4.

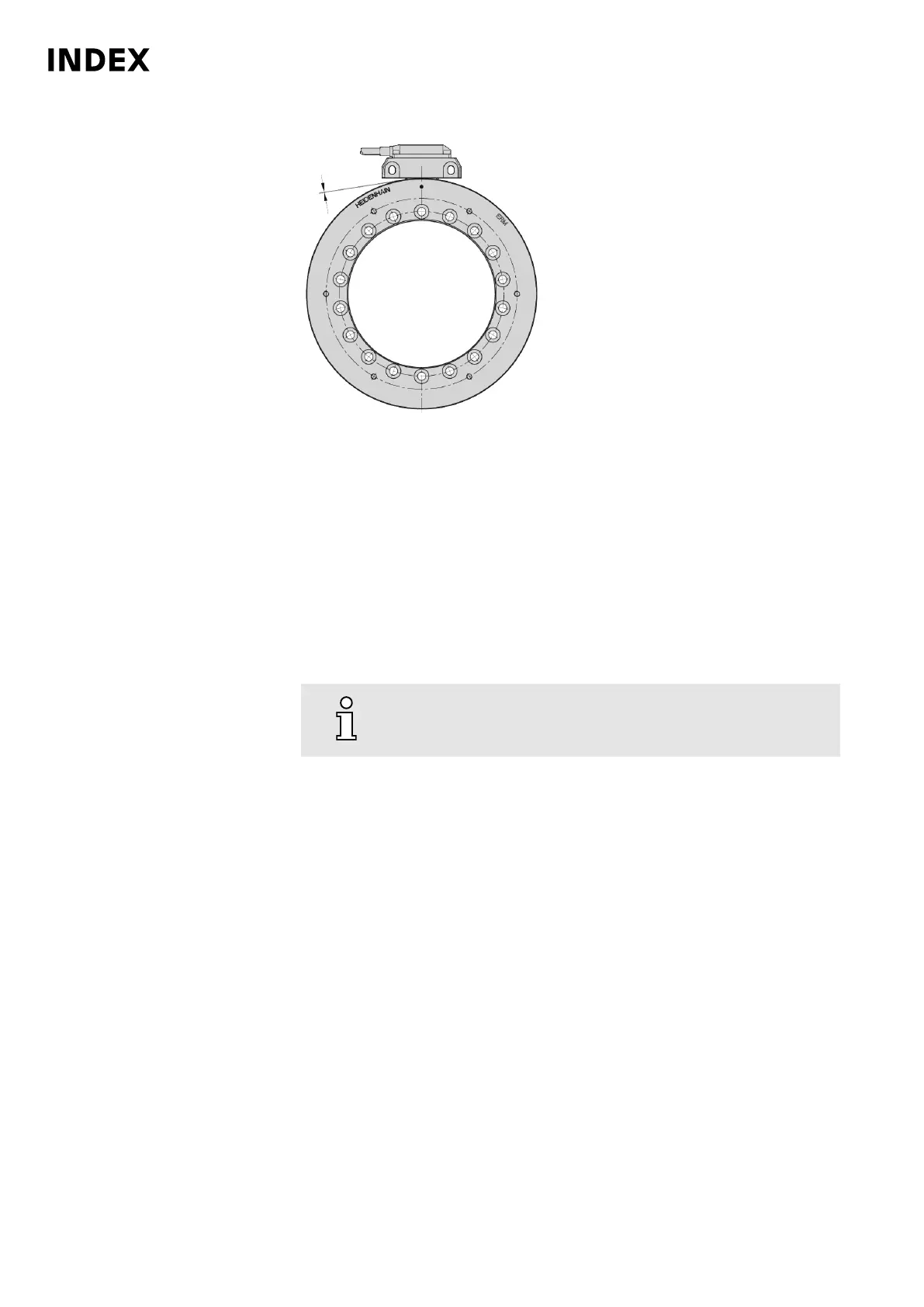

Example: Encoder wheel Heidenhain ERM

Clean encoder wheels. Do not use any metal tools or objects for cleaning.

To ensure optimum data exchange between the encoder and the encoder

wheel, the encoder wheel must be cleaned regularly. Ensure absolute

cleanliness, so that the cleaning does not lead to additional contamination of

the encoder wheel or the encoder.

5. Check the tightness of the hydraulic accessory units. Check the aligning and

indexing units, solid or open-center cylinders for leaks.

6. Check supply and exhaust pipes on the main and counter spindles. Defective

intake and exhaust air pipes on the main and counter spindles may cause

overheating and thus damage to the spindles.

7.

Whether air flow exists can quickly and easily be made visible

by attaching a thread at the opening of the air outlet.

Check filters on the air supply to the spindles. The use of dirty or incorrect filter

mats at the air intake can also lead to overheating and thus to damage to the

spindles. Be sure to use only original filters.

Maintenance Summary - 4.000 Operating hours

78

Maintenance Instructions

C200

LP1702.10021 - 05.06.2019

Loading...

Loading...