CHAPTER 4. ENGINE

61

4

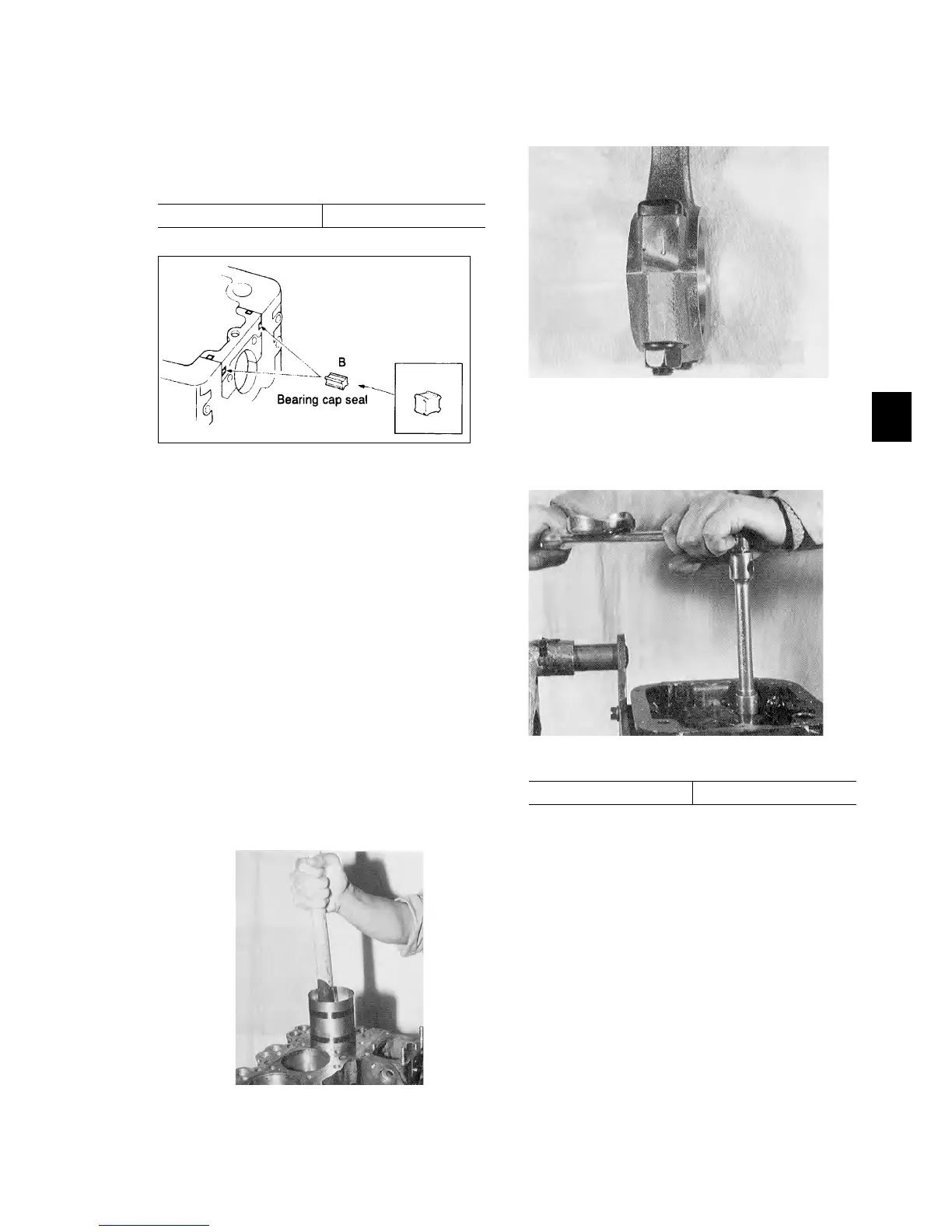

(4) Then install bearing cap seals (B). Drive them in

until they subside 0 - 0.3 mm (0 - 0.012 in.) from

the cylinder block end. Fill the gaps with sili-

cone compound. Tighten the journal bearing cap

to the specified torque.

Fig. 4-95

3.3.7. INSTALLATION OF PISTON/CON-NECT-

ING-ROD ASSEMBLIES

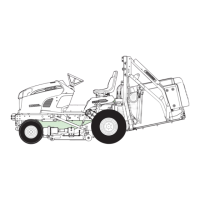

•Install bearings on the connecting-rod big end

and bearing cap with the bearing projections

seated securely in respective notches in the big

end and bearing cap. Apply engine oil to the

bearing surfaces.

•Clean the cylinder bores and crankshaft, and

apply engine oil to them.

• Set the crankshaft at BDC.

• Turn the front mark on the piston head towards

the front and make sure that the piston ring gaps

are 120°apart from each other. Then insert the

piston/connecting rod assembly, compressing the

piston rings with a piston ring compressor, into

the cylinder until the connecting rod bearing

comes into contact with the crankpin.

Fig.4-96

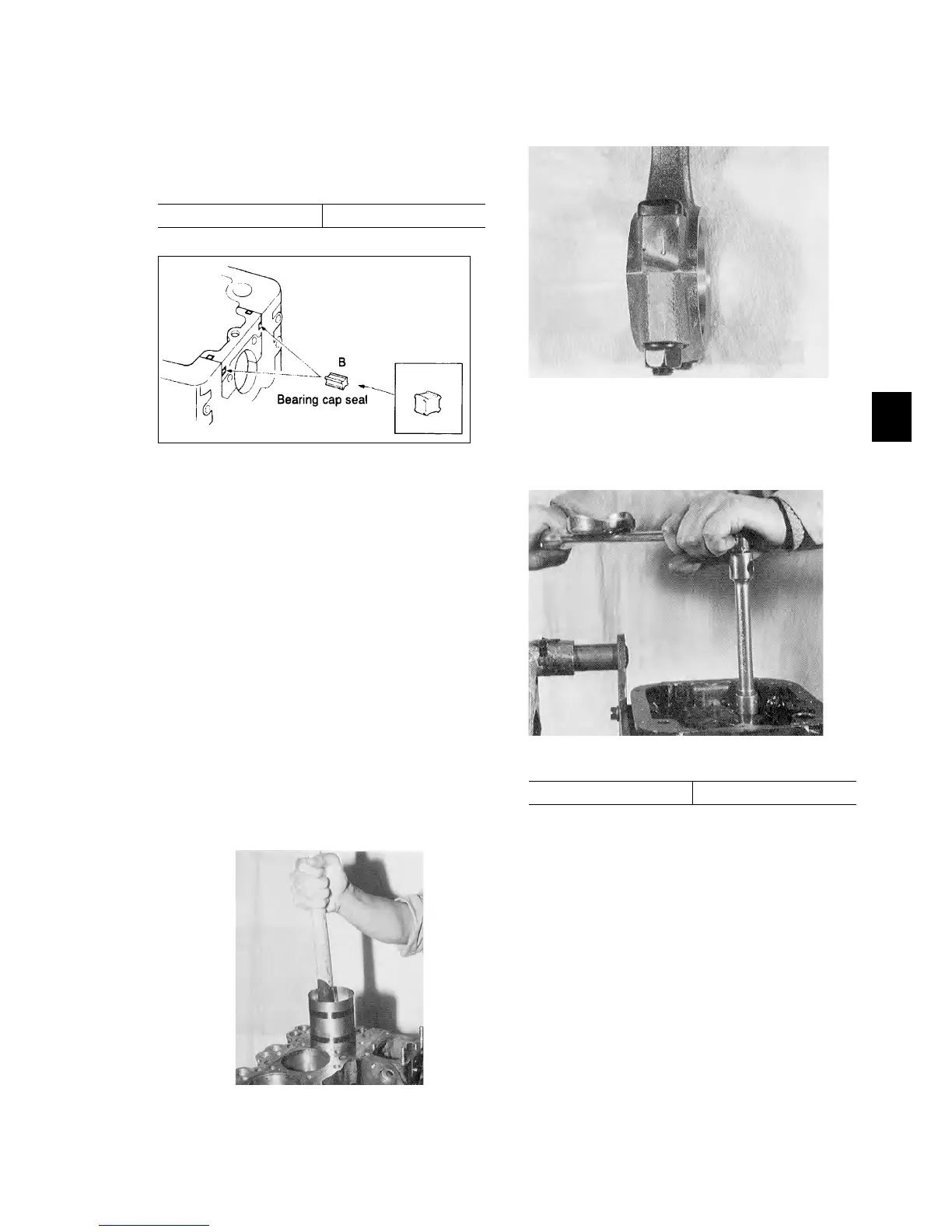

• Install the connecting rod bearing cap having the

same number that the connecting rod has.

Fig. 4-97

•Tighten the connecting rod bearing cap to the

specified torque.

Fig. 4-98

The crankshaft should turn smoothly.

Specified torque:

4.5 - 5.5 kgf・m

Specified torque:

2.7 - 3.3 kgf・m

Loading...

Loading...