31 - IE

INSTALLERUSER

MAINTENANCE TECHNICIAN

3.9 "CHIMNEY SWEEP FUNCTION" F2.

If this function is activated it takes boiler

functioning to the adjustable power of the central

heating selector switch.

In this state all adjustments are excluded and only

the safety thermostat and the limit thermostat

remain active. To activate the chimney sweep

press the Reset button "C" for a time between 8

and 15 seconds in absence of domestic hot water

and heating requests. Its activation is signalled by

the relative symbol (22 Fig. 2-1). is function

allows the technician to check the combustion

parameters. After the checks deactivate the

function, switching the boiler o and then on

again using the Stand-by button.

3.10 PUMP ANTIBLOCK FUNCTION.

e boiler has a function that starts the pump at

least once every 24 hours for the duration of 30

seconds in order to reduce the risk of the pump

becoming blocked due to prolonged inactivity.

3.11 THREEWAY ANTIBLOCK

FUNCTION.

Both in “domestic hot water” and in “domestic

hot water-central heating” phase the boiler is

equipped with a function that starts the three-

way motorised group 24 hours aer it was last

in operation, running it for a full cycle so as to

reduce the risk of the three-way group becoming

blocked due to prolonged inactivity.

3.12 RADIATORS ANTIFREEZE

FUNCTION.

If the system return water temperature is near

to freezing, the boiler starts up until reaching a

safe temperature.

3.13 P.C.B. PERIODICAL SELFCHECK.

During functioning in heating mode or with

boiler in standby, the function activates every 18

hours aer the last boiler check/power supply. In

case of functioning in domestic hot water mode

the self-check starts within 10 minutes aer the

end of the withdrawing in progress, for duration

of approx. 10 seconds.

N.B.: during self-check, the boiler remains o.

3.14 AUTOMATIC VENT FUNCTION.

In the case of new heating systems and in

particular mode for floor systems, it is very

important that dearation is performed correctly.

To activate the “F8” function, press buttons “A

and B” at the same time (Fig. 2-1) for 5 seconds

with boiler in stand-by. e function consists in

the cyclic activation of the pump (100 s ON, 20

s OFF) and the 3-way valve (120 s domestic hot

water, 120 s central heating). e function ends

aer 18 hours or by switching the boiler on using

the ignition button “

”.

3.15 SOLAR PANELS COUPLING

FUNCTION.

e boiler is set-up to receive pre-heated water

from a system of solar panels up to a maximum

temperature of 65 °C. In the case of use with

higher temperatures it is recommended to install

a mixing valve on the hydraulic circuit upstream

from the boiler. Set the “P 71” function on “P

71.1” (Par. 3.8).

When the boiler inlet water is at a temperature

that is equal or greater with respect to that set by

the domestic hot water selector switch “SET”, the

boiler does not switch on.

3.16 YEARLY CONTROL AND

MAINTENANCE OF THE

APPLIANCE.

e following checks and maintenance should

be performed at least once a year.

- Clean the ue side of the heat exchanger.

- Clean the main burner.

- Check correct ignition and functioning.

- Ensure correct calibration of the burner in

domestic water and heating phases.

- Check correct functioning of appliance control

and adjustment devices and in particular:

- the intervention of main electrical switch on

the boiler;

- system control thermostat intervention;

- domestic hot water control thermostat

intervention.

- Check sealing eciency of gas circuit and the

internal system.

- Check intervention of the device against no gas

ionization ame control:

- check that the relative intervention time is

less than 10 seconds.

- Visually check for water leaks or oxidation

from/on connections and traces of condensate

residues inside the sealed chamber.

- Check, by means of the condensate drain cap,

that there are no residues of material blocking

the ow of condensate.

- Check contents of the condensate drain trap.

- Visually check that the water safety drain valve

is not blocked.

- Check that, aer discharging system pressure

and bringing it to zero (read on boiler

manometer), the expansion vessel charge is at

1.0 bar.

- Check that the system static pressure (with

system cold and aer relling the system by

means of the ller cock) is between 1 and 1.2

bar.

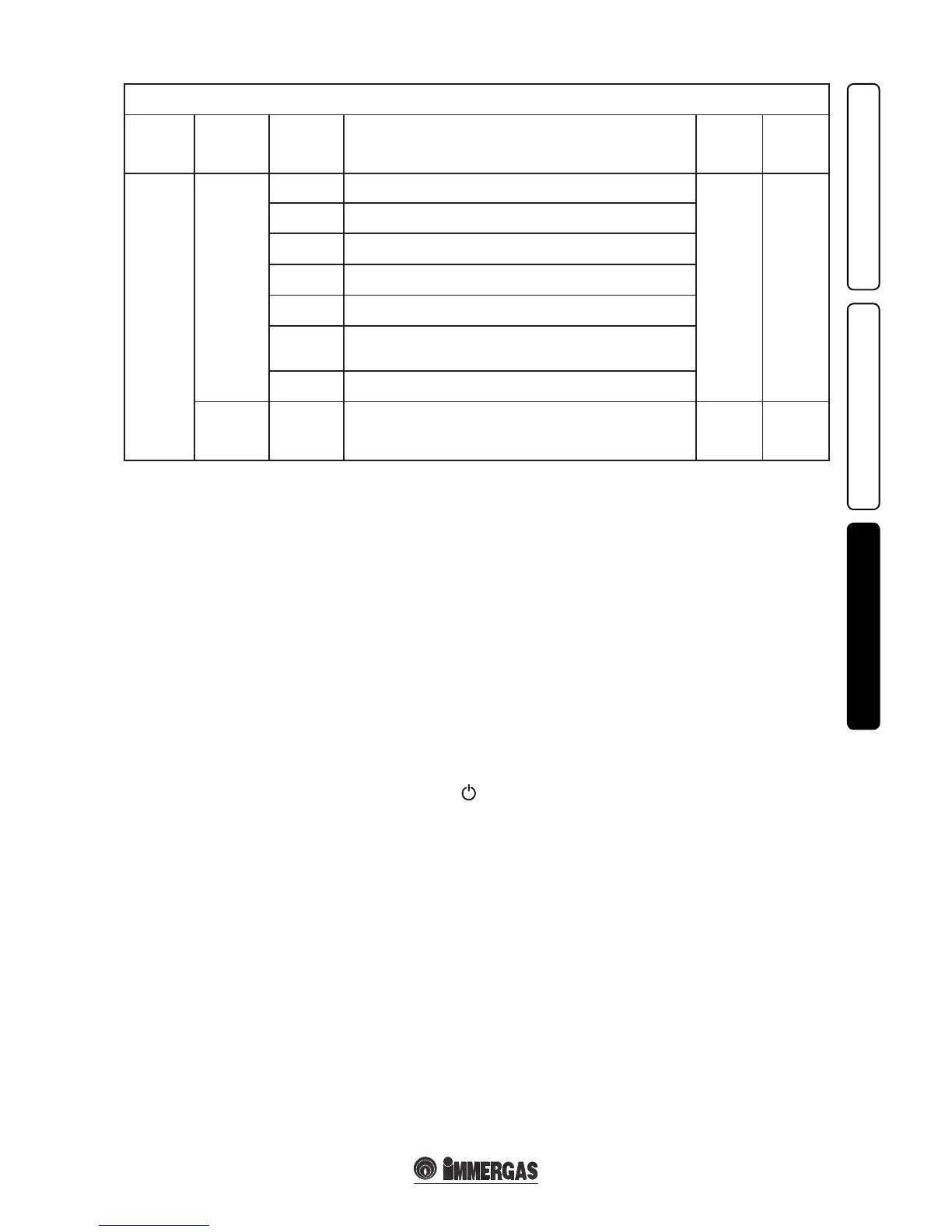

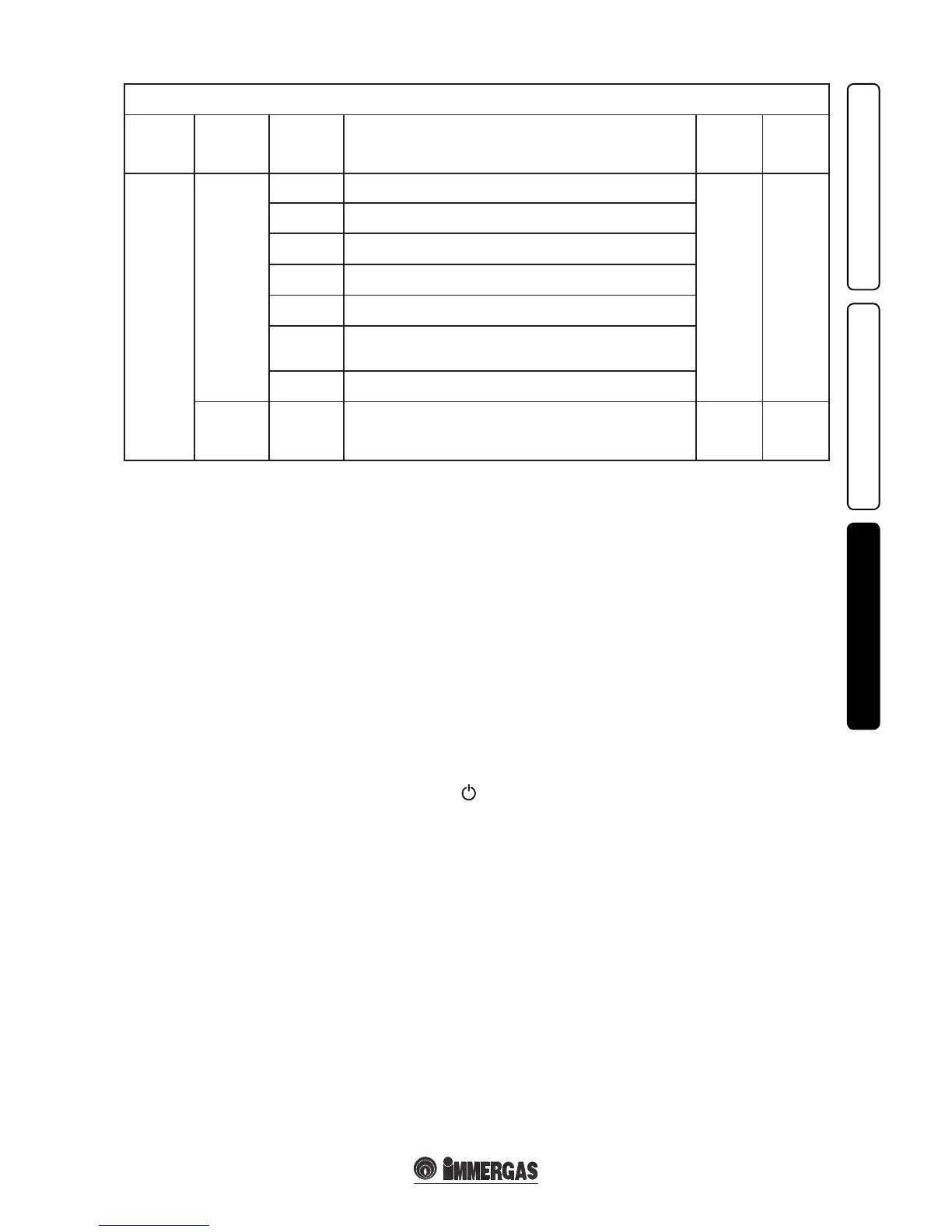

M5 menu

(password must be entered)

1

st

Level 2

nd

Level Options Description

Default

value

Value

set

by the

technician

RELE3

(optional)

RELE3-0 Relay 3 not used.

RELE3-0

RELE3-1

Check the storage tank recirculation pump.

(not usable on this model).

RELE3-2

e relay signals the intervention of boiler block ( Can be coupled to an

external signalling device, not supplied).

RELE3-3

e relay signals that the boiler is on in heating phase.

(Can be coupled with an external pump, not supplied).

RELE3-4

Controls the opening of an external gas valve in concomitance with an

ignition request of the boiler burner.

RELE3-5

Operation with heat pump. Coupled to the 2-5 operation of relay 2 and

an interface (not supplied) allows the management of the boiler coupled

to a heat pump.

RELE3-6

In case the boiler pump needs to be replaced with a traditional pump at

xed speed it is necessary to connect the new pump to the relay board.

P76

-15°C ÷

+14°C

CE

With S34 = On. If the reading of the external probe is not correct it is possible

to correct it in order to compensate any environmental factors.

With S34 = O and system supervisor connected, set the parameter to

maximum until the CE value appears.

0°C

Loading...

Loading...