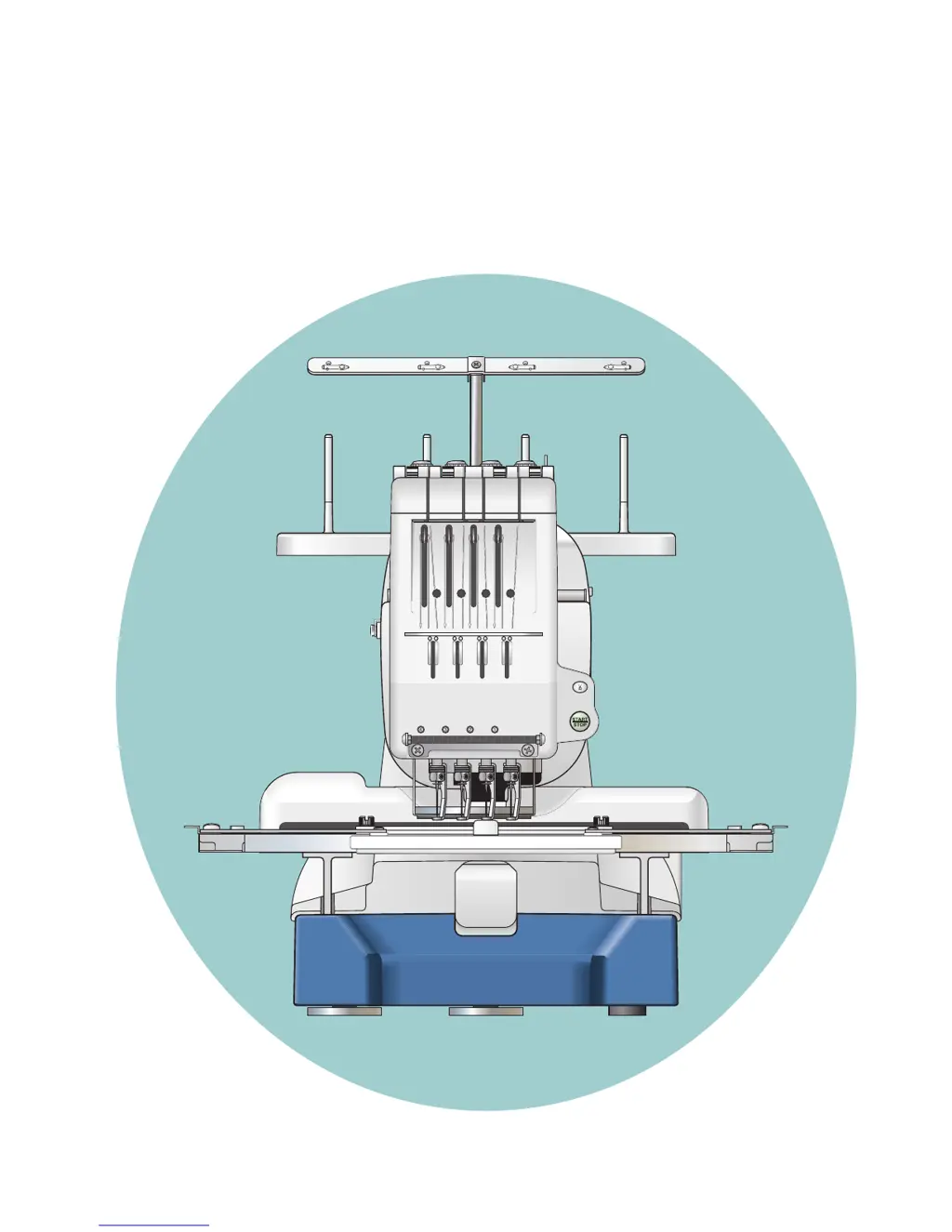

Why my Janome Sewing Machine does not work?

- RRiley Williams PhDAug 27, 2025

Your machine may not be working because: * It is not plugged in. * A thread is caught in the hook race. * The clutch knob is pulled away for bobbin winding. * The bobbin winder spindle is in the winding position.