40

INSTALLER

USER

MAINTENANCE TECHNICIAN

TECHNICAL DATA

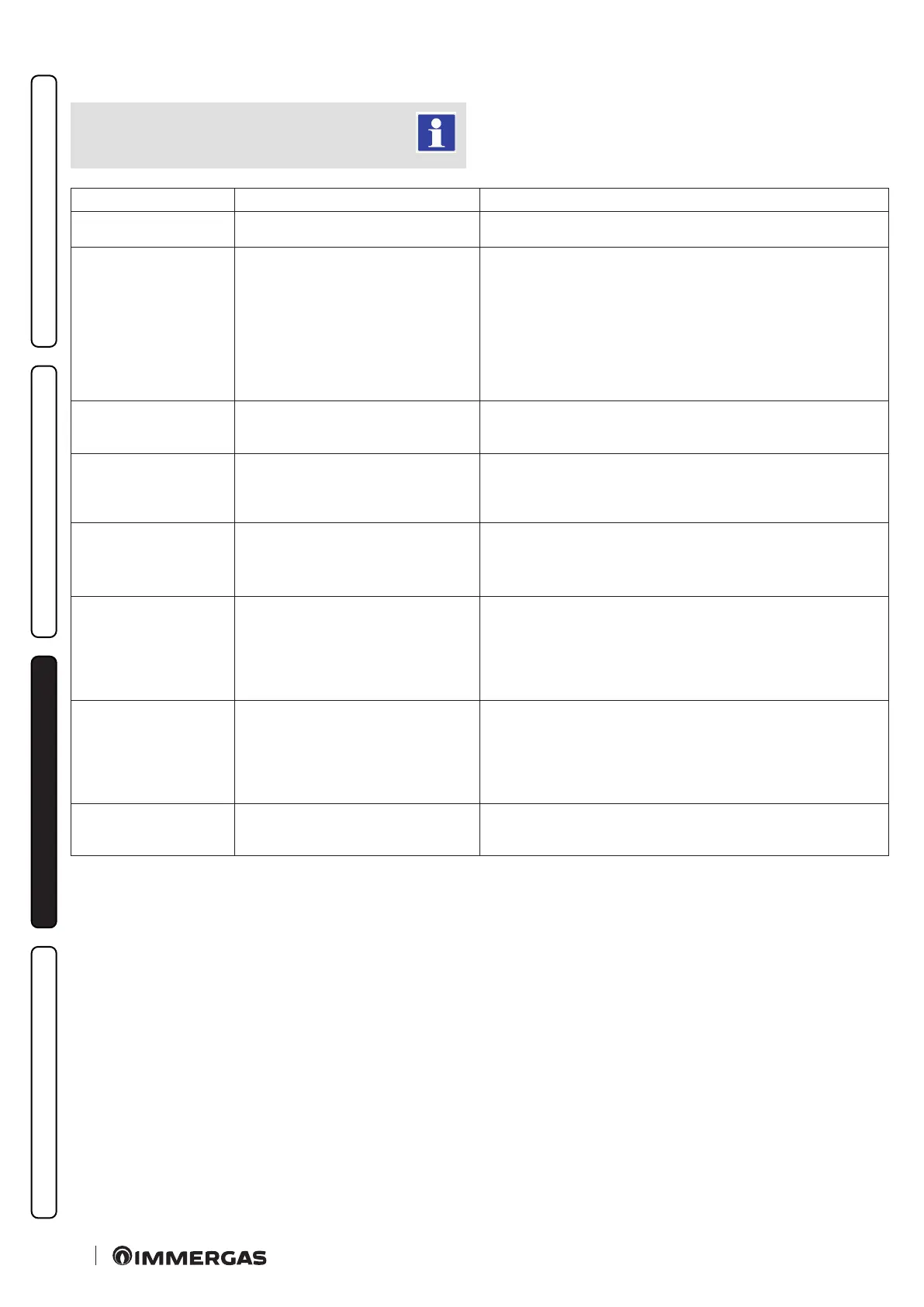

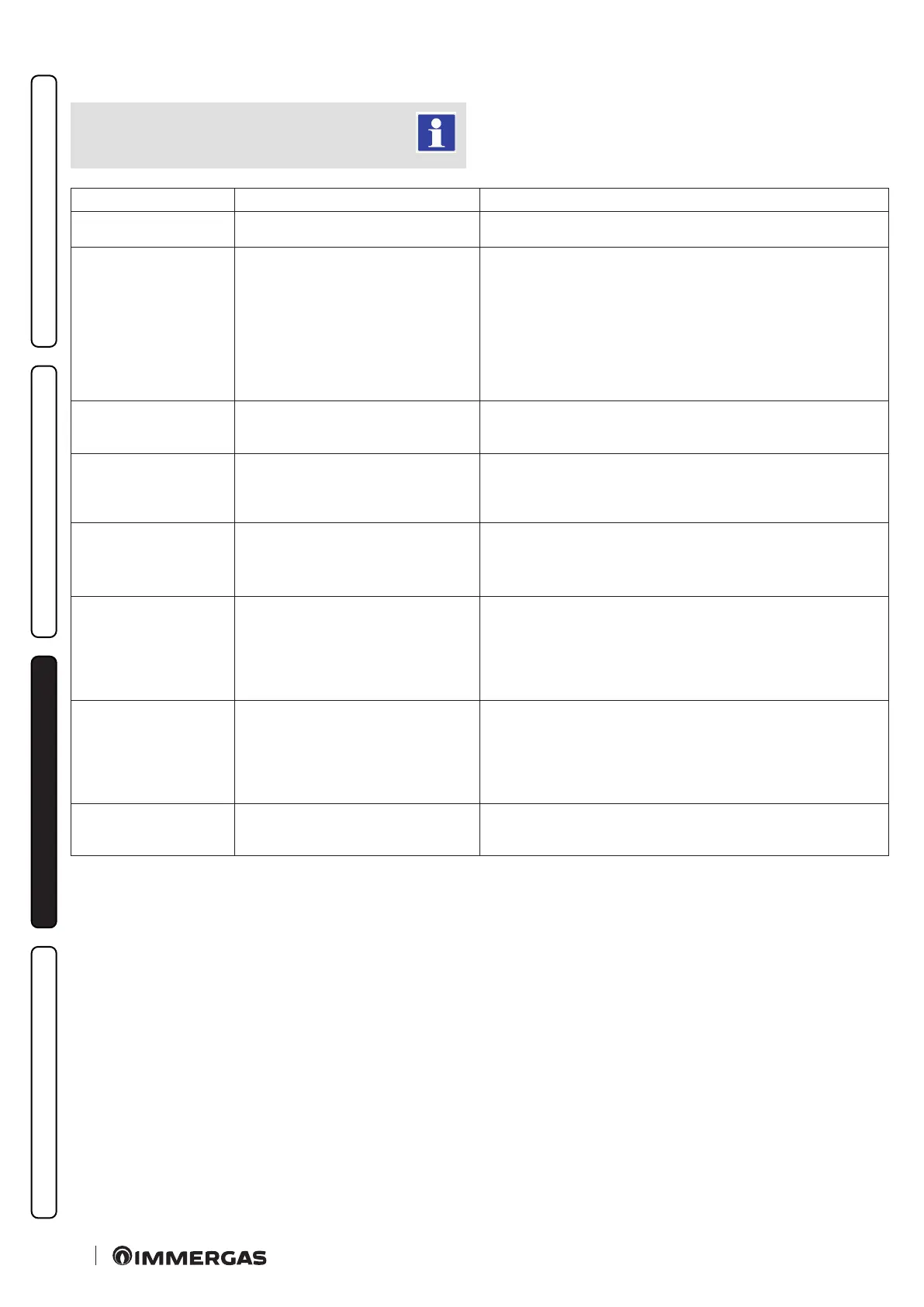

Trouble Possible causes Solutions

Smell of gas

Caused by leakage from gas circuit pipe-

lines

Check sealing eciency of gas intake circuit.

e fan works but ignition

discharge does not occur

on the burner ramp

e fan may start but the safety air pres-

sure switch does not switch the contact

over.

Make sure:

1) the intake-exhaust duct is not too long (over allowed length).

2) the intake-exhaust pipe is not partially blocked (on the exhaust or

intake side).

3) the diaphragm of the fume exhaust is adequate for the length of the

intake-exhaust duct.

4) the sealed chamber is kept in good conditions.

5) the fan power supply voltage is not less than 196 V.

Irregular combustion (red

or yellow ame).

Can be caused by: dirty burner, clogged

lamellar pack, intake - exhaust terminal

not installed properly.

Clean the above components and ensure correct installation of the

terminal.

Frequent activation of

the temperature overload

thermostat

It can depend on reduced water pres-

sure in the boiler, little circulation in the

heating system, the blocked pump or an

anomaly of the boiler P.C.B.

- Check on the pressure gauge that the system pressure is within established

limits.

- Check that radiator valves are not all closed.

Abnormal noises in the

system

Air in the system.

- Check opening of the special air vent valve cap (Fig. 33).

- Make sure the system pressure and expansion vessel factory-set pressure

values are within the set limits; the factory-set value for the expansion

vessel must be 1.0 bar, and system pressure between 1 and 1.2 bar.

Ignition block

In the event of request of room central

heating or domestic hot water produc-

tion, the boiler does not switch on within

the preset time. Upon appliance commis-

sioning or aer extended downtime, it

may be necessary to eliminate the block.

Press the Reset button (1).

Low water ow

Can be caused by on limescale deposits

(calcium and magnesium)

Contact a qualied technician for descaling e.g. Aer-Sales Technical

Service. Descaling must be carried out on the domestic hot water side

of the bithermal heat exchanger in accordance with good practice. To

preserve integrity and eciency of the heat exchanger, a non corrosive

descaler must be used. Cleaning must be carried out without the use of

tools which can damage the heat exchanger.

Presence of condensation

on the boiler.

It can be determined

by functioning at boiler temperatures

that are excessively low.

In this case, make the

boiler run at higher temperatures.

3.6 POSSIBLE PROBLEMS AND THEIR CAUSES.

Maintenance interventions must be carried out by

an authorised company (e.g. Authorised Aer-Sales

Technical Assistance Service).

Loading...

Loading...