5.

Only one insert screen may be present in the chip conveyor

during operation.

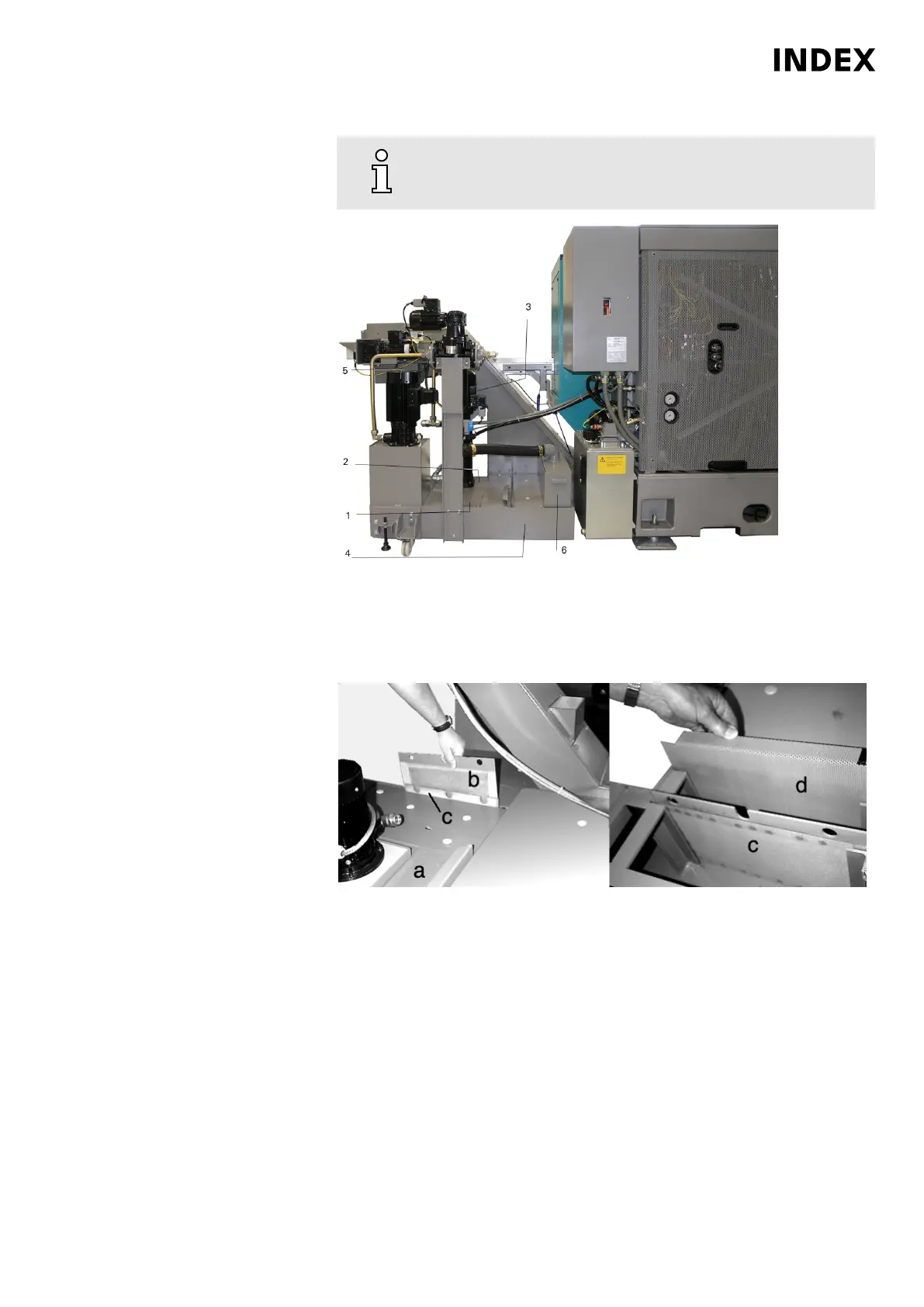

Example: Chip conveyor C100/C200

1

Cover sheet

2 Pump box

3 Booster pump

4 Chip conveyor with cooling lubricant tank

5 End supply pump

6 Sludge tank

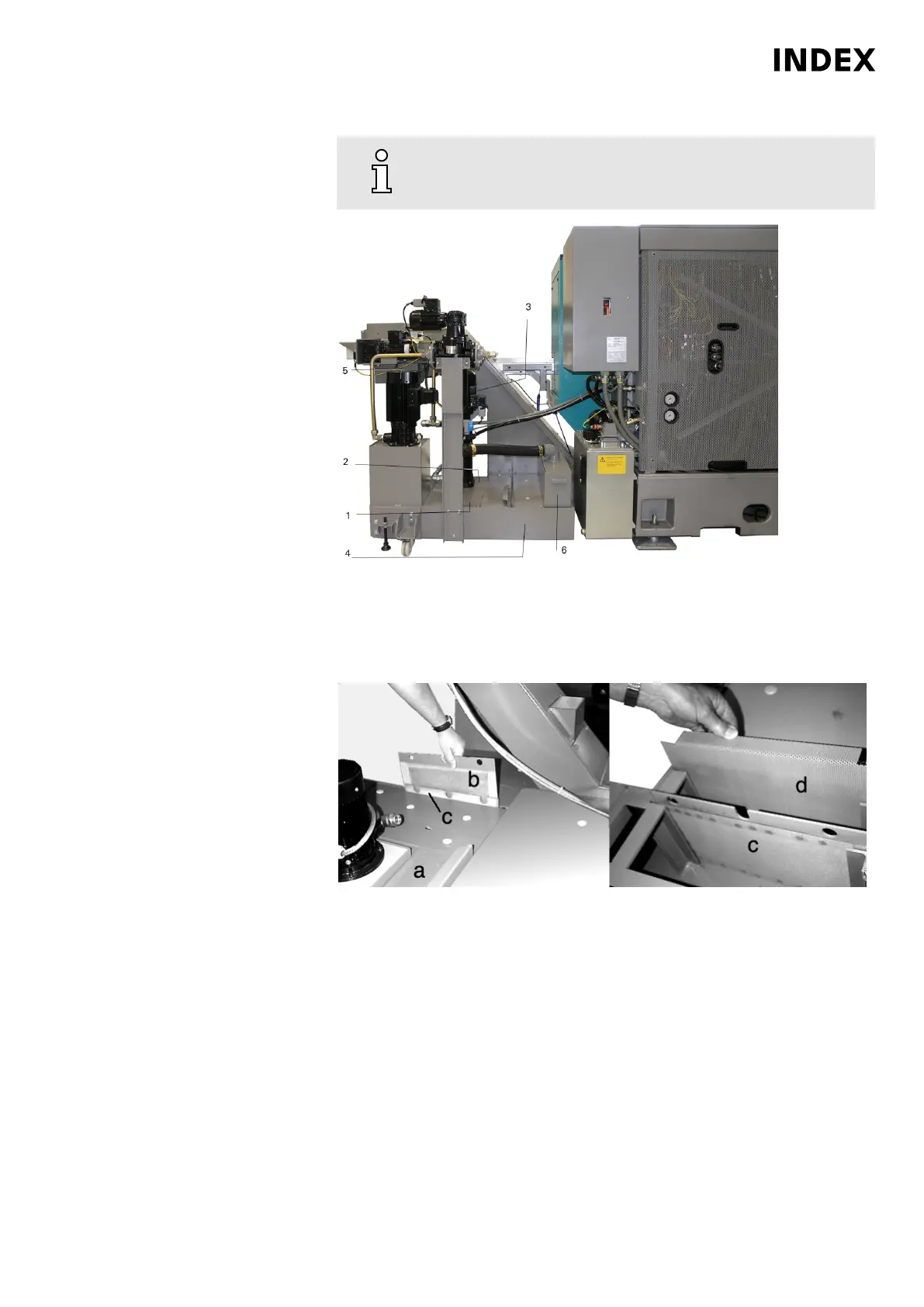

Example: Screens

a

Screen box

b Insert screen (dirty)

c Insert screen (cleaned)

d Coarse screen

Clean screens and magnetic filter plates (option). To avoid clogging of the

cooling lubricant channels, the insert screen, coarse screen and the magnetic

filter plate (option) should be cleaned weekly or as appropriate depending on

the degree of contamination of the chip conveyor. Insert a second, non-built-in

insert screen at the motor side. This prevents sludge deposits and chips from

entering the suction area of the pump. Then remove and clean the dirty screen,

and have it ready for the next maintenance interval.

6. Remove and clean pre-filters (option) on the cooling lubricant pump.

Maintenance Summary - Care activities

35

Maintenance Instructions

C200

LP1702.10021 - 05.06.2019

Loading...

Loading...