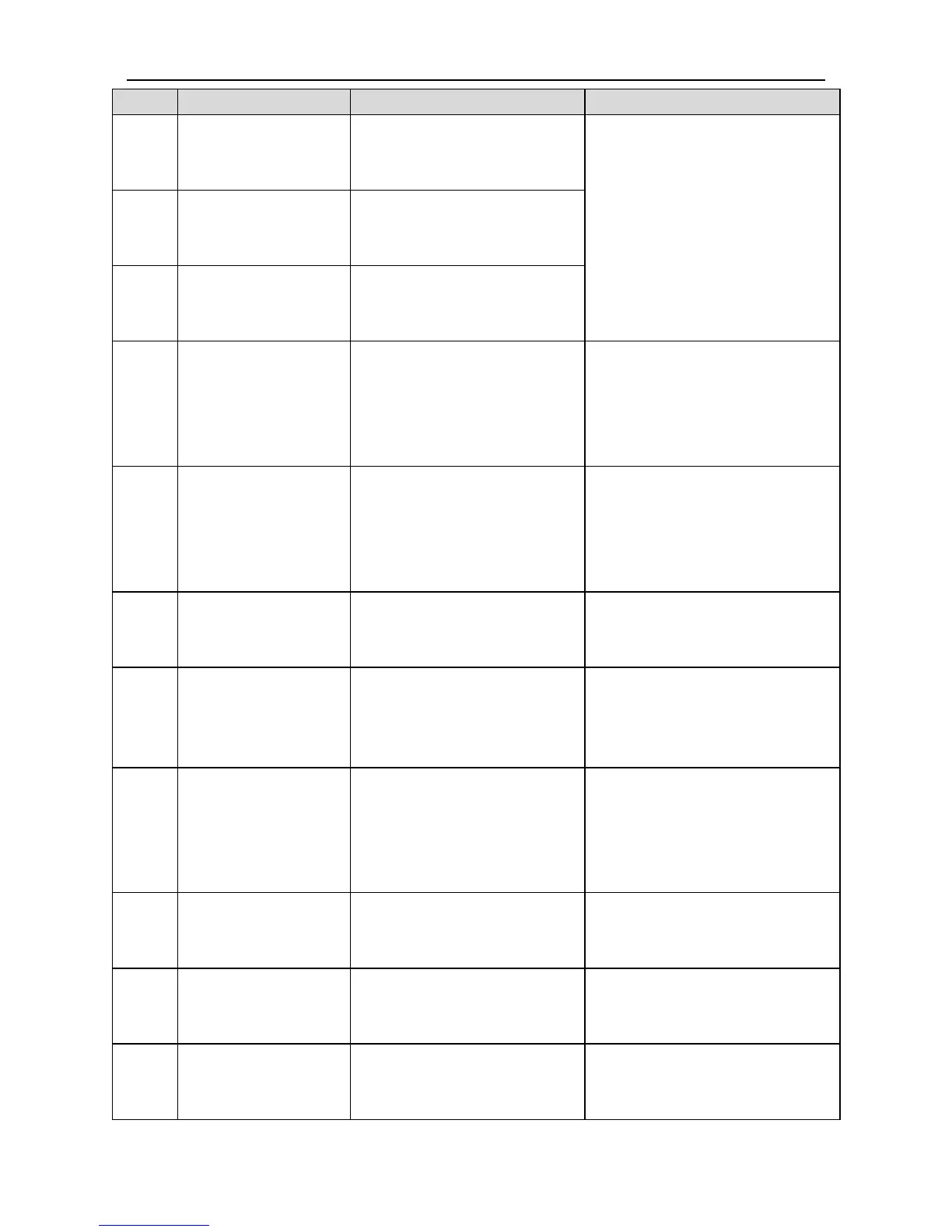

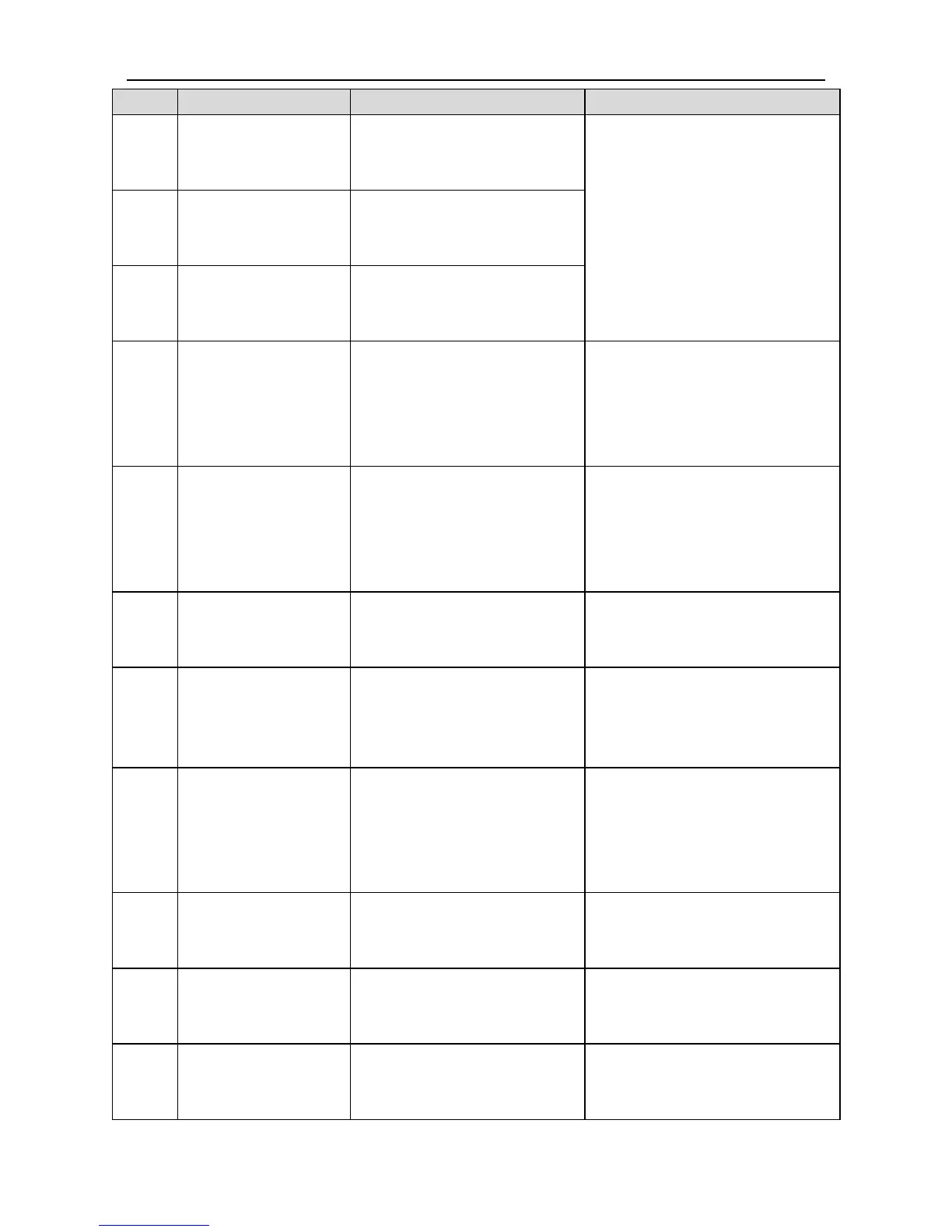

SV-DA200 series AC servo drive Faults and solutions

-258-

Analog input overvoltage

fault– Analog input 1

The voltage inputted to analog

input 1 port exceeds the setting

value of P3.22.

1. Set P3.22, P3.25, P3.75 correctly;

2. Check the terminals wiring;

3.Set P3.22, P3.25, P3.75 to 0 to

disable the protection function.

Analog input overvoltage

fault– Analog input 2

The voltage inputted to analog

input 2 port exceeds the setting

value of P3.25

Analog input overvoltage

fault– Analog input 3

The voltage inputted to analog

input 3 port exceeds the setting

value of P3.75

EEPROM fault–

Read-write fault

1. The data stored in data storage

area is damaged when reading

data from EEPROM

2. There is interference to

EEPROM write operation

1.Try again after repower on;

2. If the problem reoccurs for many

times, change the drive.

EEPROM fault– data

check fault

1. The data read from EEPROM

when power on is different from

that during writing;

2. The drive DSP software

version updates.

1. Reset all parameters;

2. If the problem reoccurs for many

times, change the drive.

Hardware fault– FPGA

fault

1. Repower on;

2. If the problem reoccurs for many

times, change the drive.

Hardware fault–

Communication card

fault

External communication card

fault

1. Repower on

2. If the problem reoccurs for many

times, change the communication

card

Hardware fault– Ground

short circuit fault

During the earth test after power

on, one of motor cables V, W is

short-circuited to the ground

1. Check the connection of the motor

cables;

2. Change the motor cable or test

whether the motor insulation aging

or not.

Hardware fault– External

input fault

This fault occurs when the digital

terminal configured as external

fault input function acts.

1. Clear the external fault input and

enable fault clearance;

2. Repower on the drive

Hardware

fault–Emergency stop

fault

This fault occurs when the digital

terminal configured as

emergency stop button acts.

1. Clear the emergency stop input

and enable fault clearance;

2. Repower on the drive

Hardware fault– 485

communication fault

Strong EMI of 485 communication

circuit causes drive serial

communication alarms

1. Use twisted shielded pairs for 485

communication;

2.Wiring communication cables and

Loading...

Loading...