SERVICE MANUAL FOR SXG323&326

22

INSPECTION AND MAINTENANCE OF MAJOR PARTS

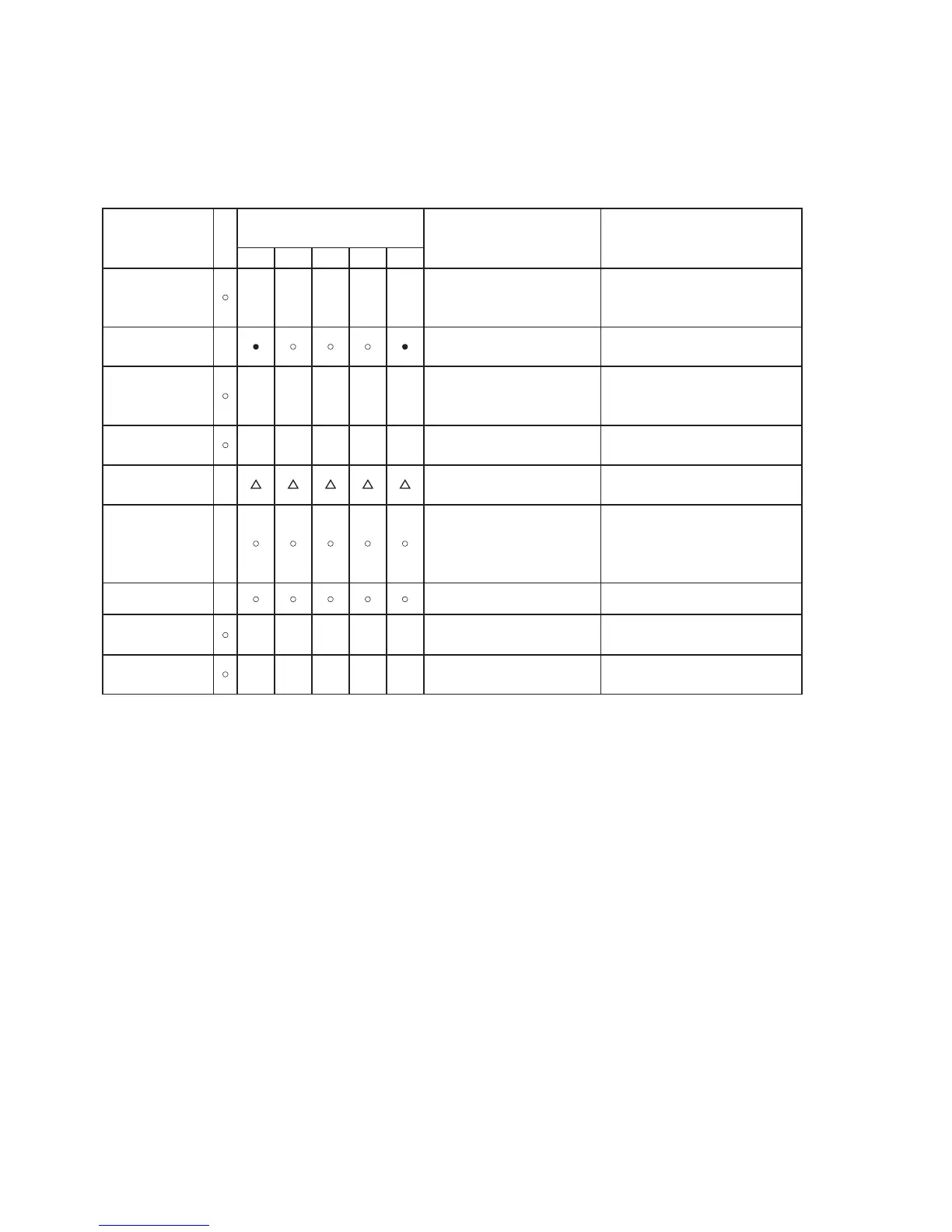

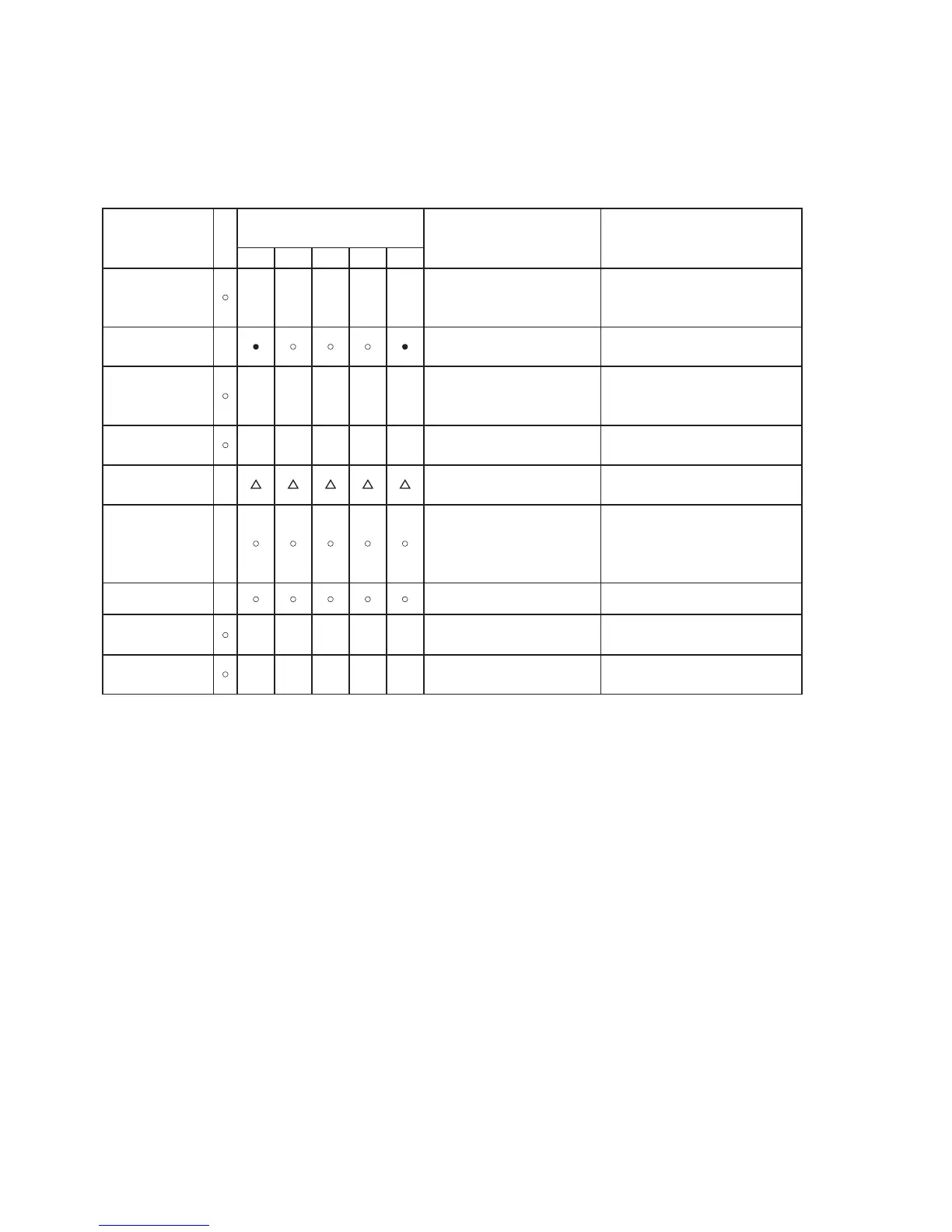

8. PERIODICAL INSPECTION TABLE

ۑ:Inspection, replenishment, and adjustment ڹ: Cleaning and washing

ە: Replacement

Important:

• Above mentioned service intervals should be used as reference criteria. If working conditions are

harder, earlier service is recommended.

• When special technology and special tools are required, consult your dealer.

Inspection and servicing

intervals (hours of operation)

Check points

50 100 150 200 250

Intervals after that Judgement criteria

Deformed, broken, worn,

and cracked ones should

Blade

be replaced.

Bevel gear case Replace after initial 50 h. and Maintain the specified

(LH) and (RH) then after every 200 h. level.

Spring coil clearance Belt tension

Roller and gauge They should turn

wheels smoothly.

There should be no grass

Belt cover inside Clean alter every 50 h.

or dust accumulated.

Criteria for replacement:

· Deep crack over half the

thickness of belt.

Belt Clean after every 50 h.

· Worn out side wall canvas

Greasing points Grease up after every 50 h.

Bolls and nuts There should be no loose ones.

There should be no lost or

Pins and crimps

deformed ones.

Loading...

Loading...