5 System Commissioning

-

144

-

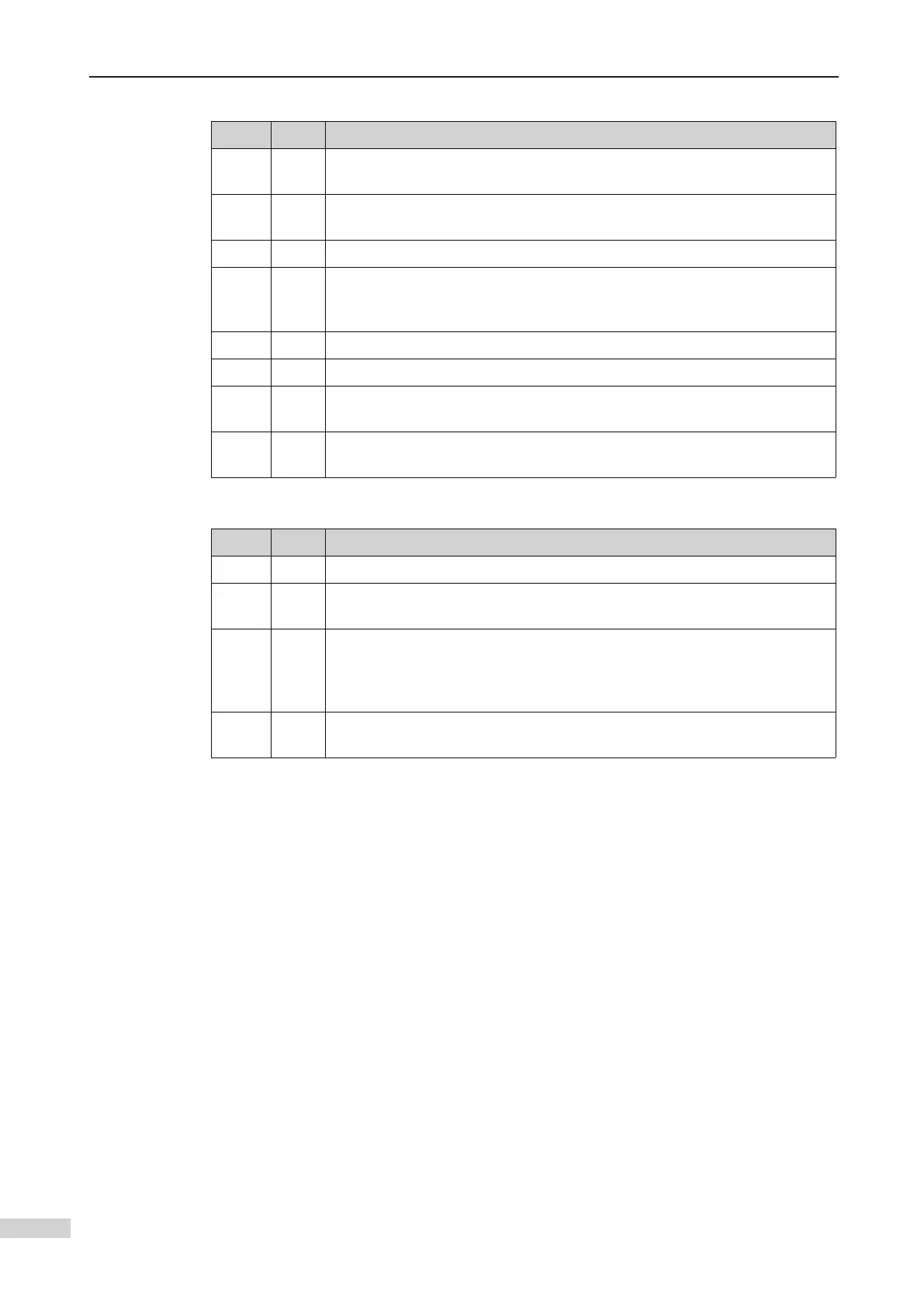

Step 3: Check electrical safety.

□√

No. Inspection Points

1

unbalance degree does not exceed 3%.

2

The total lead-in wire gauge and total switch capacity meet the

requirements.

3 There is no inter-phase or to-ground short circuit in the R, S, T power supply.

4

There is no inter-phase or to-ground short circuit in the U, V, W phases of the

controller. There is no to-ground short circuit in the U, V, W phases of the

motor.

5 There is no to-ground short circuit on the output side of the transformer.

6 There is no inter-phase or to-ground short circuit in the 220 V power supply.

7

The 24 V power supply has no short circuit between positive and negative or

to-ground short circuit.

8

The CANbus/Modbus communication cable has no short circuit with the 24

V power supply or short circuit to ground.

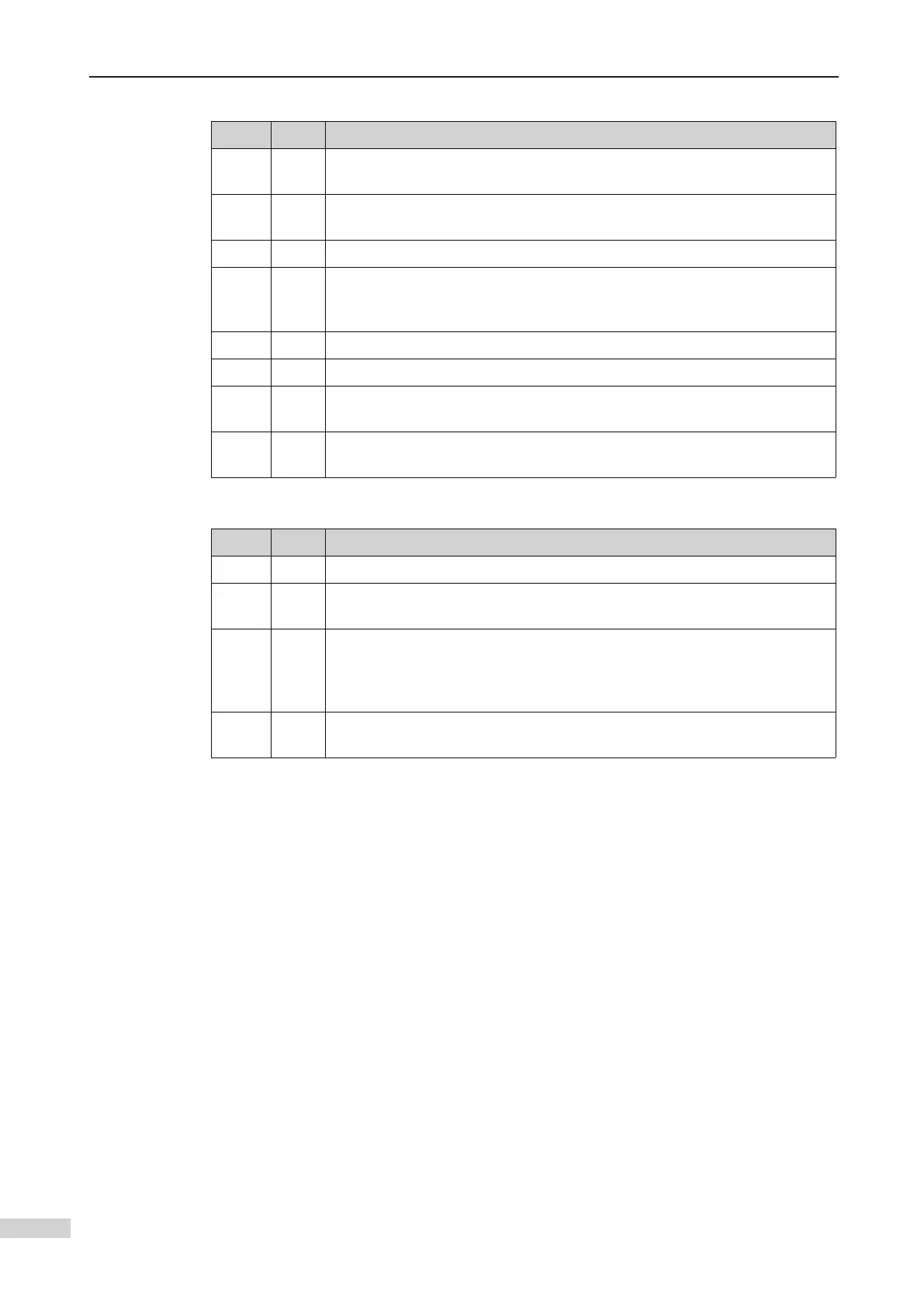

Step 4: Check the rotary encoder.

□√

No. Inspection Points

1 The encoder is installed reliably with correct wiring.

2

ducts to prevent interference.

3

The encoder cables are preferably directly connected to the control cabinet.

If the cable is not long enough and an extension cable is required, the

extension cable must be a shielded cable and preferably welded to the

original encoder cables by using the soldering iron.

4

The shield of the encoder cables is grounded on the end connected to the

controller (only one end is grounded to prevent interference).

Loading...

Loading...