17

2.4 Finishing work

- Straighten the stroke drive.

- Once the bracing bubble is relieved, remove the cutter drive with hose and push rod

from the pipe

- Check pressure monitoring (the light must not flash for approx. 40 seconds)

- Insert the cutter drive into the auxiliary tube

- Allow the air motor with the cutter tool to run for another approx. 20 seconds in order to

blow out the residual water from the cutter motor

- Switch off the air motor and spray a small amount of biodegradable oil

(Ballistol – www.ballistol-shop.de) into the exhaust openings of the air motor, then

switch the air motor back on for just a moment (approx. 5 seconds)

- For longer periods of rest, remove the cutter motor and store it in a dry place

- Switch the compressor OFF (prior to switching the air motor OFF) so that the cutter is

completely depressurized

- Once the cutter motor has come to a stop, switch the air motor OFF (do not forget this

step, as otherwise there is a risk of injury during the next start-up)

- Clean cutter drive with camera, hose packet and push rod.

- Unscrew the push rod.

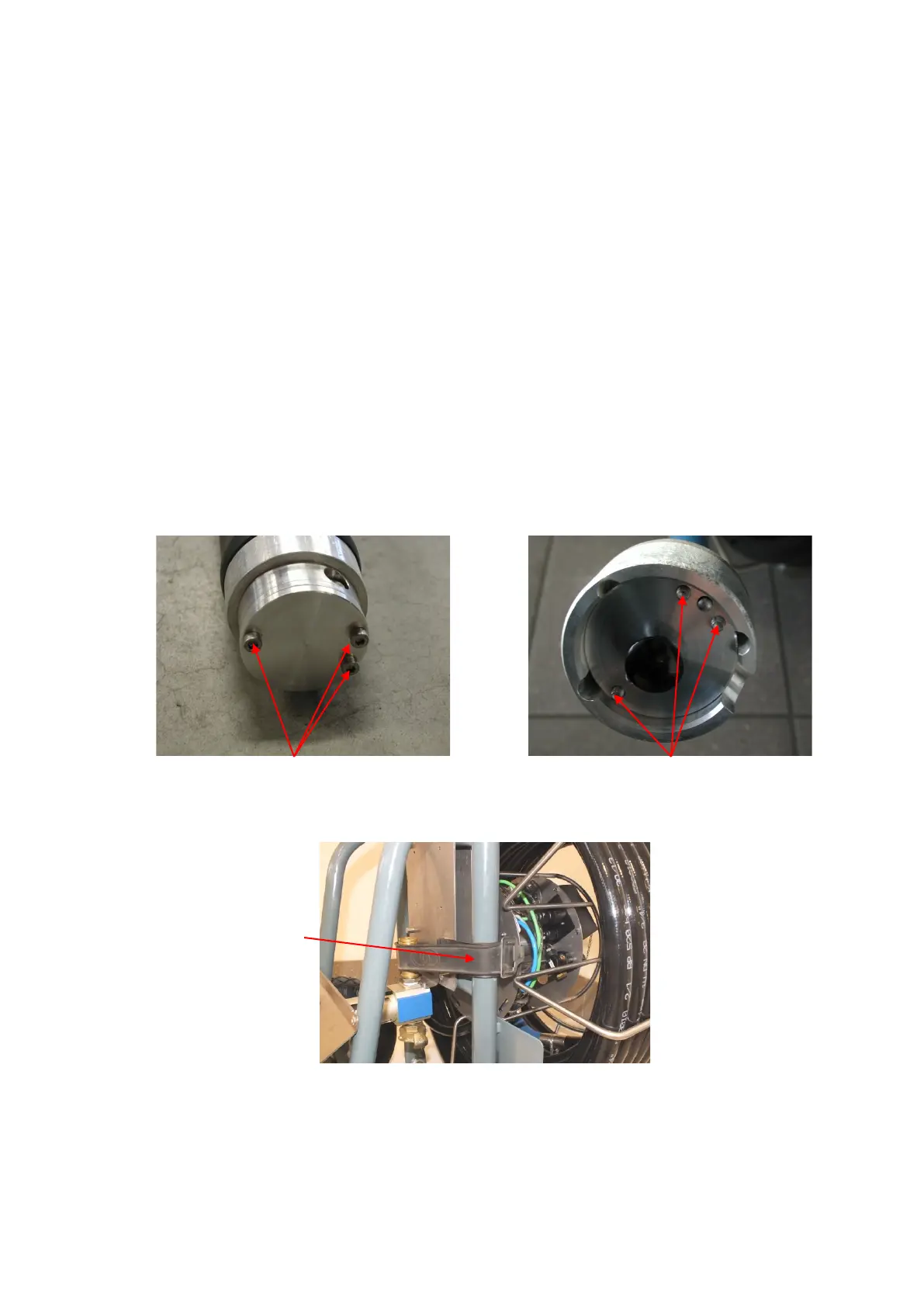

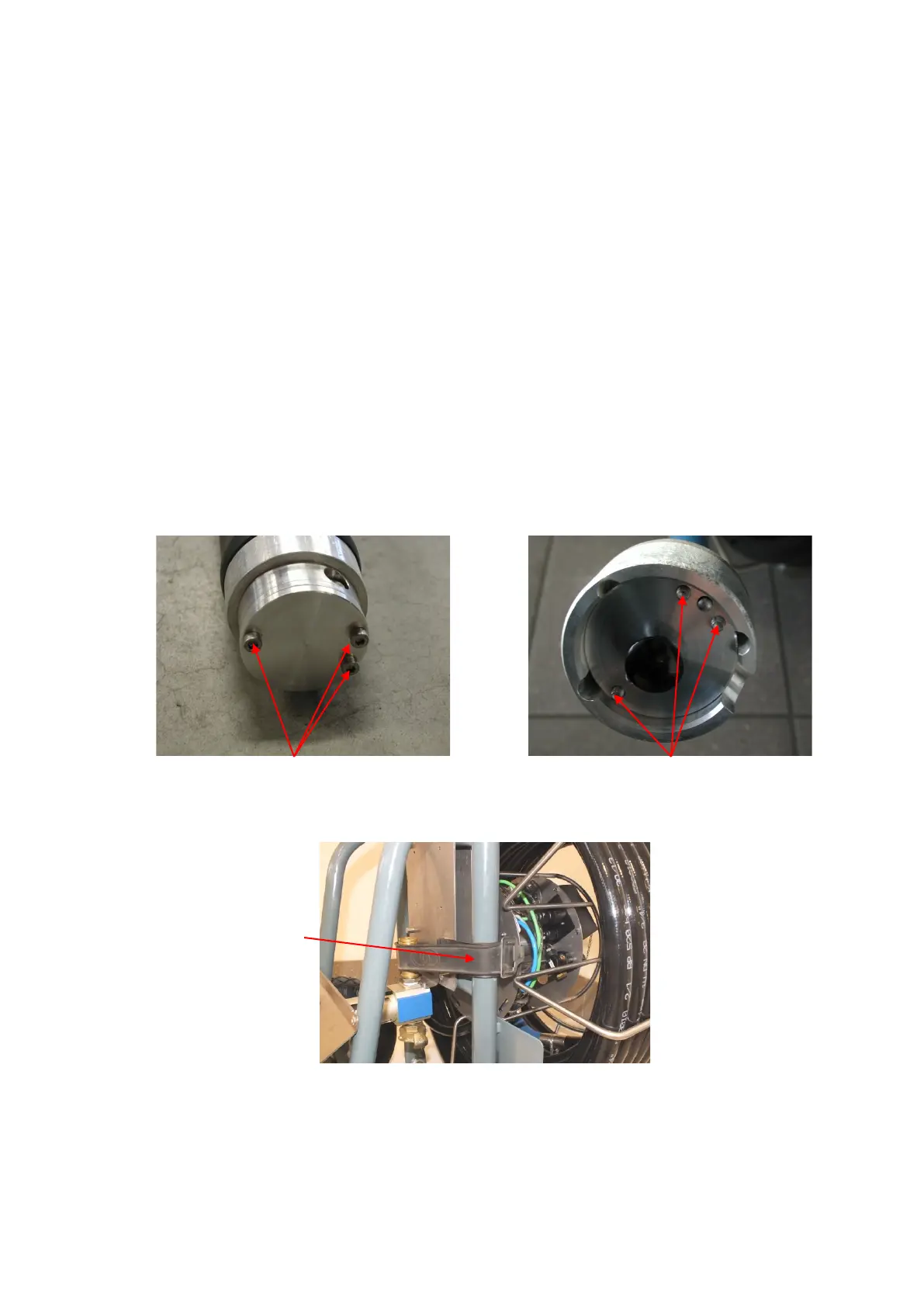

- Unscrew the cutter drive from the hose package (3 screws M5x45) and the couplings

from the cutter drive, secure the hose package with covering plates.

- Reel up the hose package and secure it with a rubber band against slipping, use

another rubber band to secure the reel against turning.

- Store rack and cutter drive well protected in the vehicle; do not buckle the bracing and

stroke bubble of the cutter drive

- Pack the control unit, power supply unit and accessories in the accessories case

- Protect the complete rack against being damage during transport

Loading...

Loading...