7

8

14

INSTALLER

USER

MAINTENANCE TECHNICIAN

TECHNICAL DATA

e climate regulator incorporated into the remote panels enables

the system ow temperature to be adjusted to the actual needs

of the room being heated, in order to obtain the desired room

temperature with extreme precision and therefore with evident

saving in running costs. e Mini CRD and CAR

V2

are fed di-

rectly by the boiler by means of the same 2 wires used for the

transmission of data between the boiler and devices.

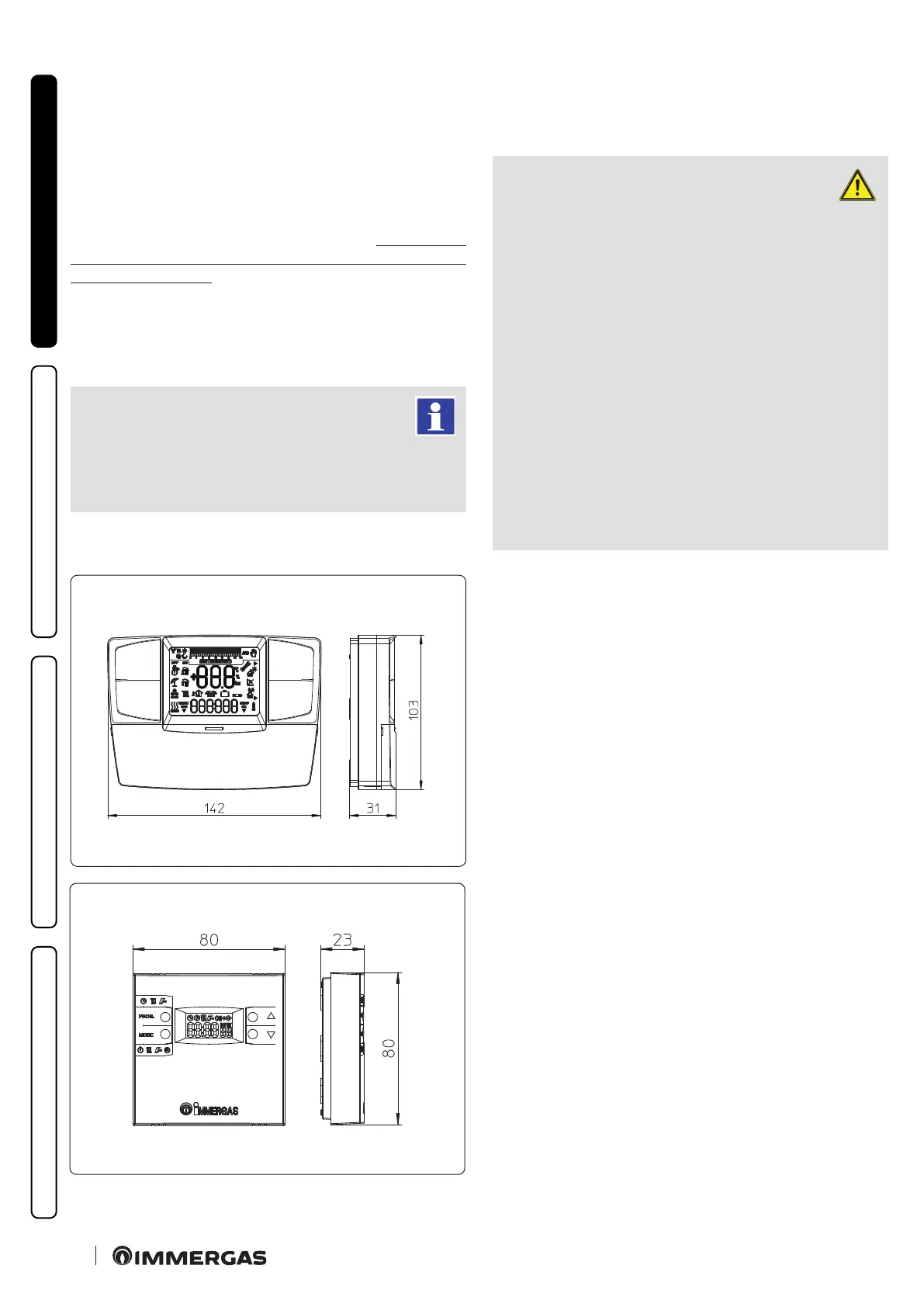

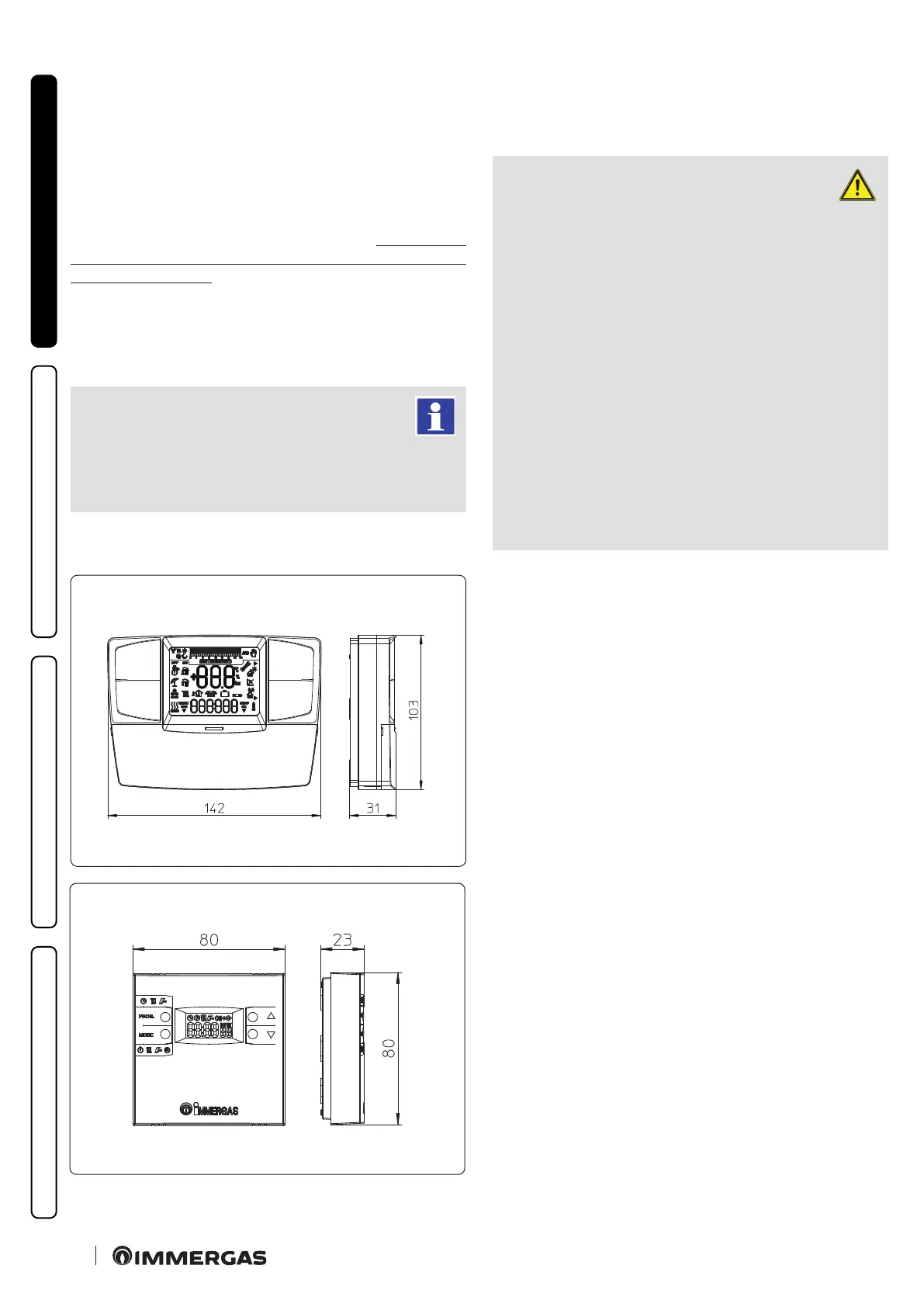

Digital Remote Mini-Control or CAR

V2

or On/O chrono-

thermostat electrical connections (Optional). e operations

described below must be performed aer having removed the vol-

tage from the appliance. Any room chrono-thermostats or remote

controls must be connected to the 40 and 41 terminal blocks,

eliminating the X40 jumper (Fig. 36). Make sure that the On/O

thermostat contact is of the “clean” type, i.e. independent of the

mains voltage, otherwise the P.C.B. would be damaged. e boiler

can only be connected to one device at a time.

If the Mini CRD or CAR

V2

remote control is used,

arrange two separate lines in compliance with current

regulations regarding electrical systems. No boiler

pipes must ever be used to earth the electric system or

telephone lines. Ensure elimination of this risk before making

the boiler electrical connections.

1.9 IMMERGAS FLUE SYSTEMS.

Immergas supplies various solutions separately from the boilers

regarding the installation of air intake terminals and ue exhaust,

which are fundamental for boiler operation.

ATTENTION:

the boiler must be installed exclusively

with an original Immergas “Blue Ran-

ge” inspectionable air intake system and ue

gas extraction system made of plastic, with the

exception of the C6 conguration, as required

by the regulations in force and by the product’s

approval.

is ue can be identied by an identication

mark and special distinctive marking bearing

the note "only for condensation boilers".

e ue exhaust pipes must not be in contact

with or be near to ammable materials. Mo-

reover, they must not pass through buildings

or walls made of ammable material.

• Resistance factors and equivalent lengths.

Each ue component has a Resistance Factor based on exper-

imental tests and specied in the table below. e Resistance

Factor for individual components is independent from the type

of boiler on which it is installed and has a dimensionless size. It

is however, conditioned by the temperature of the uids that pass

through the pipe and therefore, varies according to applications

for air intake or ue exhaust. Each single component has a resist-

ance corresponding to a certain length in metres of pipe of the

same diameter; the so-called equivalent length, can be obtained

from the ratio between the relative Resistance Factors.

All boilers have an experimentally obtainable maximum Re-

sistance Factor equal to 100.

e maximum Resistance Factor allowed corresponds to the

resistance encountered with the maximum allowed pipe length

for each type of Terminal Kit. is information allows calcula-

tions to be made to verify the possibility of setting up various

ue congurations.

Note: to dimension the ue ducting using commercial compo-

nents, refer to the table of combustion parameters (Paragraph 4.2).

Loading...

Loading...