A190 - Checking the wiper of counter spindle guide in the work area

Orientation

Due to their open-access location, the counter spindle wipers may be contaminated

or impaired by chips particularly hard.

Therefore, special attention should be given to the condition of the wipers during

servicing and maintenance activities.

Requirement

As part of servicing and maintenance, only periodic visual inspection of the wipers is

necessary. However, if this visual inspection reveals damage to the wiper, it must be

replaced immediately.

Procedure

1.

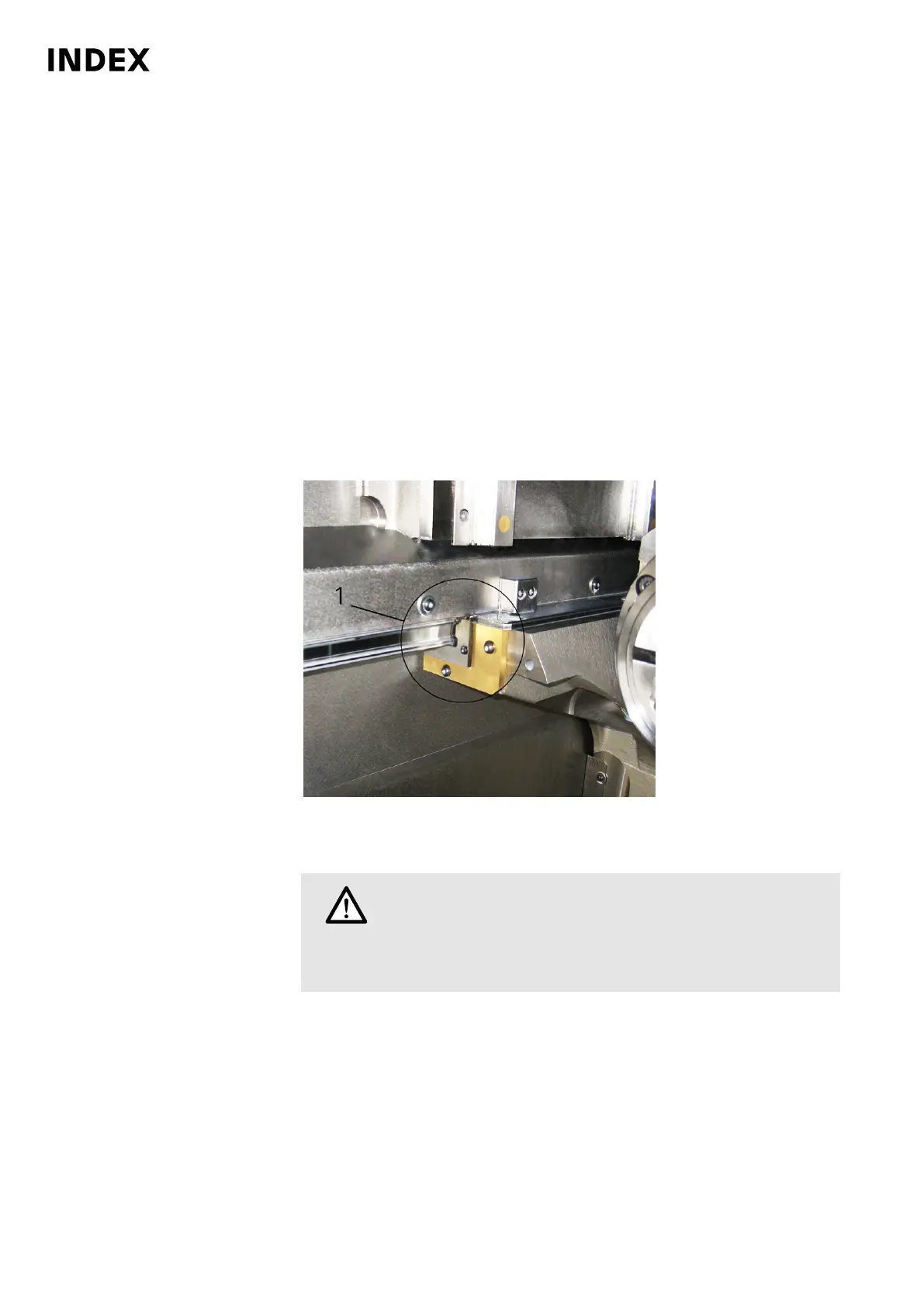

Example: wiper (1) counter spindle C100/C200

Bring counter spindle into working position.

2.

Caution

Uncontrolled movements of tool carriers or accessories.

Cuts and crush injuries to hands and arms.

Trigger an EMERGENCY STOP on the machine or switch off the

machine completely.

Check wipers.

3. Replace any defective wiper. Unscrew wiper and push to the left of the guide

bar. Be sure to clean the space behind the wiper before inserting the

new wiper.

4. Oil the cleaned guide bar. This allows the wiper to be pushed easily over the

guide bar. Slide new wiper carefully onto the guide bar.

Maintenance Summary - Care activities

32

Maintenance Instructions

C200

LP1702.10021 - 05.06.2019

Loading...

Loading...