22

Version 1.0 (11/2007) en

Original language

Assembly

RollerDrive EC200

Securing the RollerDrive in

the conveyor frame

There is a nut and a washer on the shaft next to the tube. This inner nut has been

preassembled and secured in the correct position.

¾ Prevent the inner nut from rotating with a flattened wrench AF 19 mm. For

IP66 configuration use a flattened wrench AF 36 mm.

¾ Slip a second star washer and a hex nut over the motor cable and screw it

onto the threaded motor shaft. Ensure that star washers are mounted on both

sides of the profile.

¾ Use a torque wrench to tighten this outer nut with 35 Nm (308 in-lbf) while

ensuring that the inner nut is not rotating.

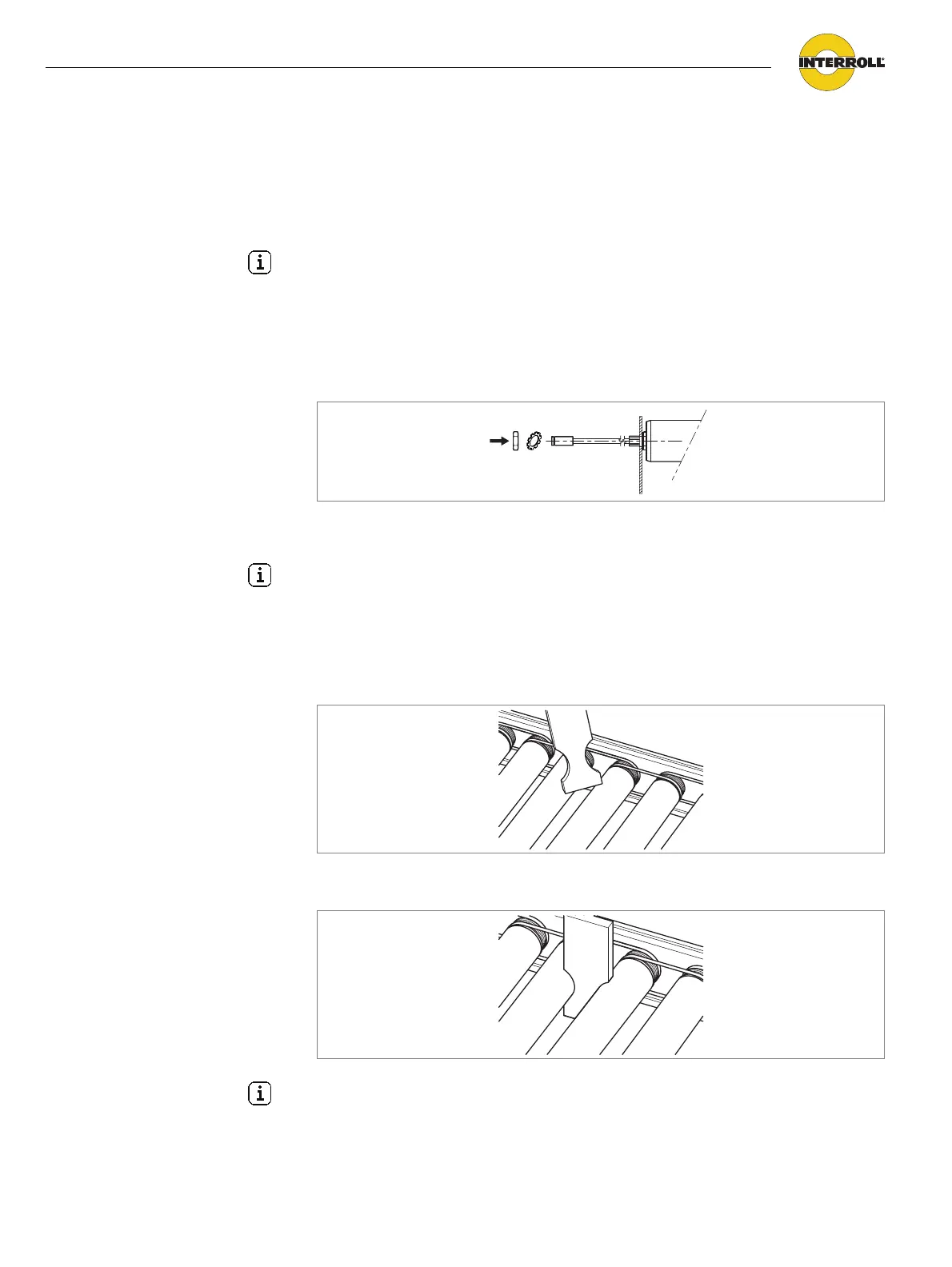

Mounting tool

For mounting the multi-rib belt, you may want to build a mounting tool as shown

in the figure below.

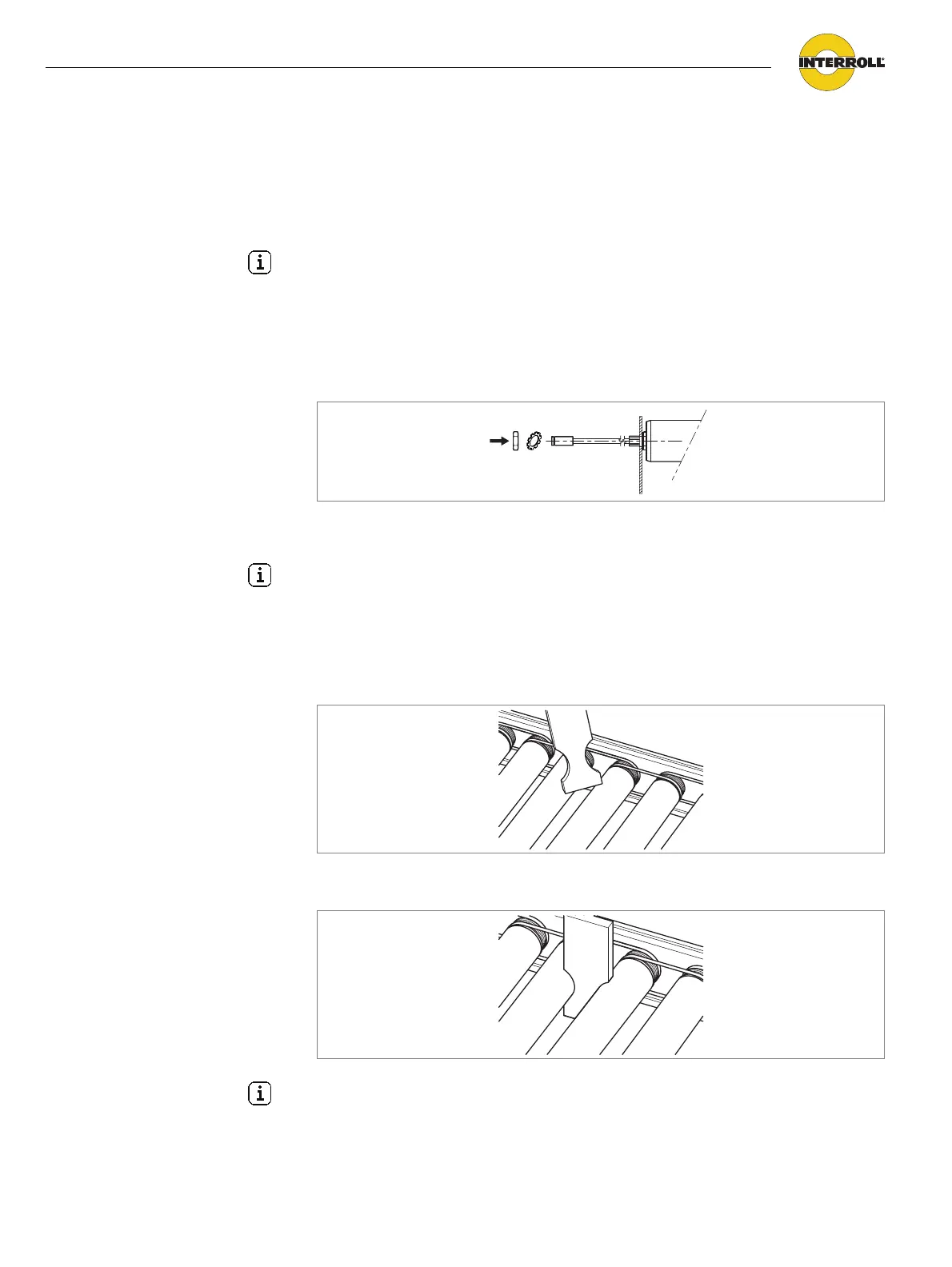

¾ Place the mounting tool between two rollers to reduce the gap between the

adjacent rollers.

Hint

Do not adjust the inner nut and washer.

Hint

To prevent bending forces on conical RollerDrives, an angular compensation on

the motor end is needed.

Hint

The dimensions of the mounting tool depend on the roller pitch and the roller

tube diameter.

Loading...

Loading...