CS750 User Manual

Rev E, April 2018

Page 29 of 31

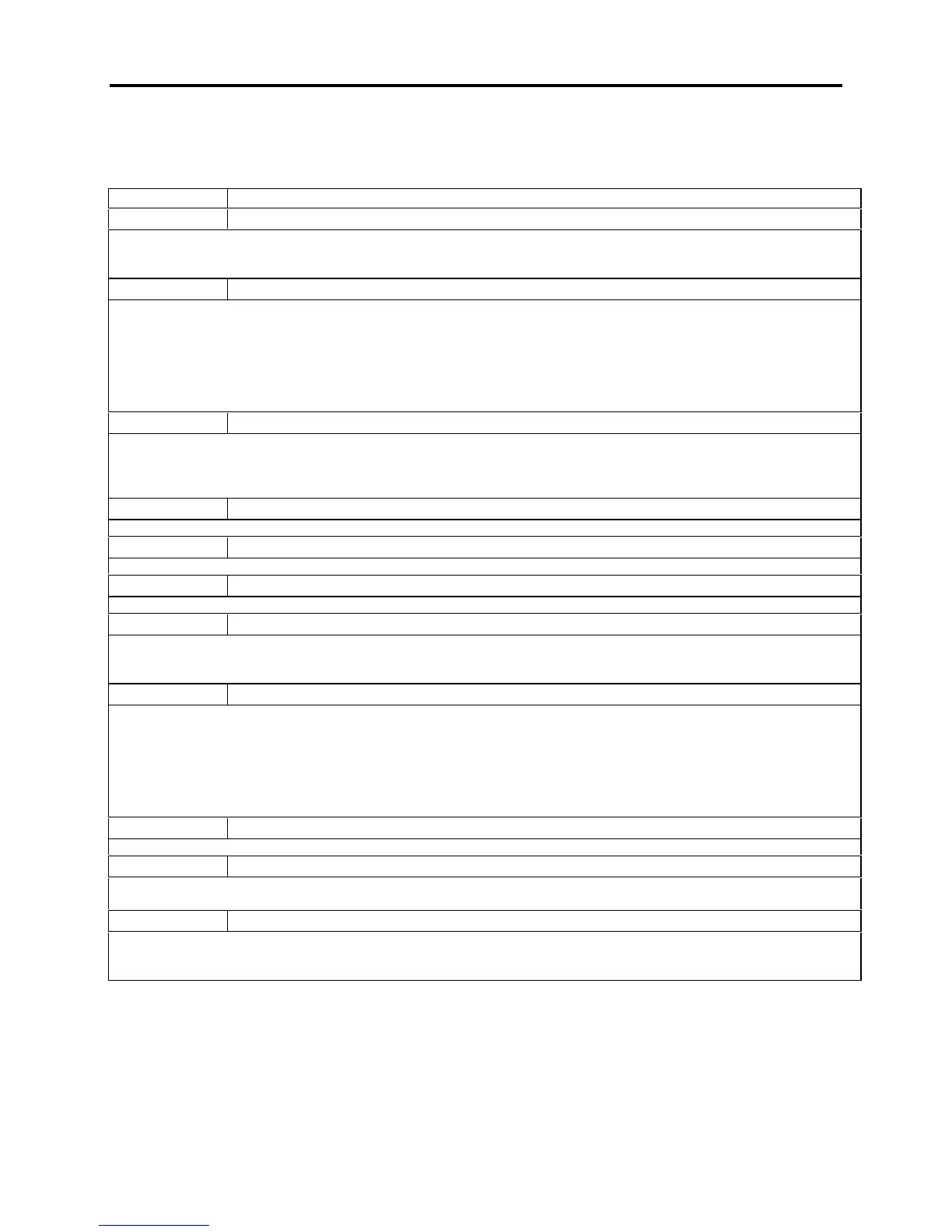

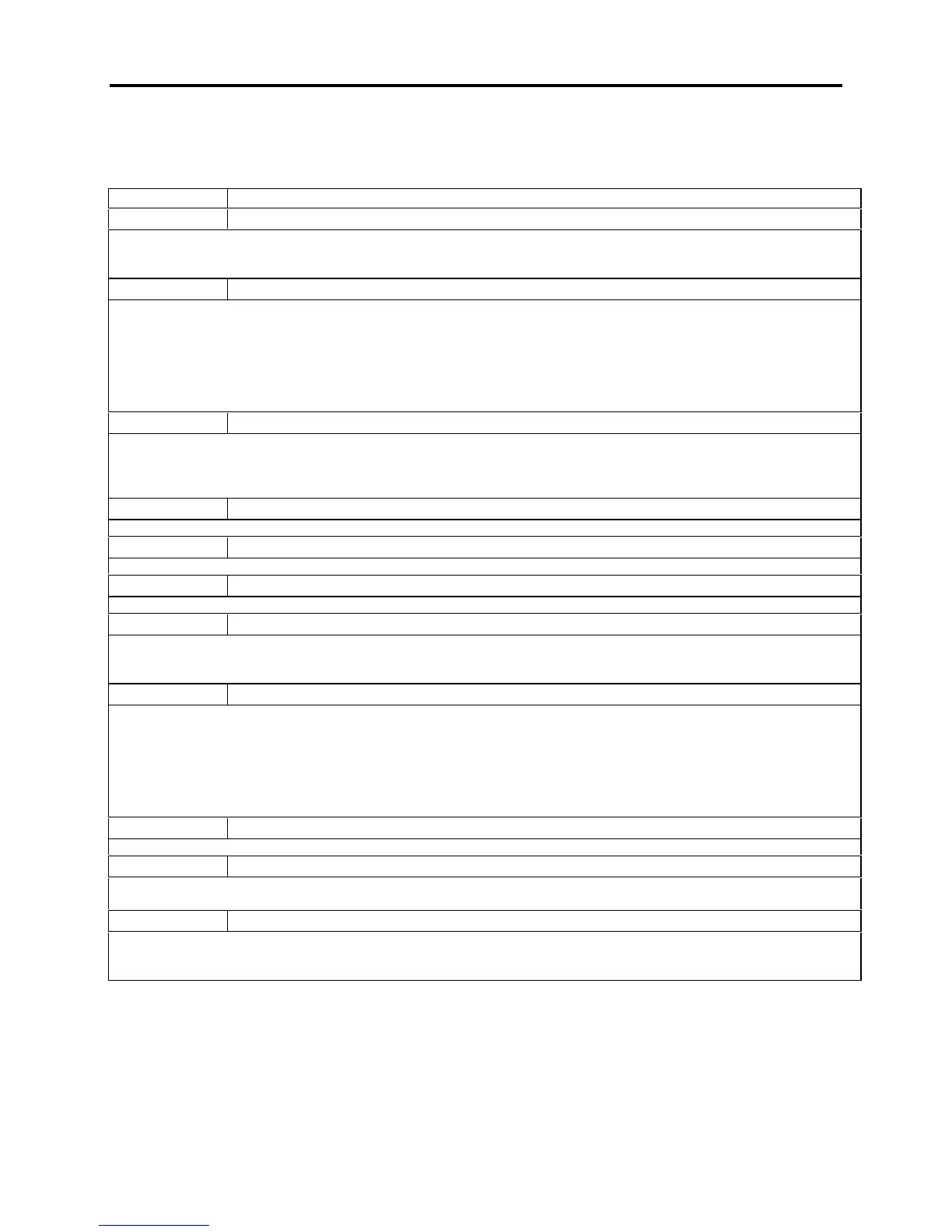

Error Messages

Refer to the Error Message table for message types and descriptions.

Motion Detected While Attempting to ZERO/TARE/PRINT/ACCUM

The message and the "MOTION" segment will briefly show when motion is detected when attempting to set zero, set

TARE or print ticket. The motion detection function can be disabled in the calibration menu under “Motion Detect".

However, checking for motion is required for NTEP applications.

Motion Detected While Attempting to Accumulate Total

The message will be displayed if a restriction is detected when attempting to accumulate to total:

1. Weight must return to zero in between weight accumulations.

2. Weight must be greater than zero to accumulate.

3. Weight must be stable (not in motion) to accumulate.

When motion detection is the cause for preventing an accumulation to take place, the "MOTION" segment will also be

displayed when the error code message is present. The motion detection function can be disabled in the calibration

menu under “Motion Detect". However, checking for motion is required for NTEP applications.

EEPROM FAILURE Calibration Information Lost or Corrupted

Calibration information is held in a special permanent memory area. A checksum code is generated and written to the

memory during the calibration process. Each time power is turned on, the code is regenerated and compared to the

stored value. If a change is detected, error message will be displayed. Recalibration may clear the error display. If the

problem persists the control panel may need to be replaced.

The A/D circuit board has detected a fault and will require repair or replacement.

Power-Up Self-Test Has Detected Load Cell Error

The load cell may have failed or there is a bad connection.

Run-Time Checking Has Detected Load Cell Error

The load cell may have failed or there is a bad connection.

The message indicates that the control panel has measured the battery voltage and found it to be too low. The most

likely cause is that the batteries need to be changed. If a new set of batteries fail to correct the situation, then the

control panel may need to be replaced. A check of the battery holder and associated wiring should also be performed.

Overload or Calibration Information Lost or Bad Load Cell

The control panel has detected a weight reading that is over the capacity of the scale or is out of the expected mV/V

range. This may be caused by the application of excessive weight on the platform. If the message is displayed when

there is no weight on the platform, the most likely cause would be a defective load cell or defective control panel. To

isolate the problem, measure the signal across pins 2 and 3 of the load cell connector located on the control panel. The

reading should be between zero and one millivolt. If the reading is found to be higher or lower, then the load cell system

should be checked. If the signal is within the designated range then the calibration data may be lost. Attempt to

recalibrate the scale. If this does not clear the problem, then replace the control panel.

Weight display is too large to fit on the display. Remove existing load and press zero.

Scale attempted to zero off a load outside the range specified in the zero range setting. Remove existing load and

press zero.

This message will blink if a TARE entry was attempted with graduations that do not match the grad settings. For

example, if the display graduations are set to "2 lb", a TARE entry of "19 lb" would not be accepted. In this situation a

graduation of either 18 or 20 lbs. should be entered.

Loading...

Loading...