Maintenance Procedures Every 8 Hours or Daily 8000 SRM 707

Fuel, Oil, or Coolant Leaks, Check

WARNING

All fuels are very flammable and can burn or

cause an explosion. Do not use an open flame

to check the fuel level or to check for leaks in

the fuel system. If there is a leak in the fuel sys-

tem, extra care must be used during the repair.

Donotoperatethelifttruckuntilaleakisre-

paired.

Make a visual check for leaks on and under lift truck.

If possible, find and repair leak at source. Leaks of-

ten indicate a need for repair of damaged or worn

components. Leaks in the LPG fuel system are usu-

ally not visible unless ice is visible. There is, how-

ever, usually a strong odor. Fuel leaks MUST be re-

paired NOW.

Check fuel system for leaks and the condition of

parts. When fuel is added to the lift truck, see the

section How to Add Fuel to the Lift Truck in the

Operating Manual.

Also check the condition of radiator or heater hoses

that are not leaking. Soft or cracked hoses need to be

replaced before a major leak occurs.

Drive Belt

Check drive belts for wear and damage. See Fig-

ure 11.

Intake Manifold Rubber Cap

Check for cracks or dry rot.

Powershift Transmission Oil Temperature

NOTE: Theenginewillstopaftera30-secondwarn-

ing buzzer if transmission oil is over 133

C (271 F) on

S40-65XM lift trucks with protection system.

Check transmission oil level every 250 hours of op-

eration. Heavy-duty or high-temperature operations

will require more frequent checks.

There is an indicator light on the instrument cluster

for the transmission oil temperature. The red light is

on when the key switch is in the START position and

must go off when the engine is running. If the light

is on when the engine is running, the temperature of

the transmission oil is too high. Stop the operation of

lift truck. Make a visual check of transmission and

check transmission oil level.

Powershift Transmission Oil Level

To check the transmission oil, apply parking brake

and, if the lift truck has a direction control lever,

put direction control lever in NEUTRAL (N) posi-

tion. See Figure 10. Run engine for 1 minute to fill

torque converter with oil. Stop engine and check oil

level within 30 seconds. Use the correct oil shown in

the Maintenance Schedule. Keep oil level at FULL

mark on dipstick.

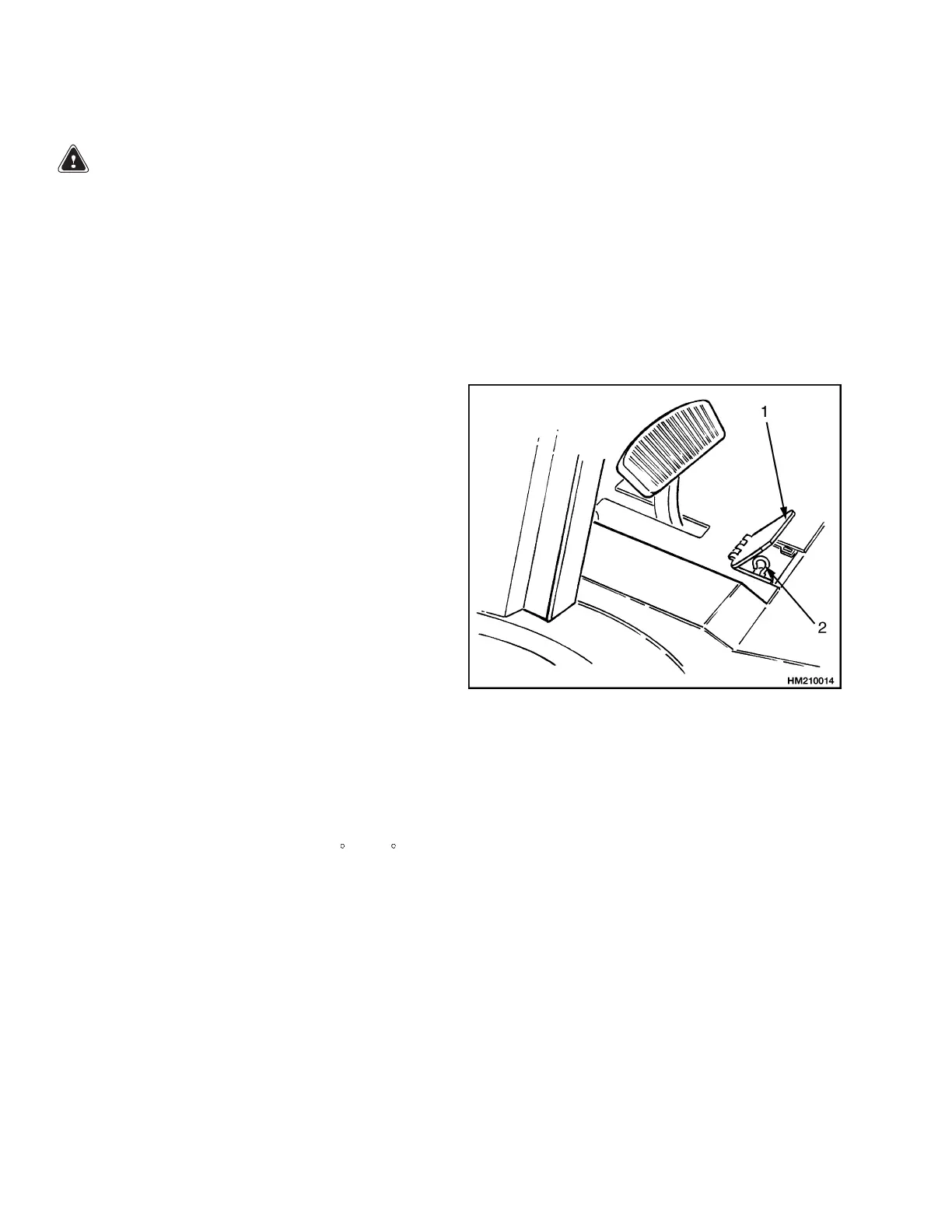

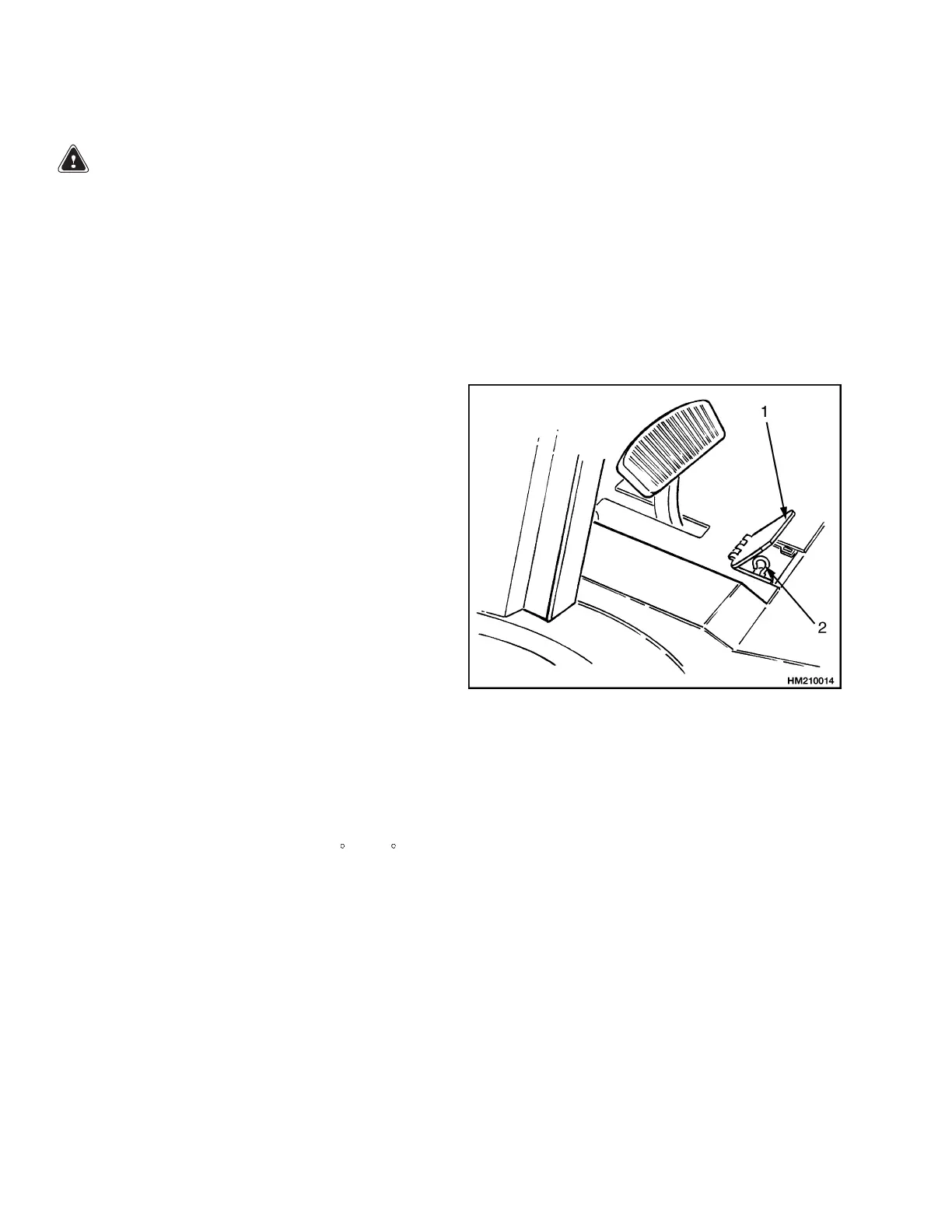

1. ACCESS DOOR

2. DIPSTIC

K FOR TRANSMISSION

Figure 1

0. Transmission Oil Level Check

Engine O

il

Check oi

l level in engine daily. See Figure 11. After

engine h

as stopped, wait 1 minute before checking

oil lev

el. Keep oil at the correct level as indicated on

dipsti

ck. Use the correct oil as shown in the Mainte-

nance S

chedule.

There i

s an indicator light on the instrument cluster

for the

engine oil pressure. The red light is on when

the key

switch is in the START position and must

go off

when the engine is running. If the light is on

when t

he engine is running, the engine oil pressure

is low

. Stop engine and check oil level.

26

Loading...

Loading...