120 HyPrecision Predictive waterjet pump Operator Manual 810120

5 – Preventive maintenance

Preventive maintenance

Install the output adapter and the high-pressure poppet assembly

Parts, tools, and materials

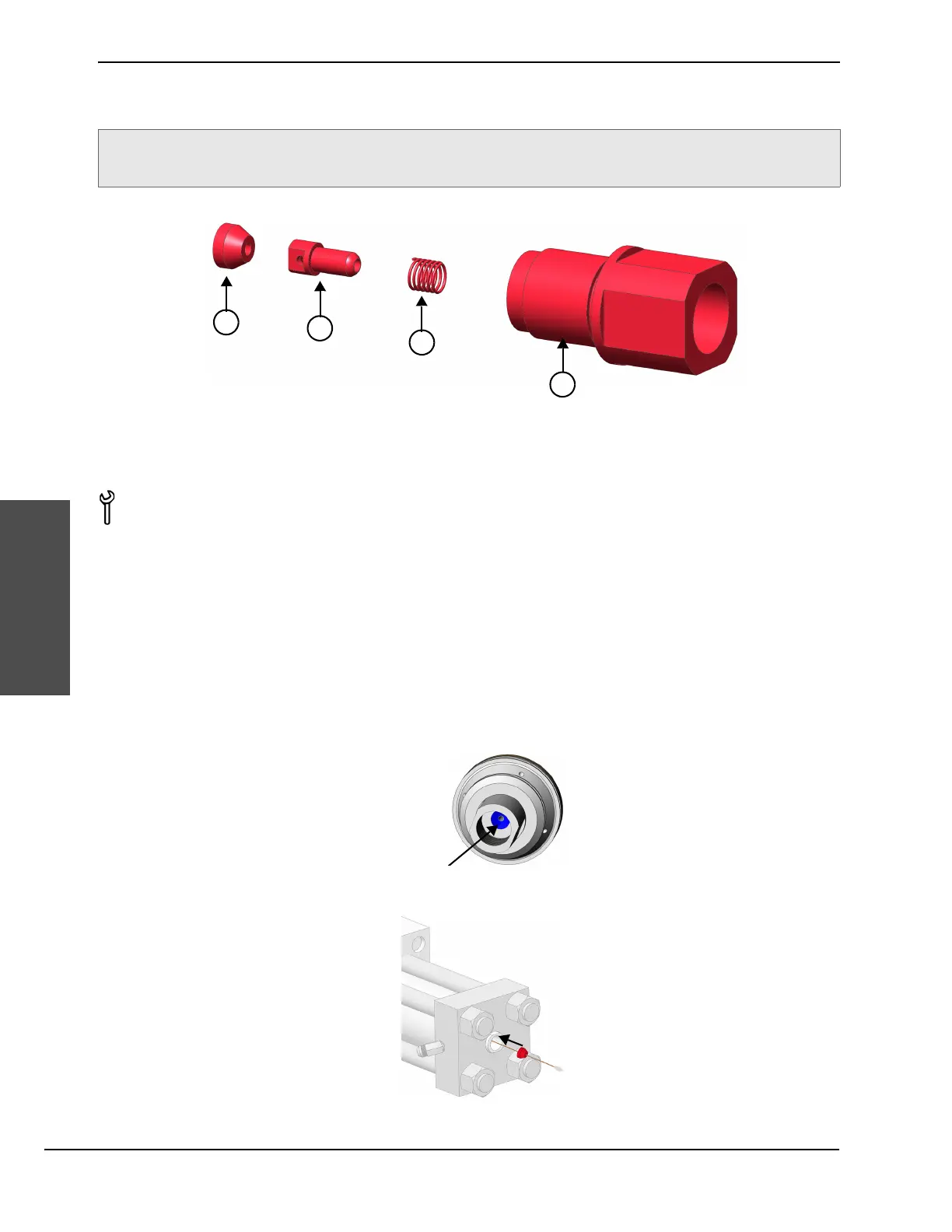

1. Use a cotton-tipped applicator to put high-pressure antiseize lubricant in the recess in the bottom of the

check valve.

2. Use a cotton-tipped applicator to guide the high-pressure poppet seat into the check valve. The wide end of

the poppet seat faces toward the check valve.

3. Push the poppet seat into the high-pressure antiseize lubricant in the check valve.

Repair the high-pressure poppet assemblies every 1,000 hours.

Replace the output adapters every 6,000 hours.

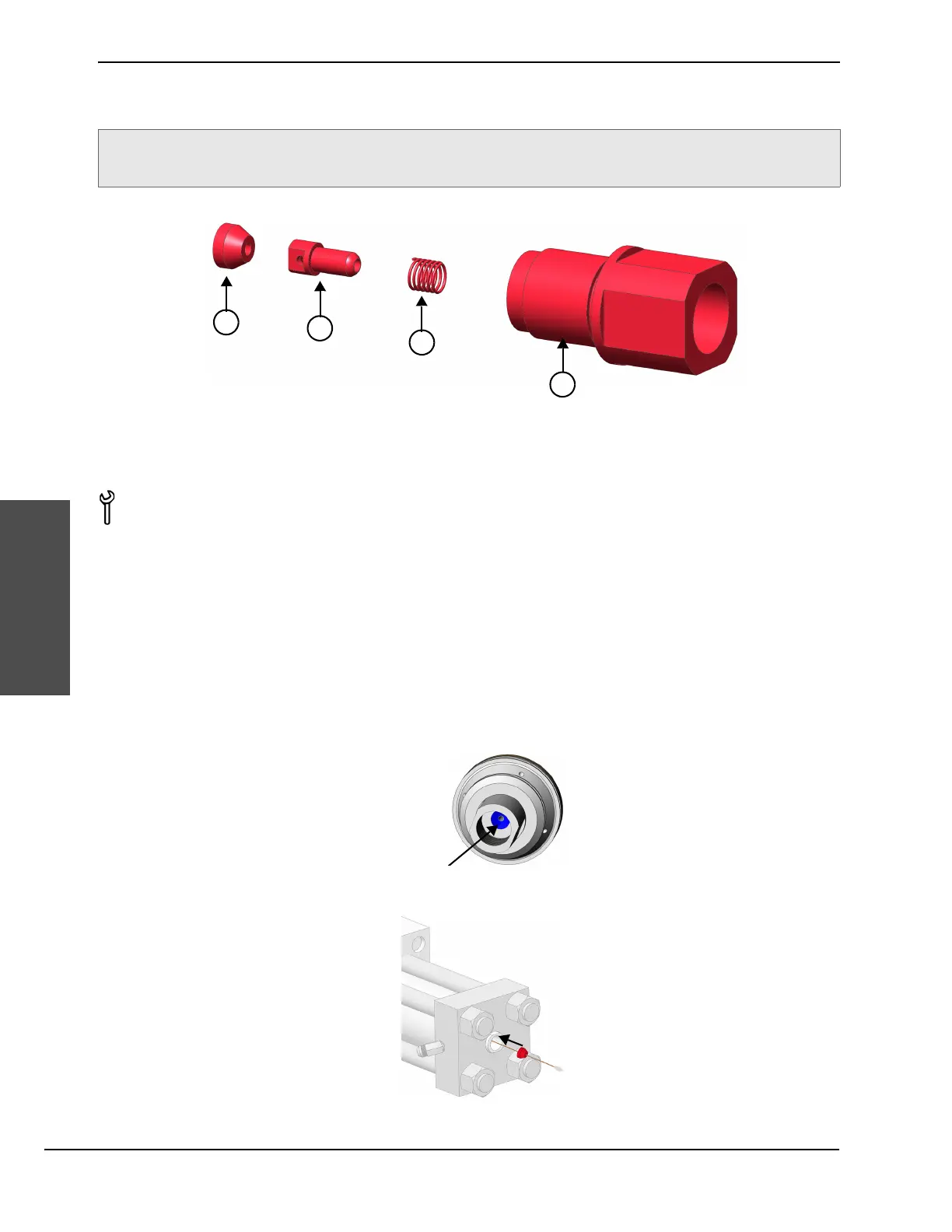

1

1-11010 High-pressure poppet seat

2

1-11014 High-pressure poppet

3

1-11126 High-pressure poppet spring

4

1-11530 Output adapter

1-17437 HyPrecision premium high-pressure seal

repair kit

1-15565 HyPrecision poppet repair kit

(for HyPrecision P-15/P-30/P-50 pumps)

or

1-15568 HyPrecision poppet repair kit

(for HyPrecision P-50S/P-60S/P-75S pumps)

1-11530 Output adapter

High-pressure antiseize lubricant such as Blue

Goop or PURE Goop

1-inch crowfoot wrench or socket

13/16-inch open-ended wrench

Torque wrench

Loading...

Loading...