76

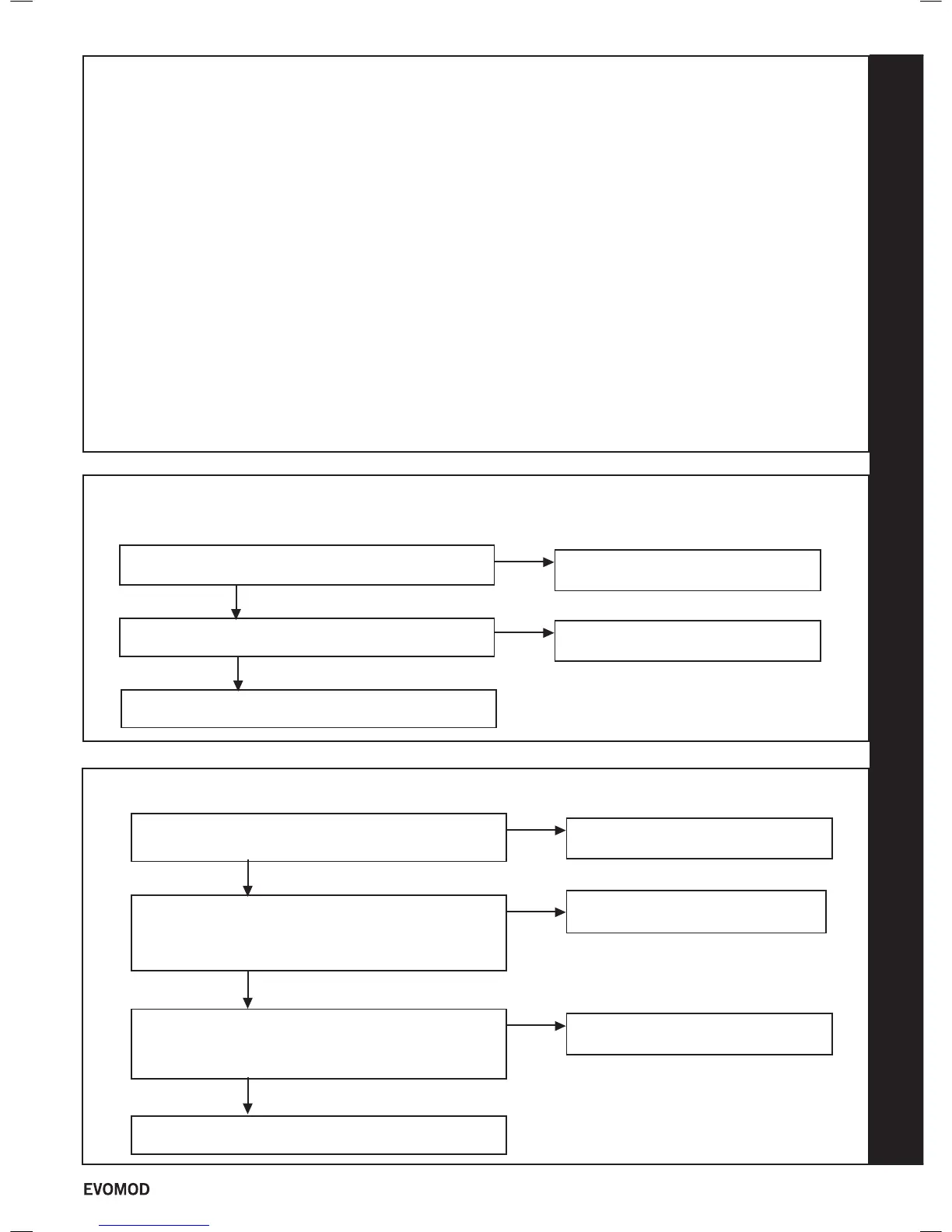

FLAPPER VALVE

Replace Flapper Valve Sensor

no

Disconnect the wiring to the Flapper Valve. With the

fan running is there continuity across the wiring to the

Flapper Valve?

yes

Replace the wiring from the Module

PCB to the Flapper Valve.

no

Does the wiring from the Module PCB to the Flapper

Valve have continuity?

yes

Replace the Module PCB

Check for ue blockage, if clear

replace Flapper Valve

no

Does the Flapper Valve open when the fan is on?

yes

75

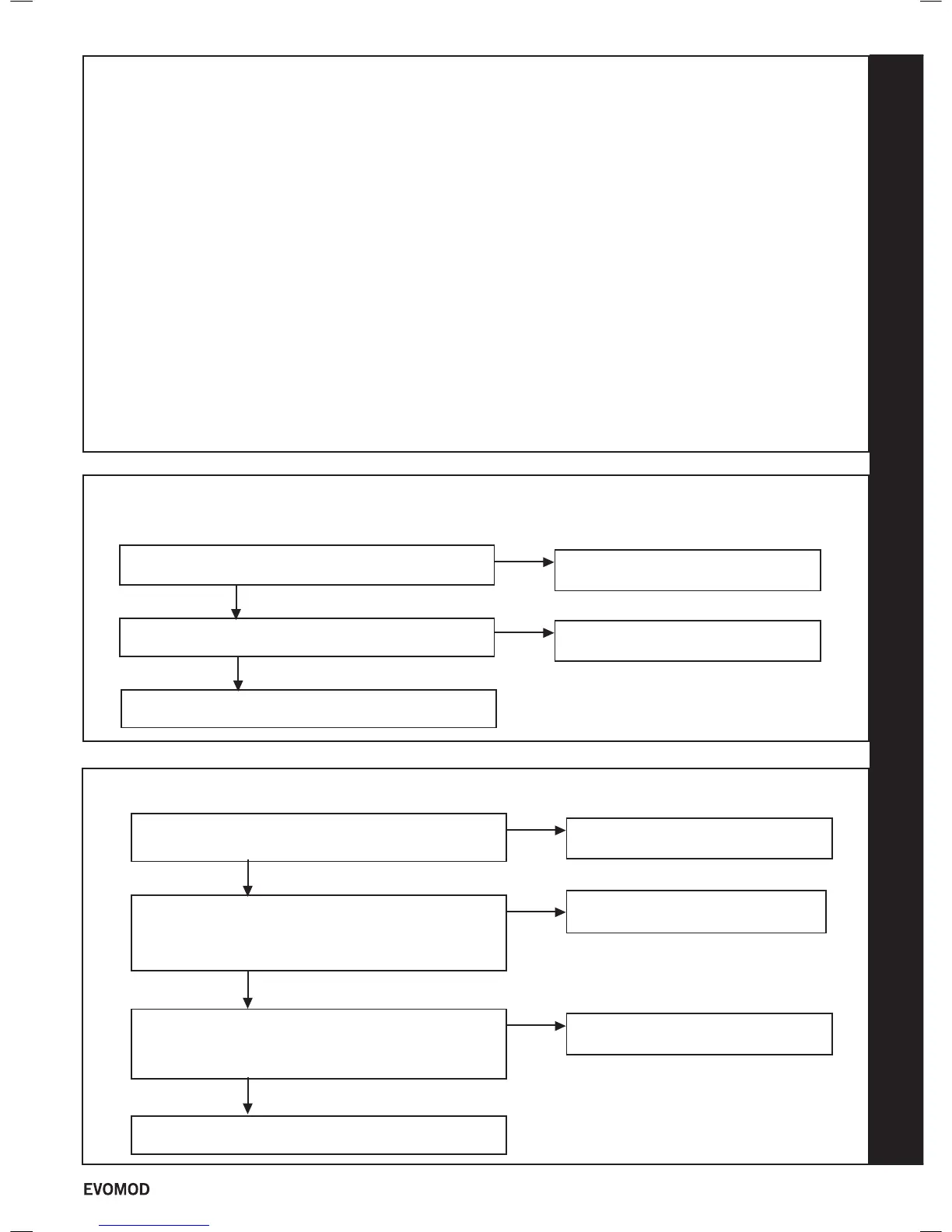

FLOW/RETURN REVERSED

74A

SAFETY THERMOSTAT OPEN

Is the Module Pump connected the correct way?

Reverse Header Pump

no

Is the Header Pump connected the correct way?

yes

Check that the system pipework is correct

yes

Reverse Module Pump

no

The release of the thermostat will require the intervention of a qualied person in the boiler's maintenance; they will have to

remedy the defect responsible for the unusual temperature rise and then carry out a verication (see protocol) of the heat

exchanger before re-engaging the thermostat.

Protocol;

(By following your recommendations for the maintenance to the boiler)

1. Remove the burner door.

2. Check the condition of door gaskets - replace if necessary.

3. Check the condition of the insulation on the door, and the

insulation at the rear of the combustion chamber - replace

if necessary.

4. Check the condition of the burner.

5. Check for fouling of the combustion chamber. If necessary,

clean it (nylon brush and removal of these deposits).

6. Check the condition of the condensate drain. (Clean the

siphon)

7. Check the condition of the ue system.

8. By re-assembling the burner door on to the heat

exchanger, screw the nuts in accordance with the torque to

5N/m.

9. Re-engage the safety thermostat (must be reset at

room temperature which is about 22ºC) and check the

connection (wiring of the thermostat).

10. Before restarting of the boiler, check the water pressure in

the boiler.

11. After restarting, control the level of combustion (CO

2

measurement) by verifying the correct adjustment of the

gas valve in relation to the type of gas.

53

- Installation & Servicing

Loading...

Loading...