Goodrive350 series high-performance multi-function inverter Chapter 6

-132-

Detailed parameter description

synchronous

motor 1

(reserved)

Overload

protection of

motor 1

0: No protection

1: Common motor (with low-speed compensation).

As the cooling effect of common motor will be

degraded in low speed, the corresponding electronic

thermal protection value should also be adjusted

properly, the low compensation here means to lower

the overload protection threshold of the motor whose

running frequency is below 30Hz.

2: Frequency-variable motor (without low speed

compensation). As the cooling effect of

frequency-variable motor is not affected by the

rotating speed, there is no need to adjust the

protection value during low speed running.

Overload

protection

coefficient of

motor 1

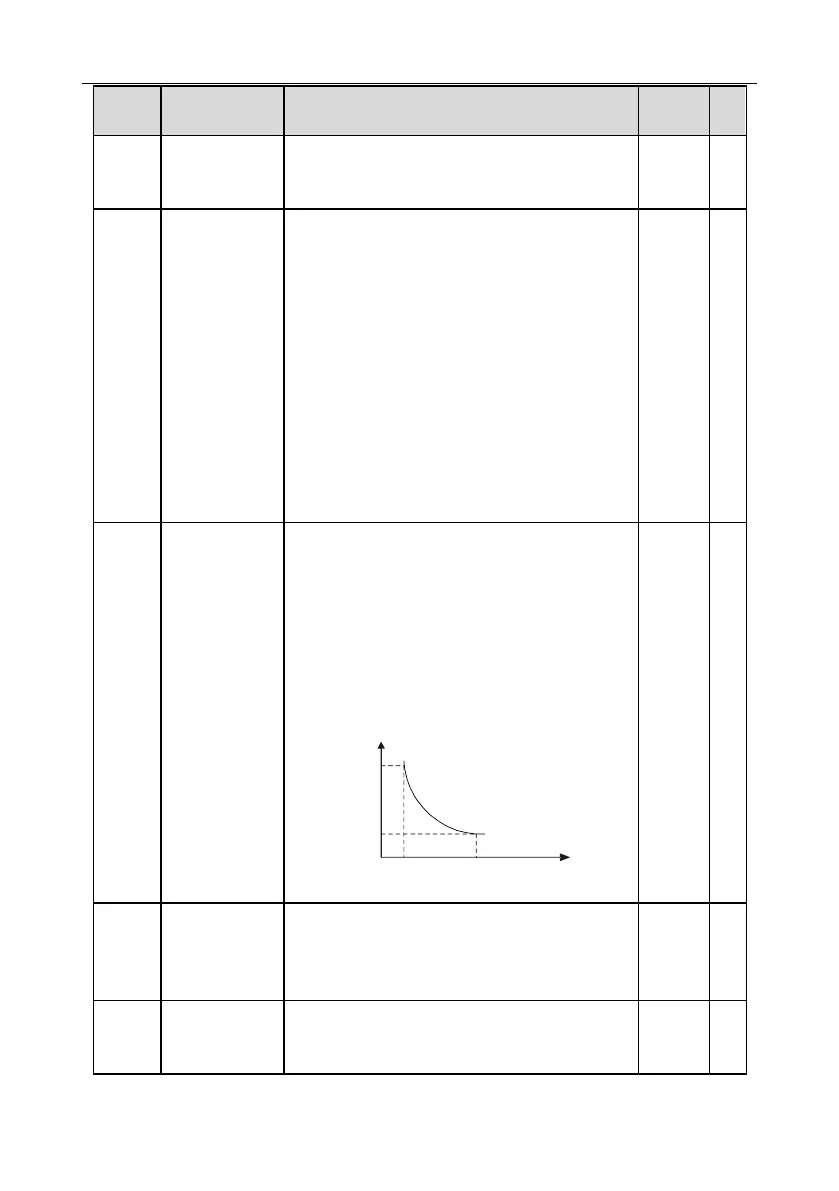

Motor overload multiples M=Iout/(In×K)

In is rated motor current, lout is inverter output

current, K is motor overload protection coefficient.

The smaller the K, the larger the value of M, and the

easier the protection.

M=116%: protection will be applied when motor

overloads for 1h; M=200%: protection will be applied

when motor overloads for 60s; M>=400%: protection

will be applied immediately.

1m

1h

116

%

200%

Time t

Motor overload multiple

Setting range: 20.0%–120.0%

Power display

calibration

coefficient of

motor 1

This function adjusts the power display value of

motor 1 only, and it does not affect the control

performance of the inverter.

Setting range: 0.00–3.00

Parameter

display of motor 1

0: Display as per motor type; under this mode, only

parameters related to current motor type will be

displayed.

Loading...

Loading...