17

f Check the correct funconing of automac venng de-

vices, eventually installed;

f Close the radiators venng devices as soon as water ows

out of them;

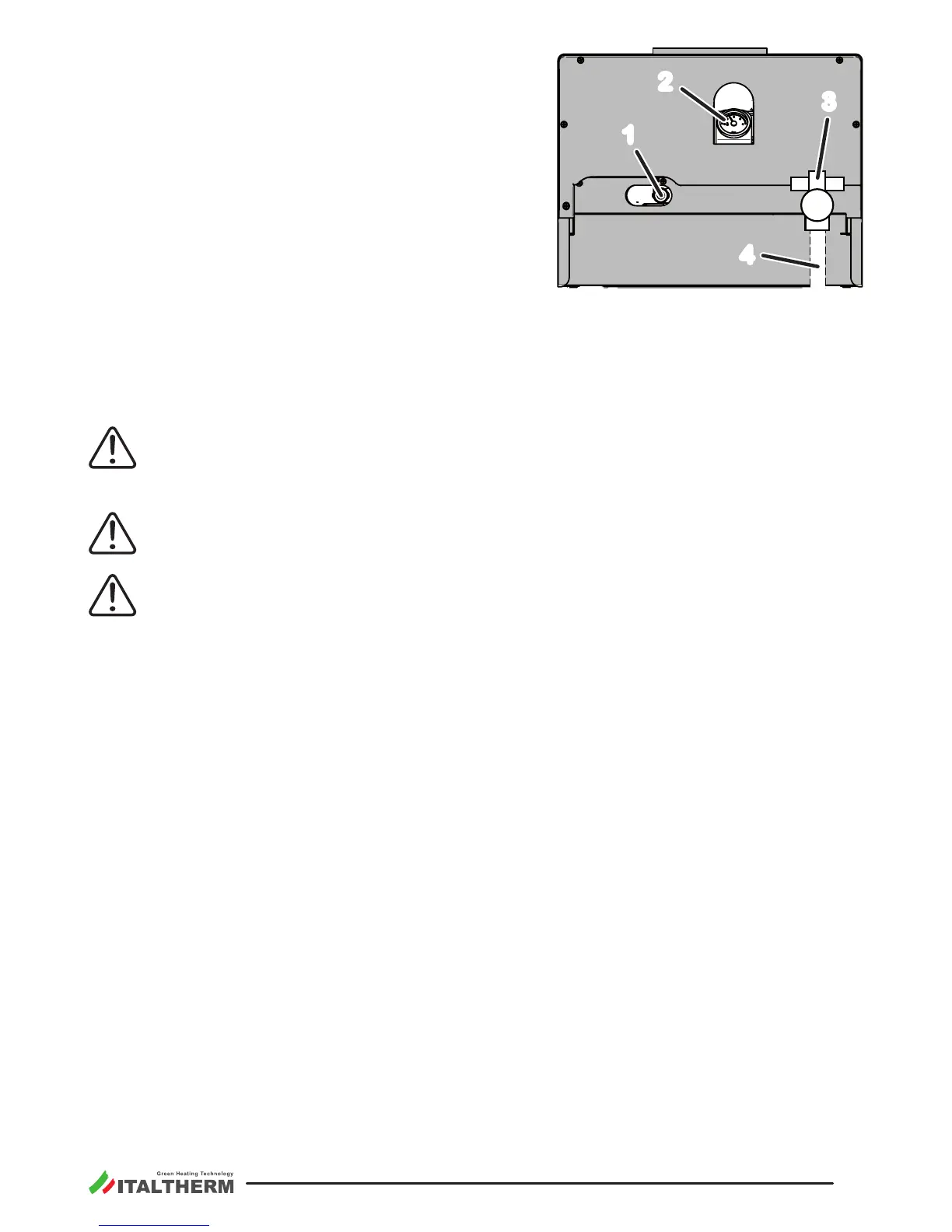

f Make sure, by reading the pressure gauge 2, that the pres-

sure reaches the opmal value of ;

f Close the water supply valve 1 and bleed each radiator

again;

f Repeat the venng and pressurizaon operaons unl

the air is completely purged from the system.

Due to various installaon possibilies, the gas cock 3 supplied with the original Connecons Kit has a

simple male Ø ½” connecon, facing the rear of the boiler. The gas pipe 4, upstream the gas cock 3, should

be supplied by the installer.

-

-

The gas connecon, as generally the boiler installaon, must be done by qualied personnel as

prescribed by the regulaon in force, because a faulty gas connecon could lead to re, explosion

and other very serious damages to persons, animals and objects. The manufacturer cannot be

held responsible for any damage arising from that situaon.

f Verify what follows:

• cleaning of all system gas pipes in order to avoid the presence of work residuals that could com-

promise the correct boiler funconing;

• gas line and ramp conformity with laws and rules currently in force;

• internal and external ghtness of the gas system and connecons;

• supply pipe must have a secon greater than or equal to the boiler one;

• supply gas must correspond to the one for which the boiler has been set: otherwise, it's manda-

tory to ask to qualied personnel to set the boiler for the correct gas type;

• an intercepon valve must be installed upstream the appliance.

f Open the meter valve and purge the air that is inside the system pipes (including all the appliances).

00006 00

2

4

1

3

Loading...

Loading...