When switching the coolant to another product or changing the

manufacturer, the cooling system must be completely flushed and

cleaned with this coolant. When preparing the coolant from

concentrate and water, be sure to use demineralized water only. Only

then the machine may be put back into operation.

External Machine Cooling Water Supply

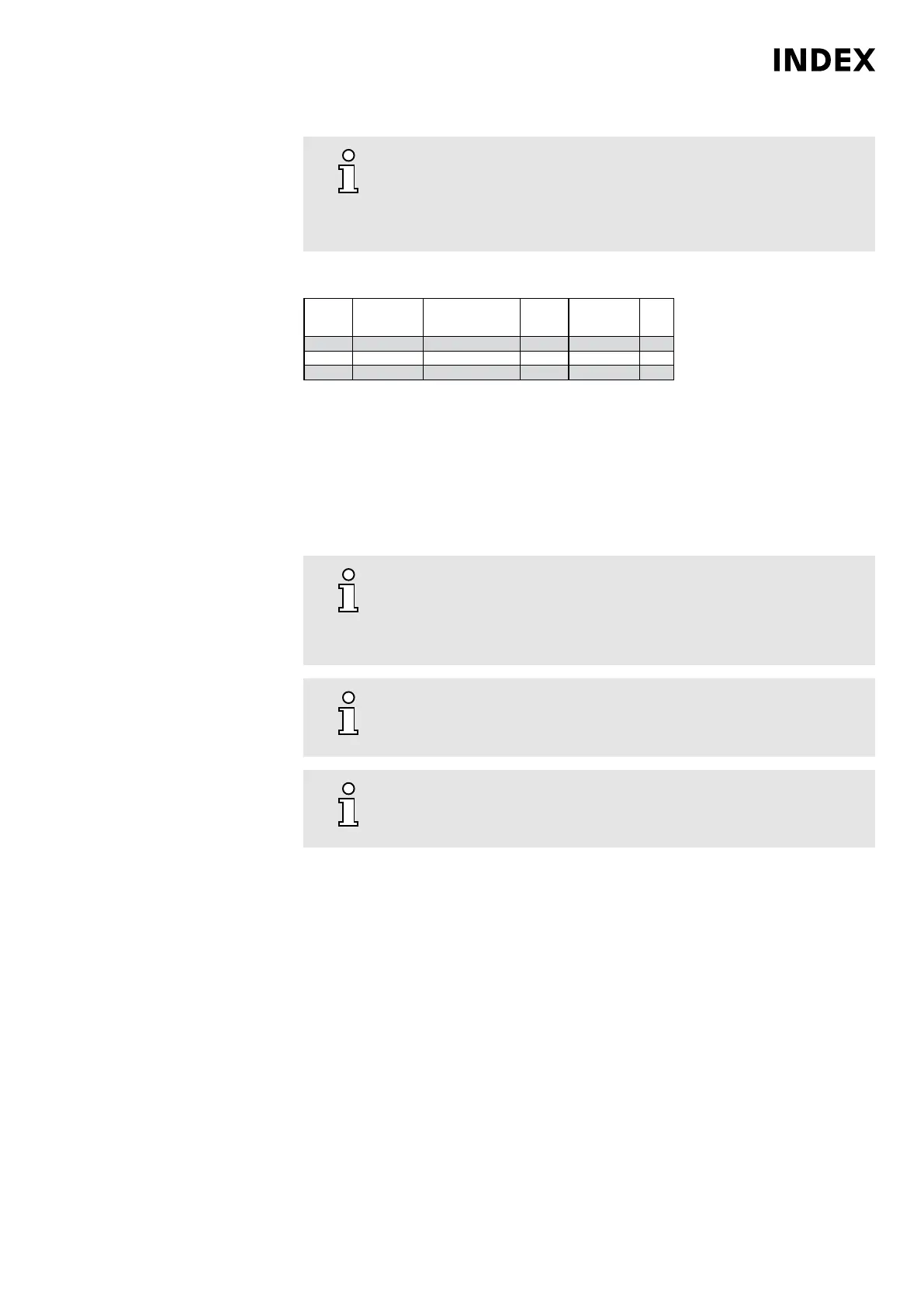

C100

C200

20°C±2°K

20°C±2°K

25 3 8

3

8

813

FA B C D E

25

Technical data of cooling water supply C100/C200

A Machine

B Water temperature [°C]

C Cooling water, Qmin / Qmax [l/min]

D Differential pressure P

inlet

and P

return

[bar]

E Required cooling capacity [kW]

F Pressure in the cooling system [bar]

The information given in the Technical Data of the cooling water apply at an ambient

temperature of max. 40 °C.

The values specified in the table must absolutely be observed!

Deviating from these values will not ensure sufficient cooling of the

machine.

The maximum operating pressure must not exceed 8 bar!

Due to different requirements and/or specifications of the respective

manufacturers, be sure to review the respective manufacturer's

documentation!

Be sure to replenish with a ready-mix. Mixing different glycol alkalis

may trigger chemical reactions causing agglutination or clumping of

the coolant.

Procedure

1. Check coolant. Test criteria for this visual inspection are the clarity and

transparency of the coolant.

Maintenance Summary - Care activities

29

Maintenance Instructions

C200

LP1702.10021 - 05.06.2019

Loading...

Loading...