E020 - Replace end position dampers

Orientation

Besides the software end positions and the emergency stop switches, the end

position dampers are another safety device to protect the machine from damage.

Their job is to absorb the impact force to the spindle bearings.

Therefore, regular inspection of the end position dampers for damage is necessary

to prevent damage to the spindle and its bearings.

Position tool carrier such as to allow easy access to the specific end position

damper.

Procedure

1.

Power off the machine and secure it against power on.

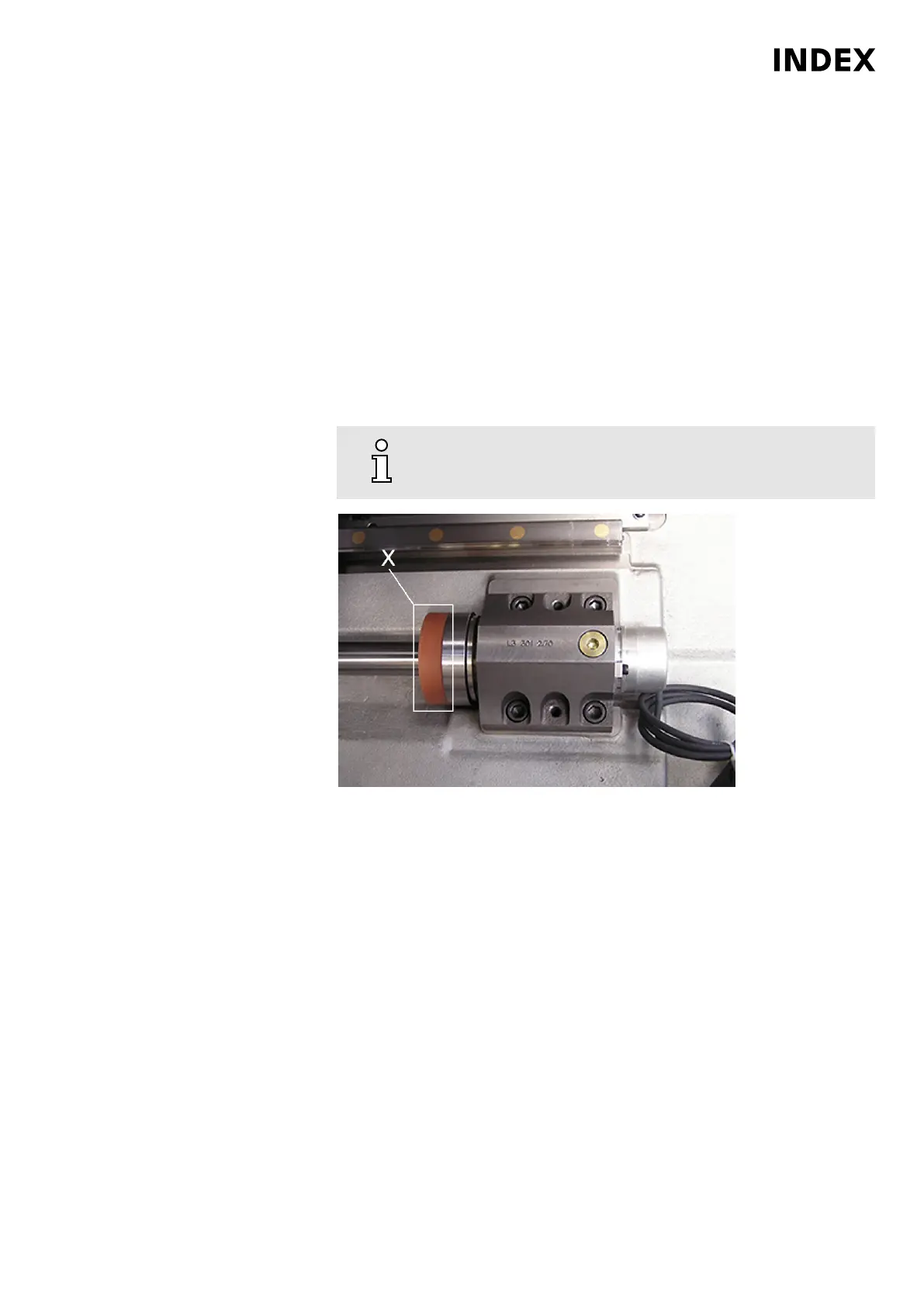

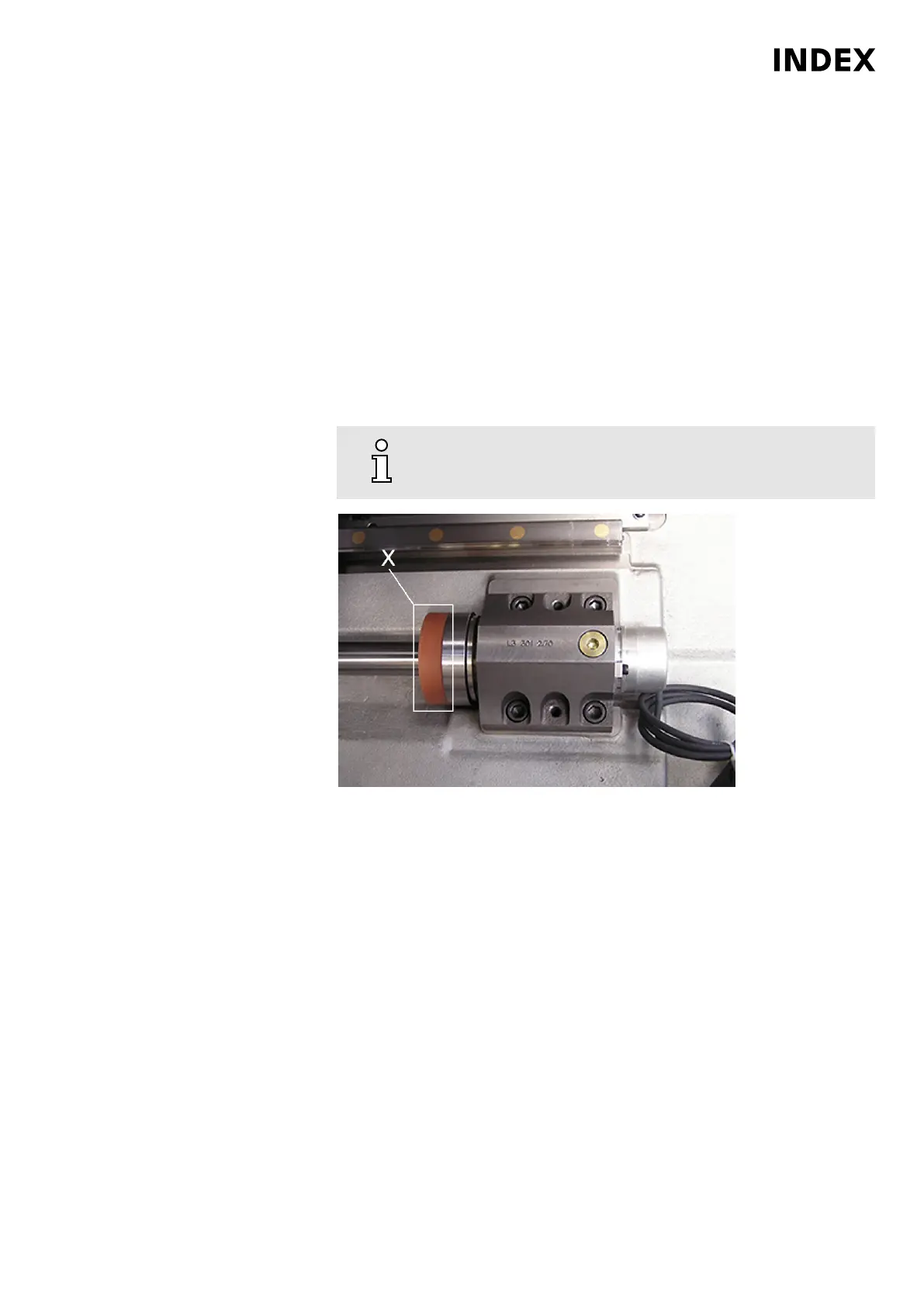

Example: End position damper (X), G200

Remove screws on the end position damper (red/orange).

2. Replace damper. The damper has a slit on one side and can be slid over the

ballscrew by rotating it.

3. Insert new dampers and secure with the screws. Do not tighten the screws with

the rated torque. It is sufficient to tighten the screws by hand.

Maintenance Summary - 8.000 Operating hours

115

Maintenance Instructions

C200

LP1702.10021 - 05.06.2019

Loading...

Loading...