27

4.4 Checking the pressure reducer

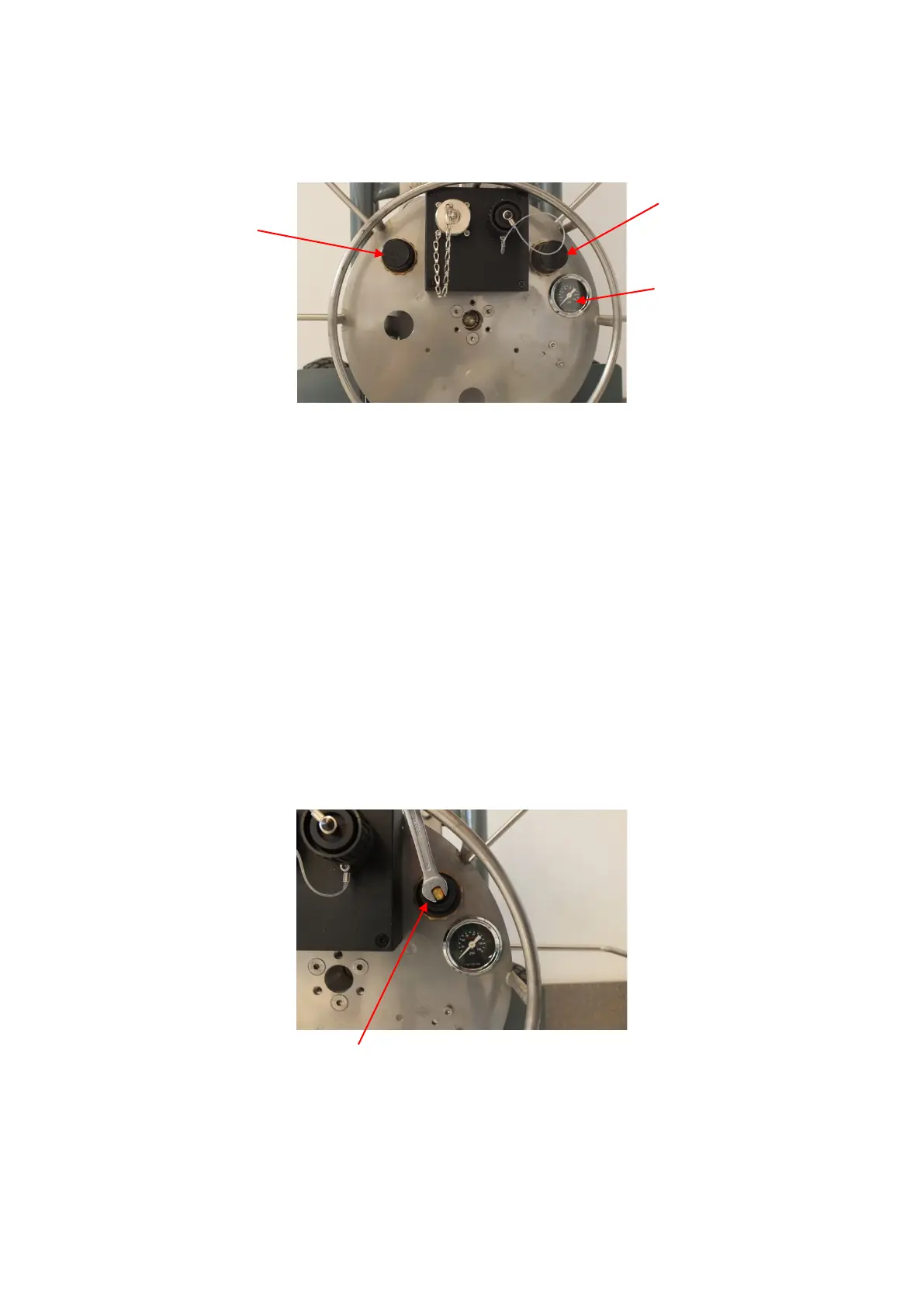

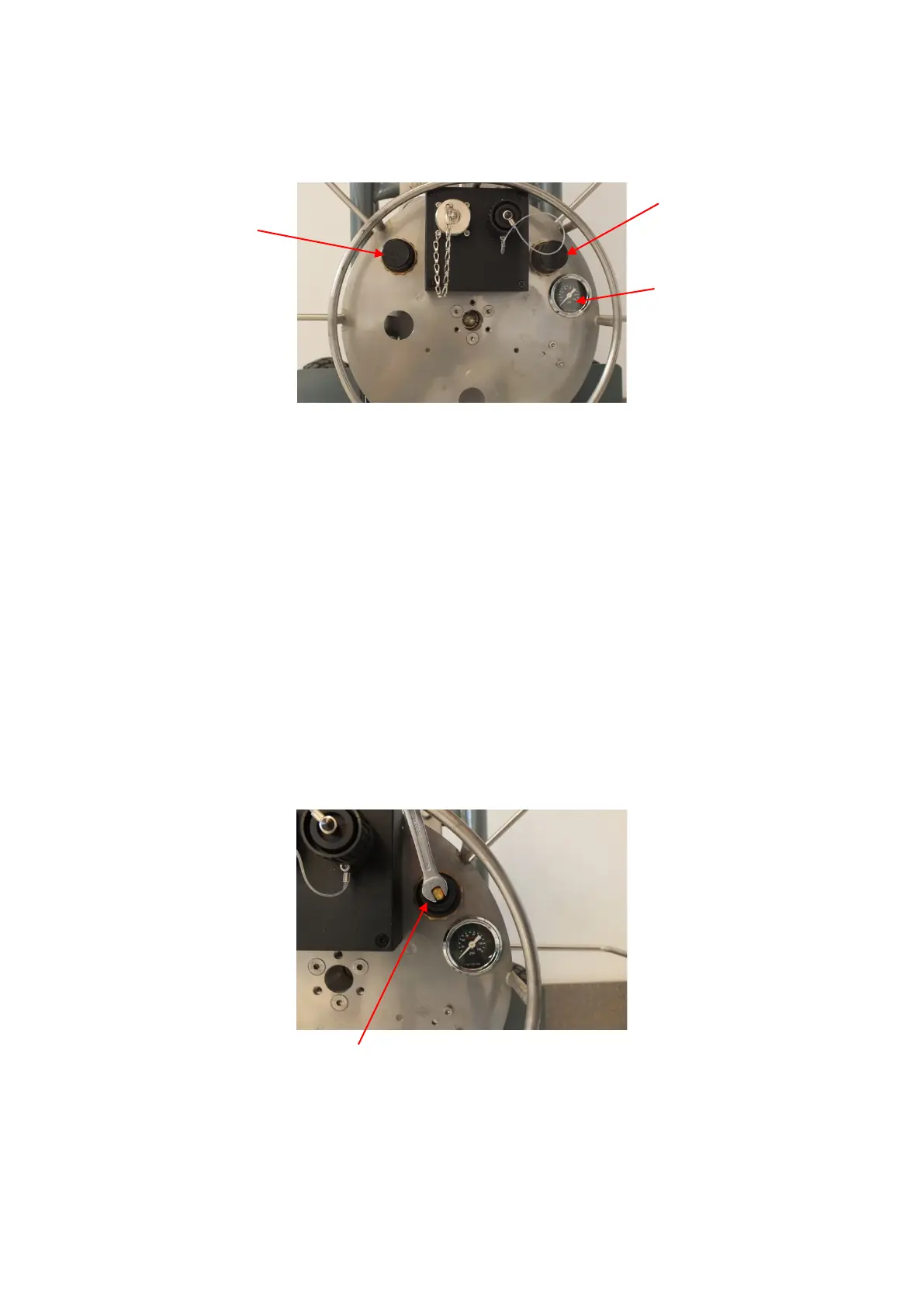

4.4.1 Checking the pressure reducer for the stroke drive

The stroke pressure is indicated by a pressure gauge. Actuate to full stroke and read the

pressure in the pressure gauge. The adjusted pressure must be 6 bar.

Otherwise pry the cap off the pressure reducer 1 (DM1) with a screwdriver and keep turning

the nut on the pressure reducer with an NW 6 open end spanner, until the pressure gauge

indicates a pressure of 6 bar Turning clockwise increases the pressure. Turning counter-

clockwise reduces the pressure.

Once the pressure is correctly adjusted, check the setting several times. Actuate and relieve

several times.

Seal the adjusting screw, place the cap on the pressure reducer 1 and press it on to snap

into place.

If an adjustment is not possible, the cutter should be stopped immediately and the pressure

reducer must be renewed. (Overpressure may burst the stroke bubble).

You can replace a defective pressure reducer yourself. In this respect refer to point 0 .

Loading...

Loading...