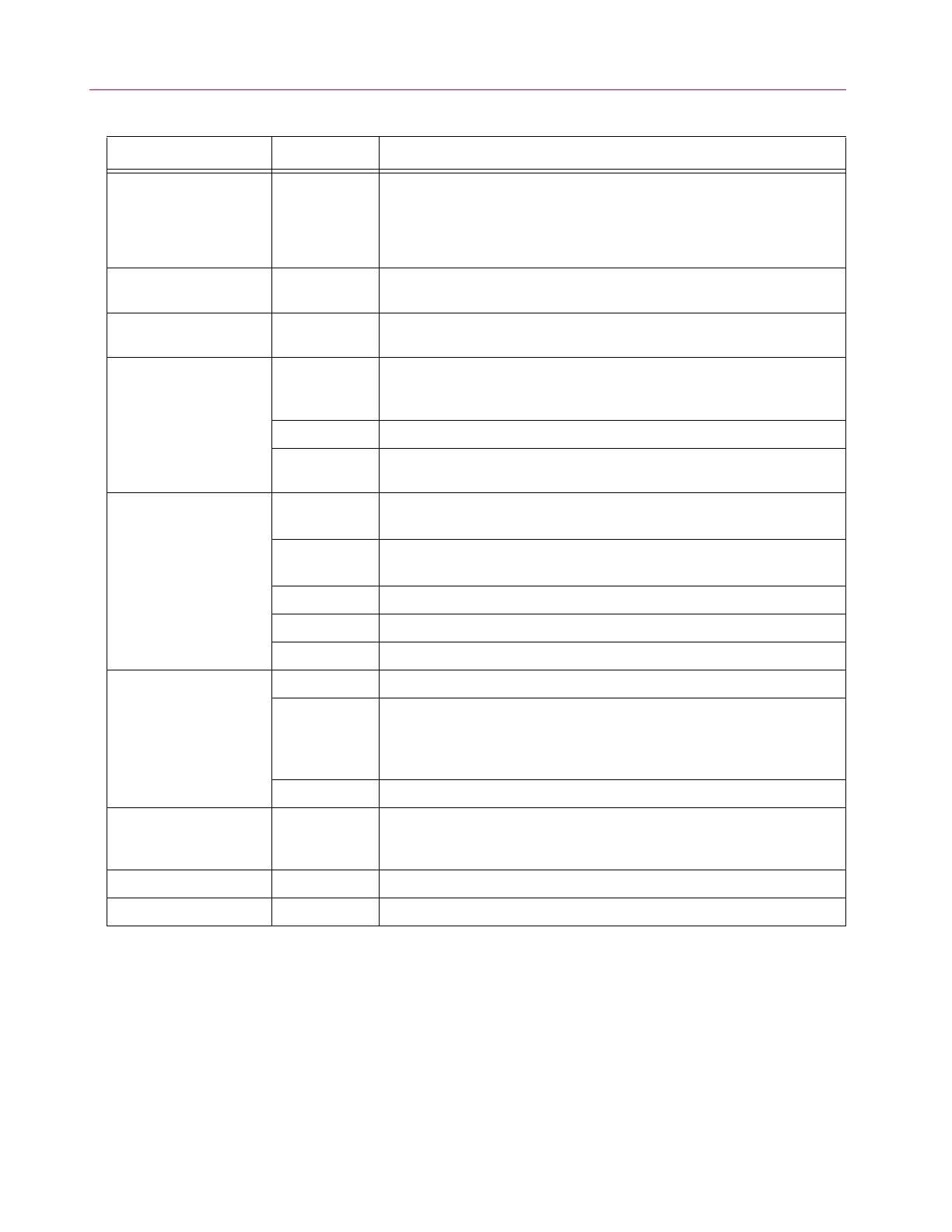

Chapter 4: Maintenance

62 M47-17027-EN

Daily or after every 50

consecutive tests: Grip assemblies

of G7-style

crossheads

• For 600DX frames: The tightness of the retainer setscrew should be

checked daily or after 50 consecutive tests are performed with the same

set of grip jaws. The retainer setscrews can vibrate loose and allow the

grip jaws to fall out of the jaw carriers. See “Install grip jaws - G7-style

crossheads” on page 50.

Weekly or after every

150-300 tests

2

:

Grip assemblies

• Lubricate the grip assemblies; see page 72.

1

Monthly or after every

2000 tests

2

:

Grip assemblies

• Clean and inspect grip components; see page 73.

1

Monthly:

System

• Visually inspect all hoses (exposed and hidden) and around the base of

the frame for signs of oil leakage. Investigate any abnormal or excessive

leakage and correct appropriately.

Frame

• Check non-painted surfaces; see page 66.

HPS

• Check level of oil in reservoir and add oil as necessary. Refer to “Add oil

to reservoir” on page 80.

Biannually

(or once every 1000 hrs.

of operation)

2

:

System

• Inspect the hydraulic hoses; see page 85.

• Inspect the cables; see page 66.

Frame

• Inspect the adjustable crosshead; see page 67.

• Inspect the hydraulic cylinder; see page 70.

HPS • Check the oil cleanliness; see page 80.

•

3

Electronics • Clean the fans; see page 66.

3

:

Annually

(or once every 2000 hrs.

of operation)

2

:

System

• Verify/Calibrate system.

HPS

• Change the air breather filter; see page 85.

• For special operating conditions where oil temperature is continuously

between 60 and 80 deg. C (140 and 176 deg. F) - Change the oil; see

page 83.

Frame

• Lubricate the adjustable crosshead; see page 67.

Biennially

(or once every 4000 hrs.

of operation)

2

:

HPS

• For normal operating conditions where oil temperature is continuously

below 60 deg. C (140 deg. F) - Change the oil; see page 83.

Every 5 years: System

• Replace high pressure hydraulic hoses; see page 86.

Every 7 years: System • Replace low pressure hydraulic hoses; see page 86.

1. The frequency listed here for maintenance of the grip assemblies is only a recommendation. The correct frequency for your

grips is heavily dependent on how often the grips are used, the environmental conditions in which the grips are used, and

the type of specimens that are tested. Frequent use or dirty environments may require more frequent maintenance, while

less frequent use or clean laboratory conditions could require less. We recommend beginning with the frequency listed

here and then adjusting this frequency as experience dictates. Also, the lower grip may require more frequent cleaning

than the upper grip, simply because it will tend to collect more dirt and debris.

2. Whichever is soonest.

3. The frequency listed here is only a recommendation. The correct frequency for your system is heavily dependent on the

environmental conditions in which your system is used. Dirty environments may require a more frequent interval, while

clean laboratory conditions could require less. We recommend beginning with the frequency listed here and then adjusting

this frequency as experience dictates.

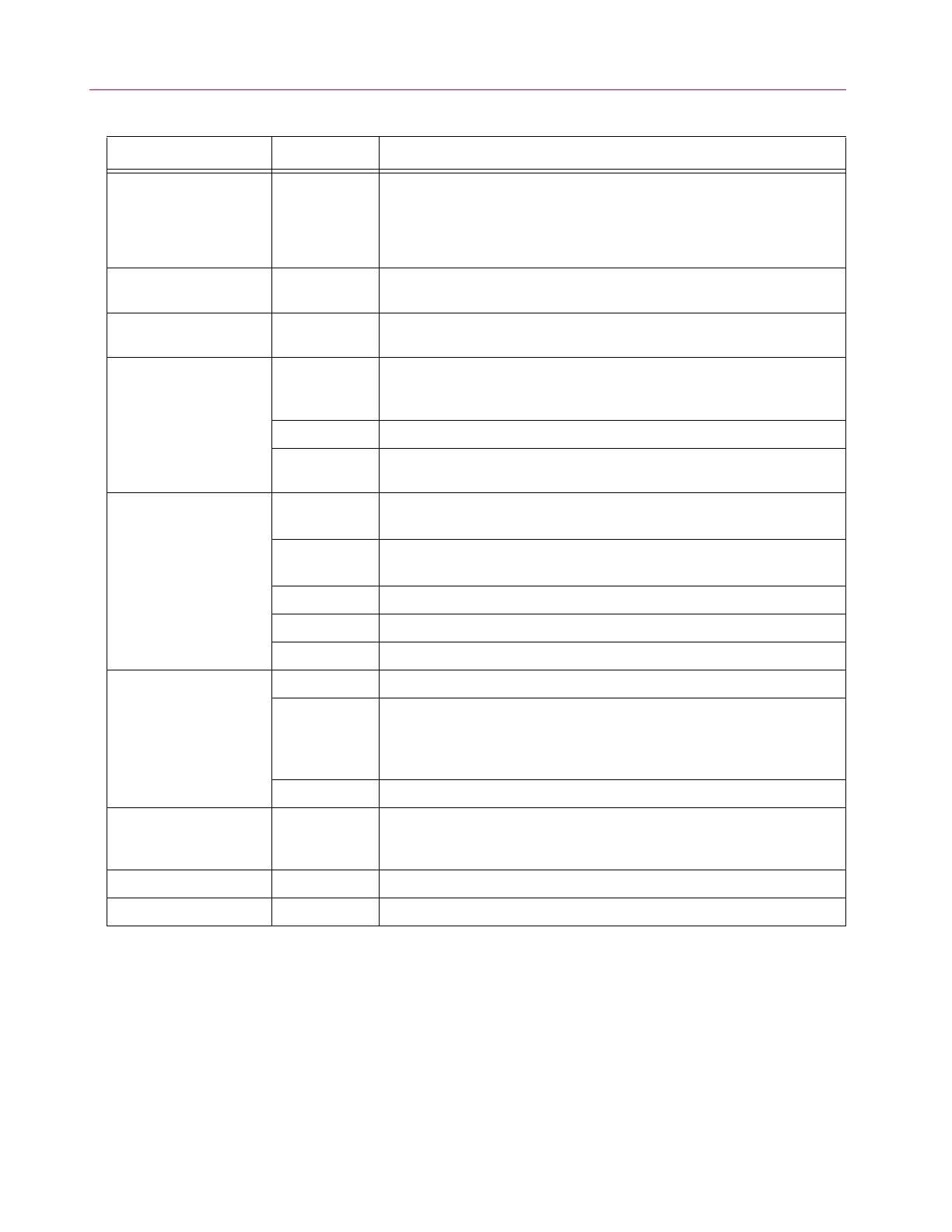

Table 14. Recommended preventative maintenance schedule. (Continued)

Frequency Component Maintenance Task

Loading...

Loading...