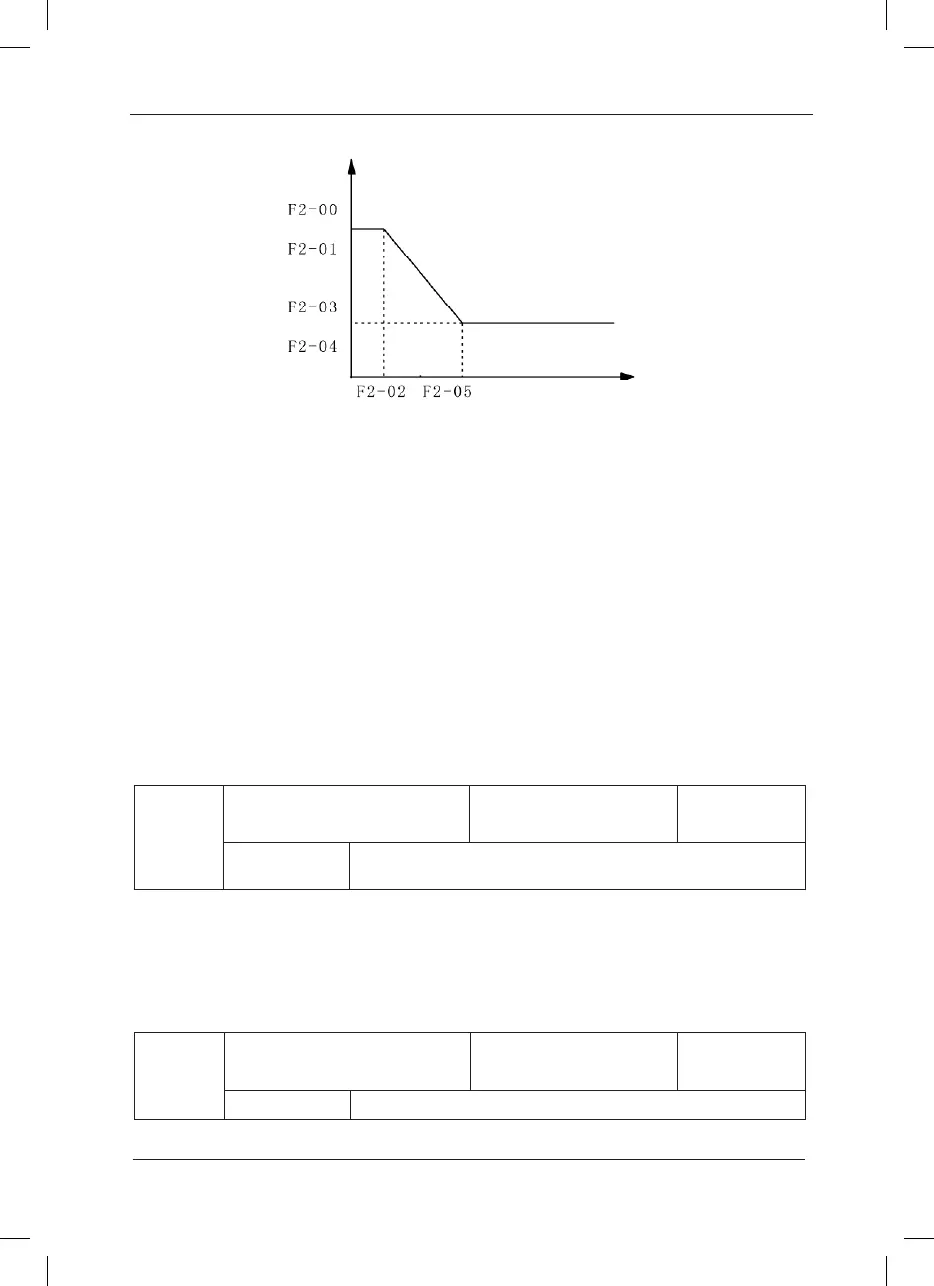

Fig.6-2 Schematic diagram of PI parameter

The speed dynamic response characteristics of the vector control can be adjusted by setting

the proportional coefficient and integration time of the speed regulator. Increasing the

proportional gain or reducing the integration time can accelerate the dynamic response of the

speed loop. However, if the proportional gain is too large or the integration time is too short, it

will cause the oscillation of the system.

Recommended adjustment method:

If the factory default parameters cannot meet the requirements, the relevant parameter values

can be subject to ne tuning.

Increase the proportional gain while ensuring no oscillation to the system, and then reduce

the integration time to ensure that the system has quick response characteristics and small

overshoot.

Caution: Improper PI parameter setting may cause too large speed overshoot. Voltage fault

may occur when the overshoot drops.

F2-06

Slip compensation

coefcient

Factory default value 100%

Setup range 50%~200%

F2-07

Time constant of speed loop

lter

Factory default value 0.000s

Setup range 0.000s~0.100s

For the speed sensorless vector control, this parameter is used to adjust the speed stabilizing

precision of the motor. When the speed is too low due to heavy load of motor, this parameter

needs to be enlarged or this parameters needs to be reduced.

For the speed sensor vector control, this parameter can adjust the output current of the inverter

carrying the same load.

Loading...

Loading...