8 7 6 5 4 3 2

H

G

F

E

D

C

B

A

8 7 6 5 4 3 2 1

H

G

F

E

D

C

B

A

A

A

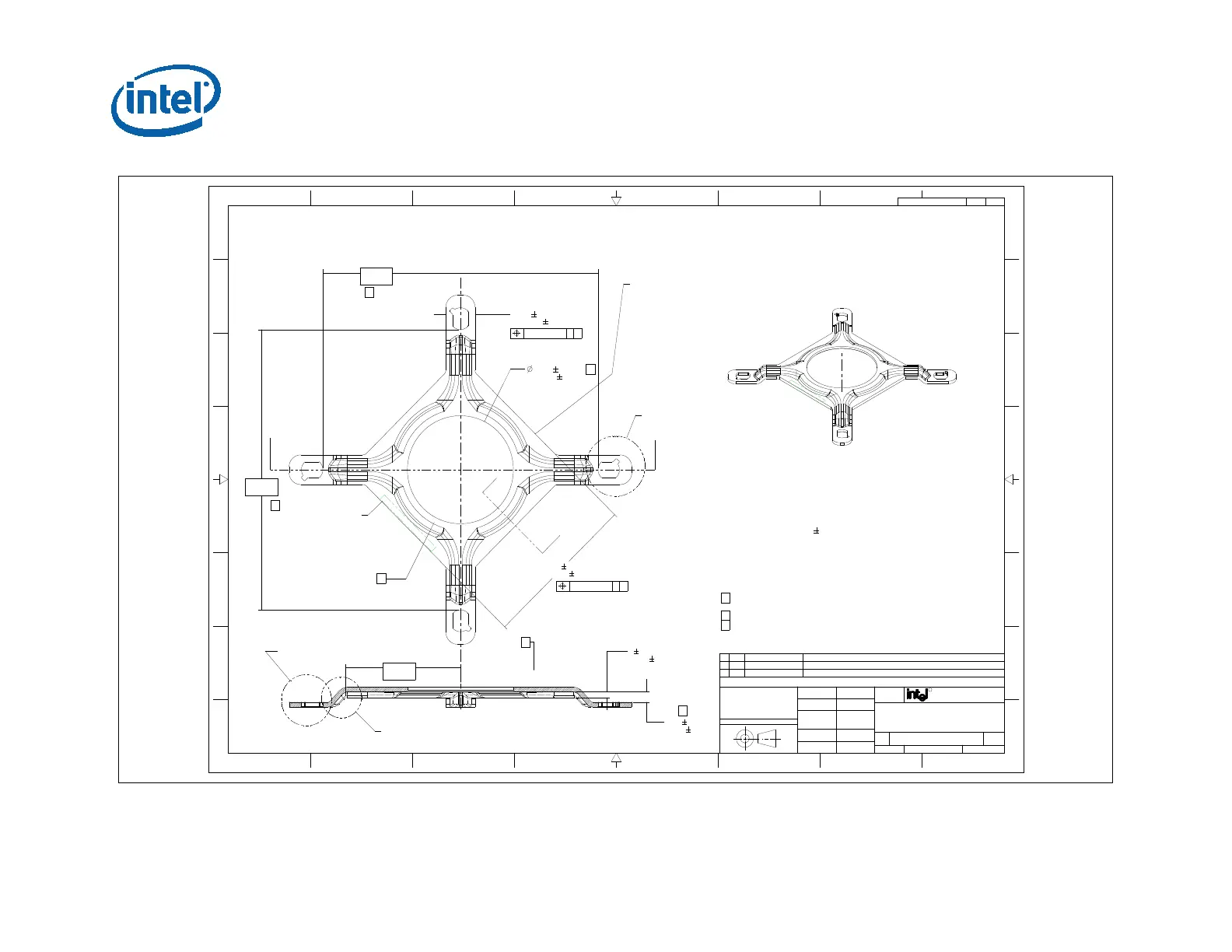

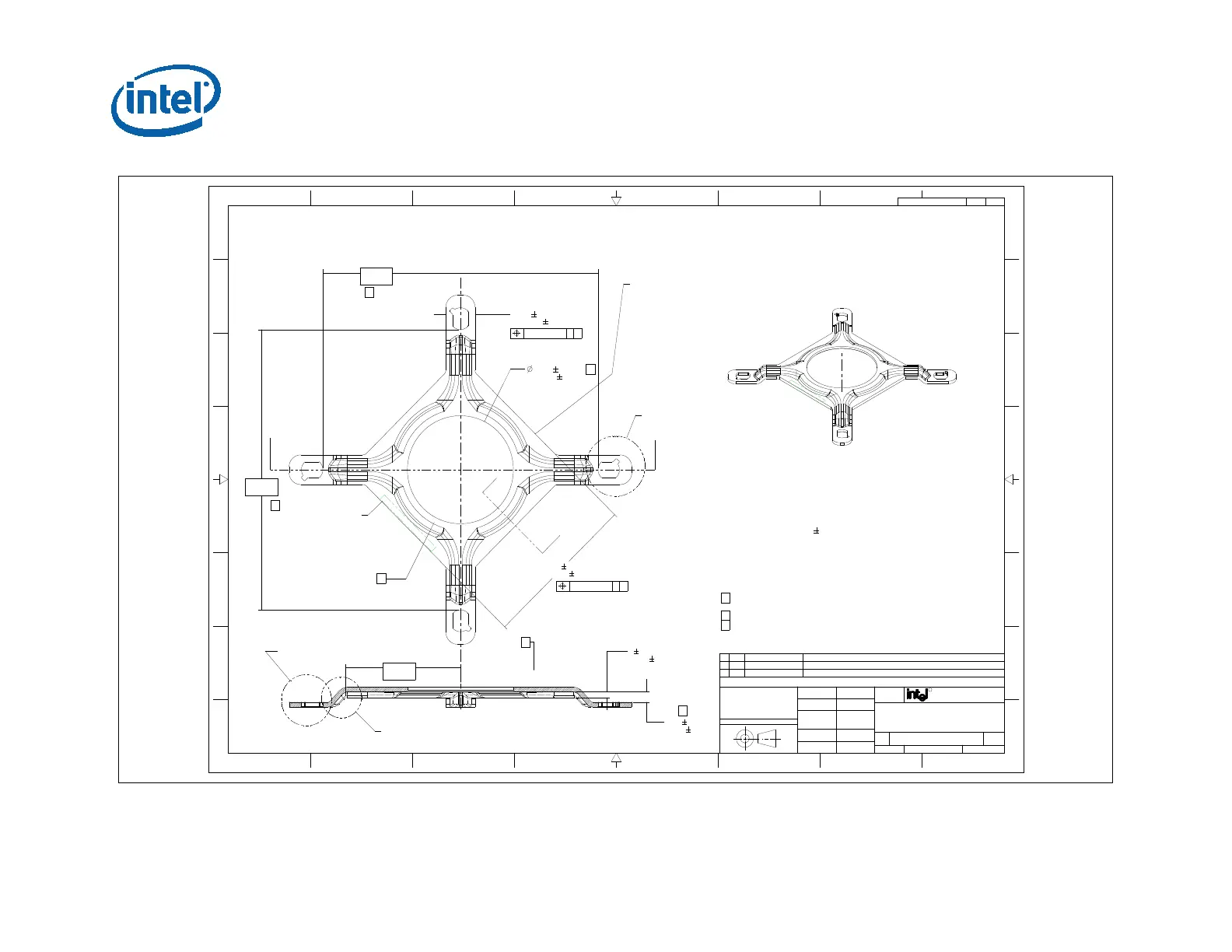

2

0.2

.079

.007[ ]

3.52 0.2

.139

.007[ ]

94.62

3.725[ ]

SQ 53.5 0.2

2.106

.007[ ]

94.62

3.725[ ]

4X 10 0.2

.394

.007[ ]

39.6

1.559[ ]

736.44

0.2

1.435

.007[ ]

B

C85609 1 B

DWG. NO SHT. REV

DEPARTMENT

R

CORP.

2200 MISSION COLLEGE BLVD.

P.O. BOX 58119

SANTA CLARA, CA 95052-8119

TMD

TITLE

RCFH4 HS CLIP, 35mm core

SIZE DRAWING NUMBER REV

A1 C85609 B

SCALE: NONE

DO NOT SCALE DRAWING

SHEET

1

OF

2

UNLESS OTHERWISE SPECIFIED

INTERPRET DIMENSIONS AND TOLERANCES

IN ACCORDANCE WITH ASME Y14.5M-1994

DIMENSIONS ARE IN MILLIMETERS

ALL UNTOLERANCED LINEAR

DIMENSIONS ± 0.1

ANGLES ± 0.5

THIRD ANGLE PROJECTION

PARTS LIST

DESCRIPTIONPART NUMBER

ITEM NO

QTY

CLIP, STEEL, STAMPEDC85609-001TOP

0.5 [.019] A B

7

7

0.5 [.019] A B

NOTES:

1. THIS DRAWING TO BE USED IN CONJUNTION WITH SUPPLIED 3D

DATABASE FILE. ALL DIMENSIONS AND TOLERANCES ON THIS

DRAWING TAKE PRECEDENCE OVER SUPPLIED FILE AND ARE

APPLICABLE AT PART FREE, UNCONSTRAINED STATE UNLESS

INDICATED OTHERWISE.

2. MATERIAL:

A) TYPE: AISI 1065 COLD DRAWN STEEL OR EQUIVALENT

1.6MM THICKNESS

B) CRITICAL MECHANICAL MATERIAL PROPERTIES

FOR EQUIVALENT MATERIAL SELECTION:

ELASTIC MODULUS > 206.8 GPA [29,900 KSI]

MIN TENSILE YIELD STRENGTH (ASTM D638) > 490 MPa [71KSI]

C) MASS - 35.4 GRAMS (REF)

3. SECONDARY OPERATIONS:

A) FINISH: NICKEL PLATE REQUIRED AFTER FORMING

4. ALL DIMENSIONS AND TOLERANCES ARE SHOWN AFTER PLATING

5 PUNCH DIRECTION

6. BREAK ALL SHARP CORNERS AND BURRS

7 CRITICAL TO FUNCTION DIMENSION

8 COINING REQUIRED AS SPECIFIED

9. SECONDARY UNIT TOLERANCES SHOULD BE CALCULATED FROM PRIMARY

UNITS TO AVOID ROUND OFF ERROR.

5

7

REMOVE ALL BURRS OR SHARP EDGES AROUND PERIMETER OF PART.

SHARPNESS OF EDGES SUBJECT TO HANDLING ARE REQUIRED TO

MEET THE UL1439 TEST.

PERMANENTLY MARK PART

NUMBER AND REVISION LEVEL

APPROXIMATELY WHERE SHOWN

XXXXXX-XXX REV XX

SEE DETAIL A

SECTION A-A

SEE DETAIL C

SEE DETAIL B

SEE DETAIL A

SEE DETAIL C

SEE DETAIL B

D

D

Loading...

Loading...