Page 11

ENGLISH

Jandy

®

Pro Series VS FloPro™ Series Variable-Speed Pump

|

Installation & Operation Manual

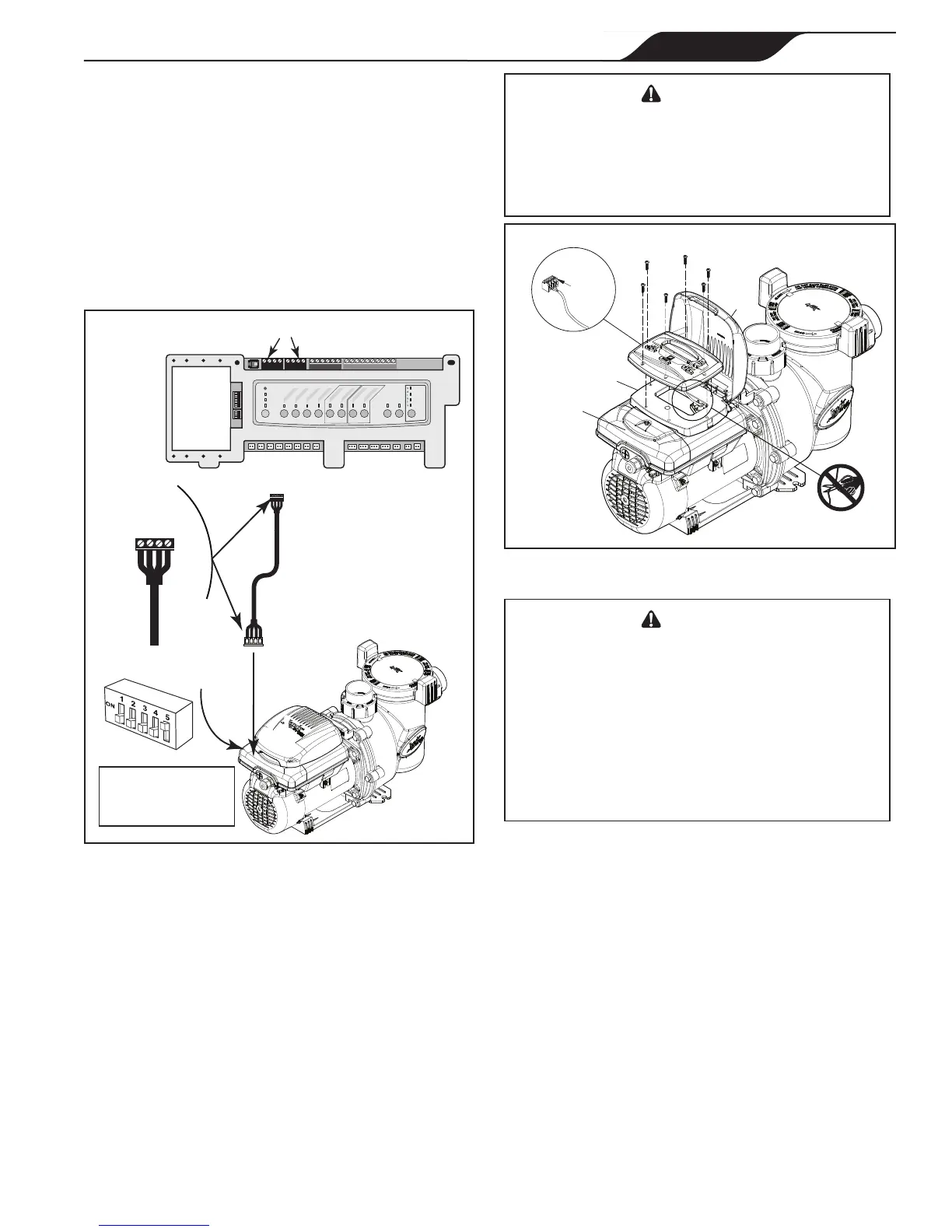

7. Connect the other end of the cable to an RS-485

connector on the AquaLink

®

RS (or multiplexer

interface board), matching wire colors with

connector positions as follows: 1-red, 2-black,

3-yellow, and 4-green. See Figure 7.

8. Restore power to the VS-FHP1.0 pump and verify

the operation of the controller.

9. Refer to the appropriate manual for set up and

operation of the pump: AquaLink RS Owner’s

Manual, 6593, AquaLink PDA Owner’s Manual,

H0572300, or AquaLink Z4 Owner’s Manual,

H0386600.

Variable-Speed

Pump

4321

RED

BLACK

YELLOW

GREEN

RS485

Cable

BLACK

YELLOW

RED

GREEN

Connect to

AquaLink RS

RS-485 Connector

(or Multiplexer

Interface Board)

S1

S2

RESET

SERVICE

TIME OUT

FILTER PUMP

AUX 1

AUX 2

AUX 3

AUX 4

AUX 5

AUX 6

AUX 7

RS6 & RS8 ONLY

RS8 ONLY

HEATER

SOLAR

POOL MODE

SPA MODE

SPA DRAIN

SPA FILL

AUTO

654321

10 9876 54321

4321

4321

AquaLink

®

RS RS-485 Connectors

5-Position

DIP Switch

200 ft (61 m)

max install distance

for communication

Figure 7. Wiring AquaLink RS Controller or

AquaLink PDA to VS-FHP1.0 Pump

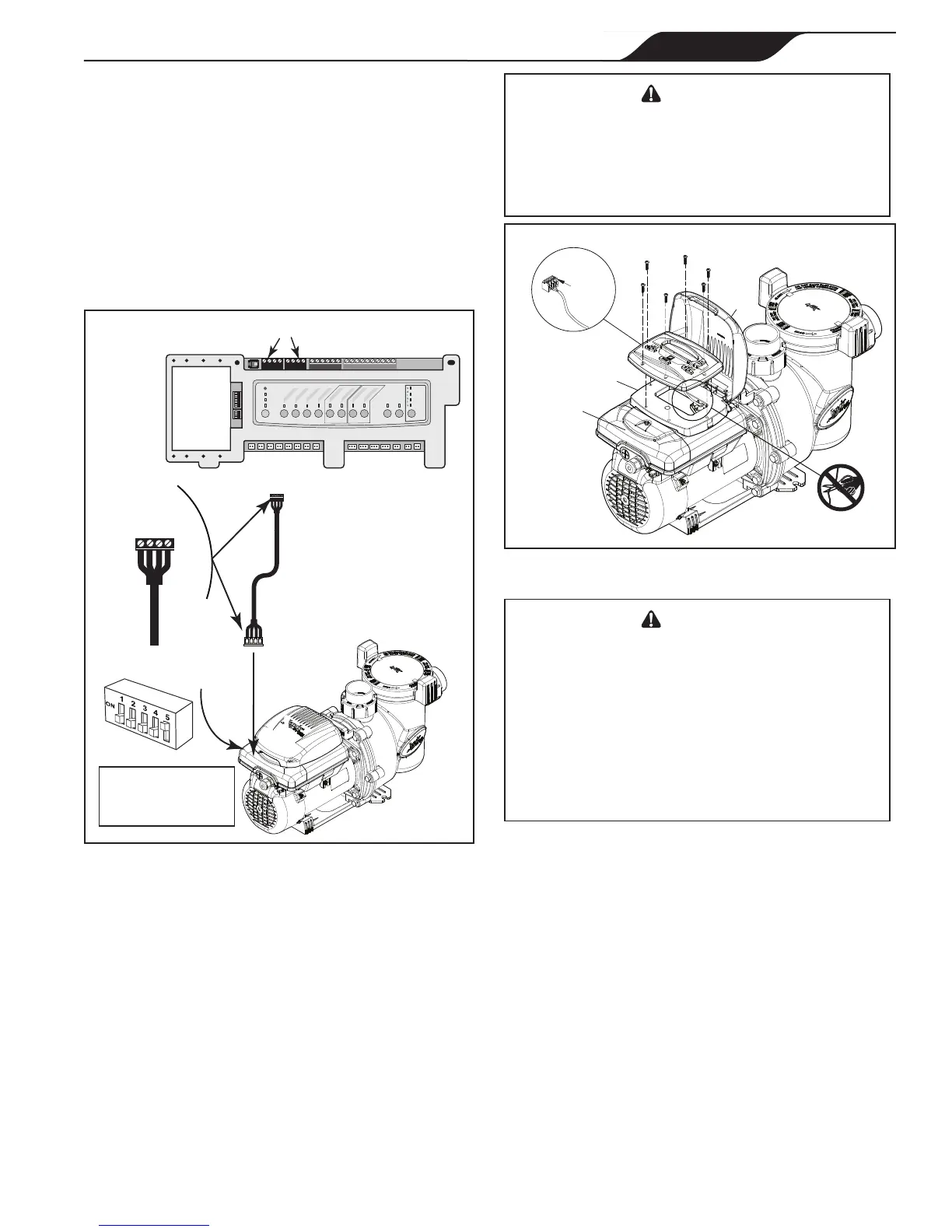

VS-FHP1.0 Remote Mounting

The variable-speed controller may be remote mounted

onto a vertical surface that is protected from the

elements.

Follow the directions carefully to maintain the ability

to reinstall the variable-speed controller onto the VS-

FHP1.0 Pump. Reverse these instructions to complete

the reinstallation. See Figure 8.

WARNING

ELECTRICAL SHOCK HAZARD

Turn off all switches and the main breaker in the variable-

speed pump electrical circuit before starting the procedure.

Failure to comply may cause a shock hazard resulting in

severe personal injury or death.

Controller Rear

Loosen

to remove

(x4)

Pump

Motor

Cover

RS-485 Cable

DO NOT CUT

Controller

Base

Access Cover

Figure 8. Disconnect Variable-Speed Controller

from VS-FHP1.0 Pump

WARNING

When determining routing and protection for the

variable-speed controller cabling, ensure that all

National Electrical Code

®

(NEC

®

) and all local code

requirements are met. NEC code requirements

prohibit the routing of signal cables in conduits or

raceways that are used for branch, feeder, or service

conductors. NEC also provides direction for building-

to-building routing of signal cables, with regard to

lightening protection.

At the VS-FHP1.0 pump:

1. Remove power from the VS-FHP1.0 pump by

disconnecting the high voltage lines or by opening

any breaker to which the VS-FHP1.0 pump power

is connected.

2. Lift up the controller cover on its hinges to access

the variable-speed controller.

3. Remove the six (6) screws to disconnect the

variable-speed controller from the controller base

on the VS-FHP1.0 Pump motor.

4. Detach the RS-485 cable connecting the variable-

speed controller user interface to the controller base

on the motor. Do not over extend the cable when

raising the controller away from the motor.

5.

Unscrew the four (4) connector terminals and

disconnect the wires of the motor cable assembly.

Note: Do not cut the cable, or you will lose the ability to

return to the default factory configuration.

Loading...

Loading...