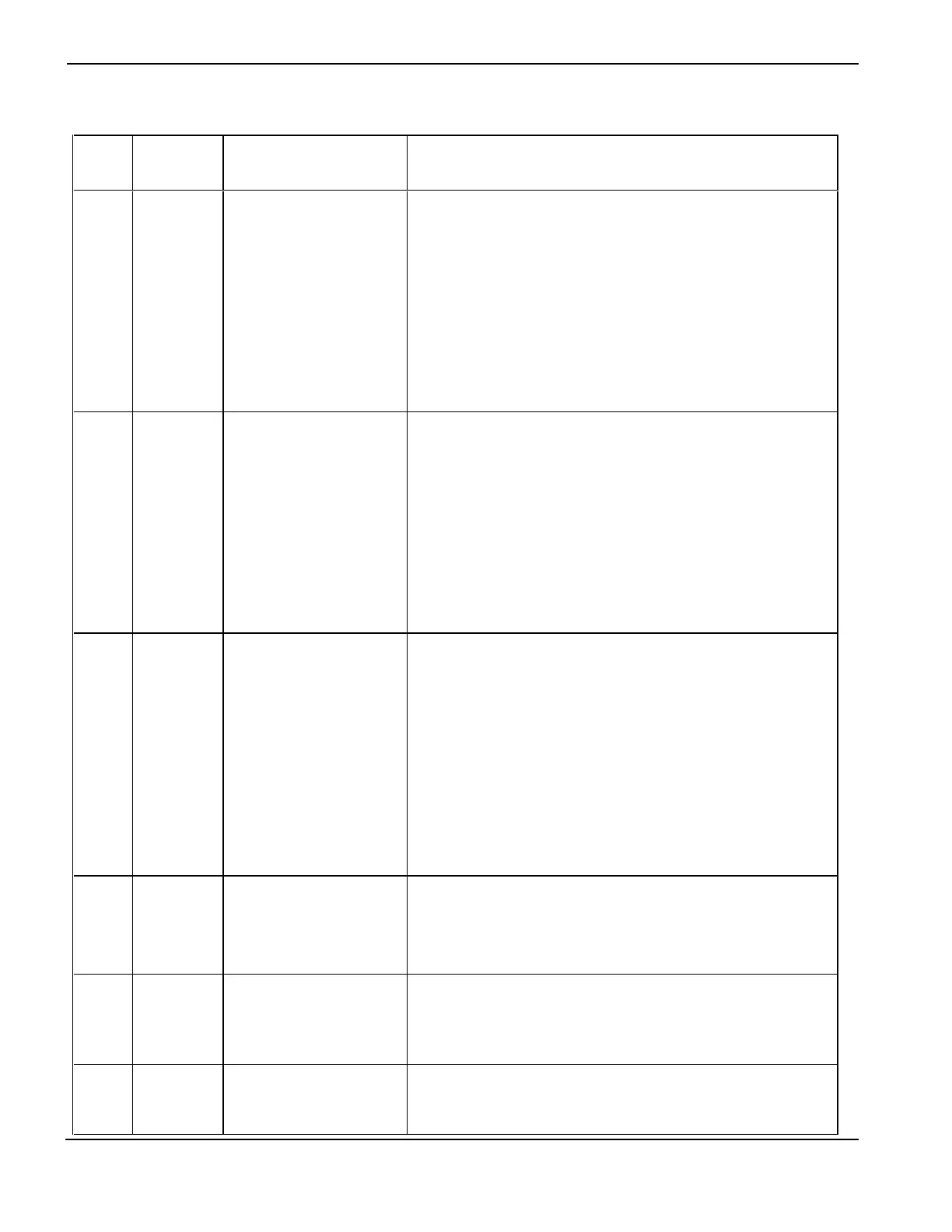

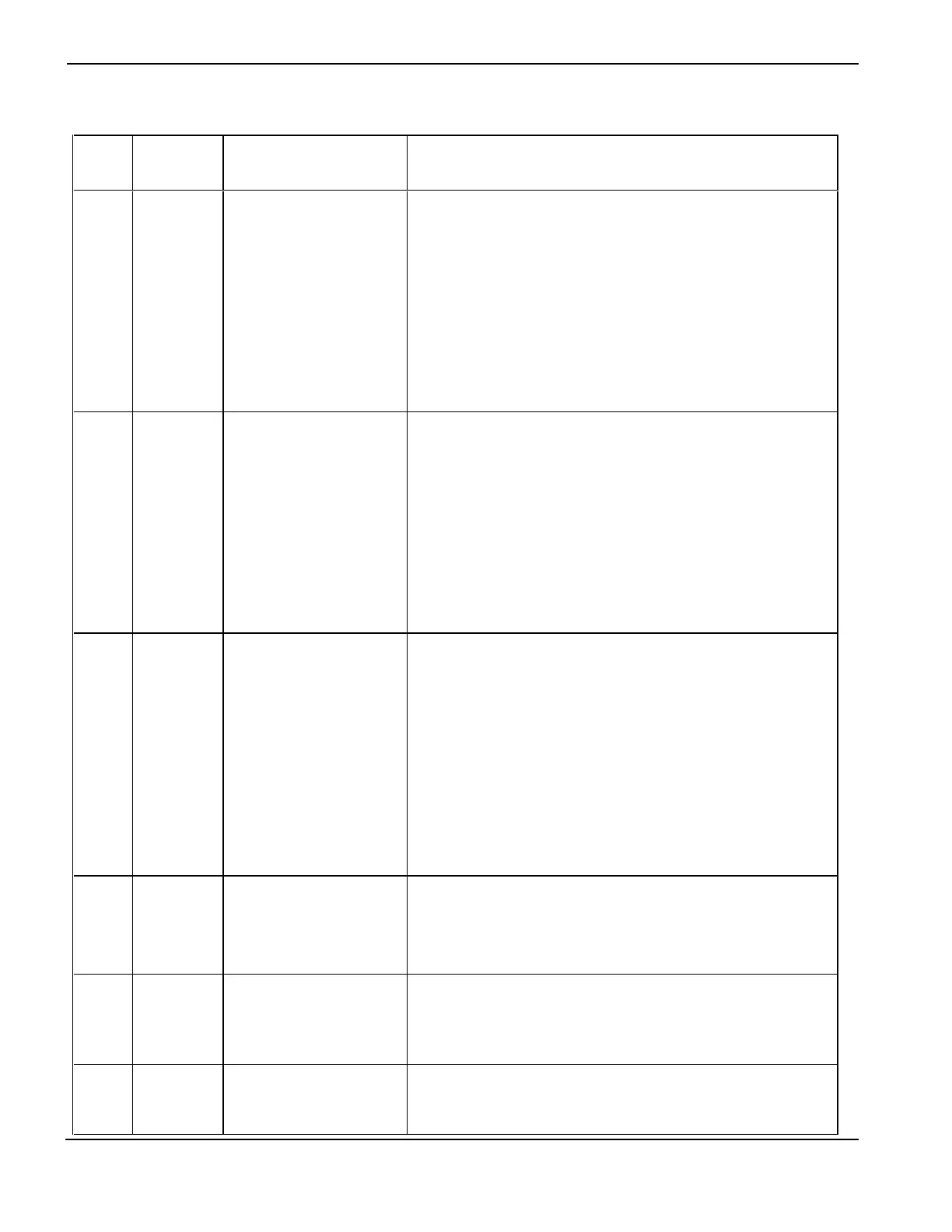

Error code troubleshooting (4 of 6)

Error

code

No.

Name Description Corrective action

1. Verify that both chopper fans are operating properly. Spinning

fan blades should be difficult to see.

2. Blow dust out of system, especially from fans and heat sink

of chopper.

3. Verify that the voltage on back side of J3.201, pins 2 and 10

on PCB3, is less than or equal to 2.9 VDC.

4. If the voltage is low, verify correct wiring between chopper

temp sensor and J3.201 pins 9 and 10.

5. If wiring is good and over temp error does not clear after 30

minutes, replace chopper.

6. If voltage is higher than 2.9 VDC and over temp LED does

not clear after 30 minutes, replace PCB3.

1. Verify that the large fan is operating properly. Spinning fan

blades should be difficult to see.

2. Blow dust out of system especially from fans and large power

transformer.

3. Verify that the voltage on the back side of J3.201 pins 2 and

8, is equal to or less than 3.2 VDC.

4. If voltage is low, inspect wiring between the transformer's

temp sensor and J3.201 pins 7 and 8. Look for shorts to wires

or ground.

5. If wiring is good, the transformer has overheated.

6. If voltage is higher than 3.2 V and over temp error does not

clear after 30 minutes, replace PCB3.

1. Verify that all four fans in the coolant heat exchanger are

running.

2. Blow dust out of the system, especially from the heat

exchanger.

3. Verify that the voltage on the back side of J3.201 pins 2 and

6, is equal to or lower than 2.8 VDC.

4. If voltage is low, inspect wiring between coolant sensor and

J3.201, pins 5 and 6, for shorts to wires or ground.

5. If wiring is good, the coolant has overheated; let system

stand for 30 minutes to cool.

6. If voltage is higher than 2.8 VDC and the over temp error

does not clear after 30 minutes, replace PCB3.

1. If this is a new system, follow start procedure.

2. Verify that the coolant filter is in good condition.

3. Perform coolant flow test procedure (

Maintenance

section).

4.Verify that the CNC drives the plasma start signal for at least

10 seconds to allow the timed-out pump to turn on again.

1. Verify that the temperature sensor for the chopper has not

been jumped out or the wires to the temp switch shorted out in

the harness.

2. If no jumper is present, the chopper is overheated and needs

time to cool to 83° C (181.4° F).

100

Chopper 2

over temp at

power-up

Dipswitch No.1 is not in

the correct position. It is in

the OFF position.

1. For 130 amp systems verify dipswitch No.1 is in the OFF

position.

2. For 260 amp systems repeat step 1 and 2 in error code 99.

65

Chopper

over temp

Chopper has overheated.

67

Magnetics

over temp

Power transformer has

overheated.

71

Coolant over

temp

Torch coolant has

overheated.

93

No coolant

flow

Coolant flow signal was

lost or never was satisfied.

99

Chopper 1

over temp at

power-up

Chopper 1 is indicating an

over temp at power-up.

Loading...

Loading...