Acoustic Fan Speed Control

R

56 Thermal/Mechanical Design Guide

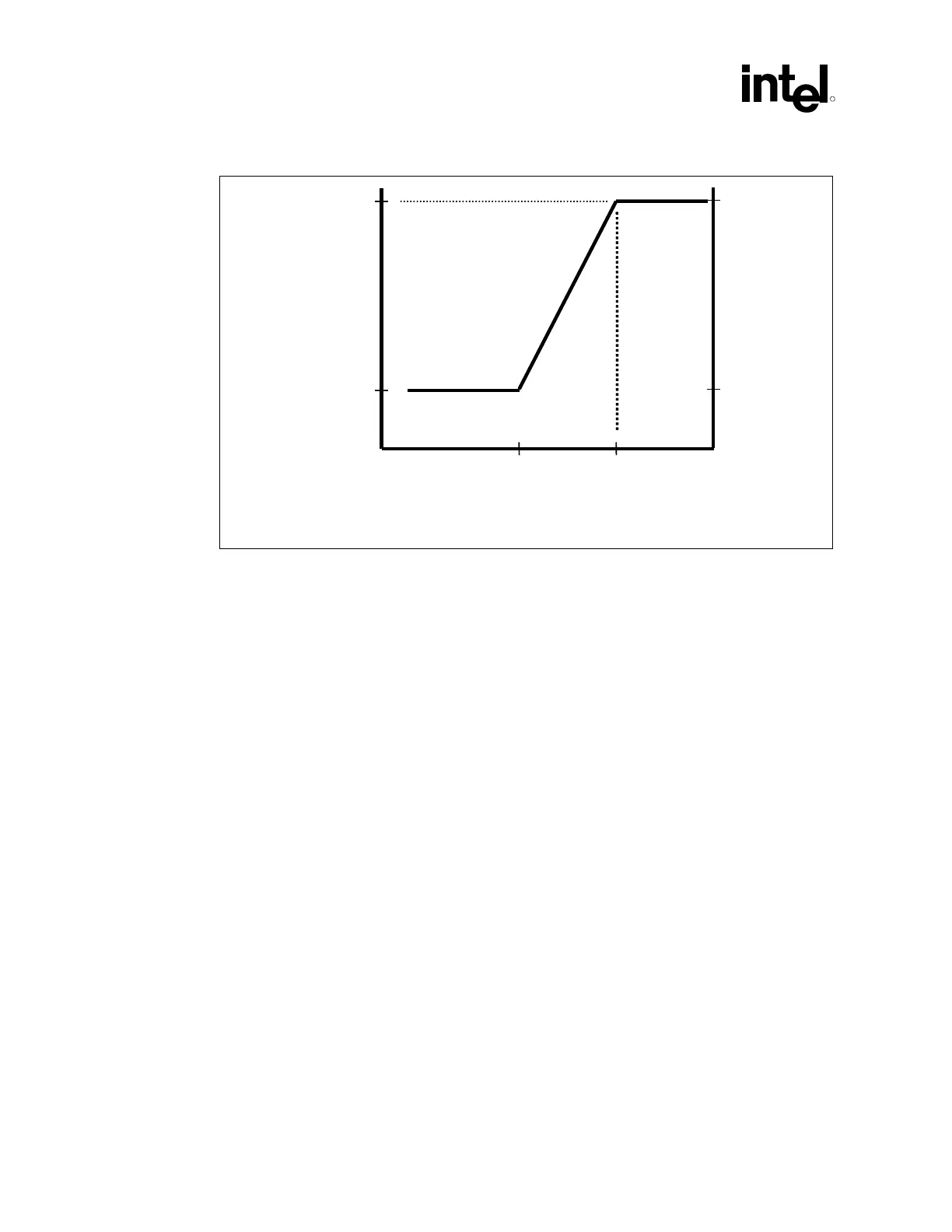

Figure 18. Fan Speed Control

Diode Temperature

(°C)

T

CONTROL

Min Speed

Fan Speed

(RPM)

Full Speed

T

LOW

X %

Fan Speed

(% PWM Duty Cycle)

100 %

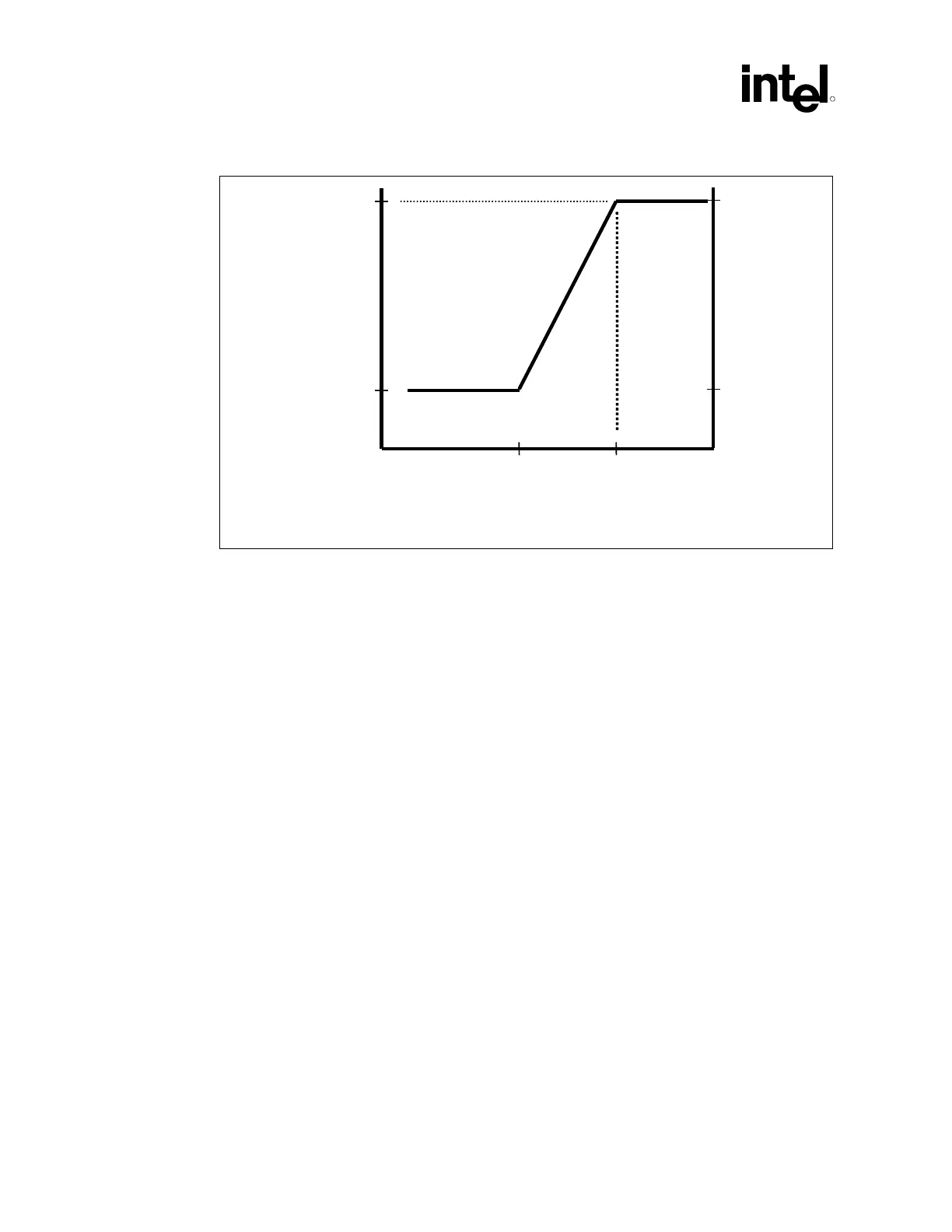

Diode Temperature

(°C)

T

CONTROL

Min Speed

Fan Speed

(RPM)

Full Speed

T

LOW

X %

Fan Speed

(% PWM Duty Cycle)

100 %

6.3.1.1 Temperature to begin Fan Acceleration

The first item to consider is the value for T

LOW

. The FSC device needs a minimum temperature to

set as the threshold to begin increasing PWM duty cycle to the fan.

The system designer might initially consider a small temperature range

(T

CONTROL

– T

LOW

= T

RANGE

), such as 5 °C to accelerate the fan. That would delay the fan

accelerating for the longest period after an increase in T

DIODE

. There are a number of issues that

should be considered with this strategy:

• There is little granularity in the fan speeds. For each 1 °C of increase in diode

temperature = 20% jump in PWM duty cycle %.

• Fan speed oscillation as the thermal solution chases the diode temperature.

• Having T

DIODE

overshoot T

CONTROL

and the thermal profile causing the Thermal Control

Circuit to activate to reduce the temperature.

The first two cases can create a poor acoustic response for the user. For the third case, the user

could notice a drop in performance as the thermal control circuit reduces the power.

Figure 19 is

an example of this situation. The system begins at idle and a moderate workload is applied (less

than TDP).

Loading...

Loading...