4. ADJUSTMENTS

DANGER: When all blades on the rotor have been worn and the rotor

adjusted towards the shearbar, it MUST be adjusted back again

before new blades are mounted. Otherwise there is a risk that

the new blades collide with the shearbar when the rotor is

turned.

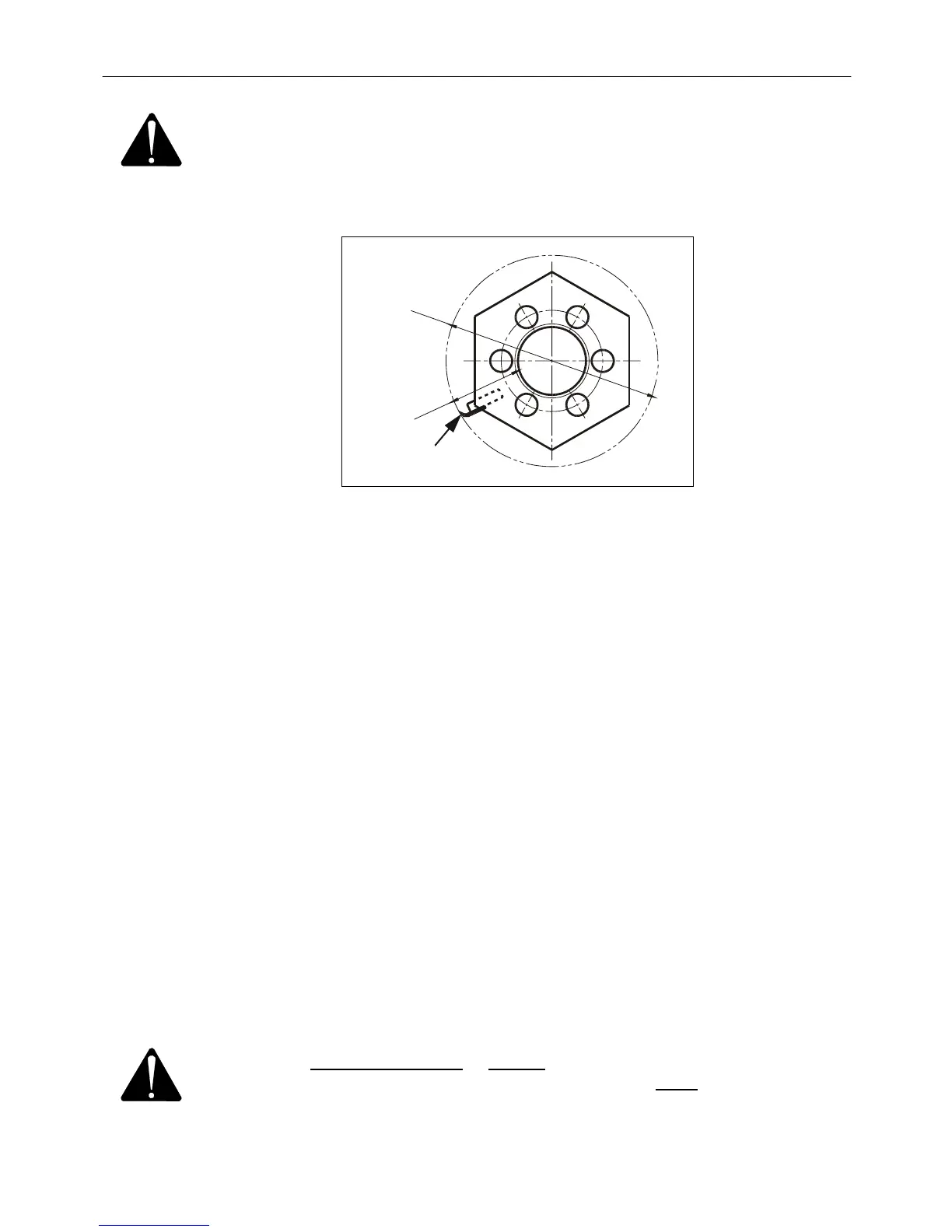

PR11-0470

1

5

6

Ø

4

8

0

Fig. 4-11

Fig. 4-11 When mounting new blades they must be pulled out so that the outer diameter on the

rotor is 480 mm (from rotor tube to blade point = 156 mm).

GRINDING

Adjustment of the PTO drive shaft for the rotor to or from grinding position,

respectively, may only take place when the machine has been stopped and the

rotor has come to a complete standstill. The rotor may only rotate when the

grinding device is in grinding position.

Check before grinding:

- that the grindstone is undamaged.

- that the device is easily sliding back and forth.

- that the device is parallel with the rotor.

The grinding device is correctly adjusted from the factory and therefore there is

normally no need for adjustment, but if it has been dismounted adjustment can be

made at the oblong holes of the lateral guides. The bolts must be tightened firmly

after the adjustment.

The stone is fed by turning the handle.

Normally you should grind the blades once a day – but avoid too much grinding.

CAUTION: Protect your eyes – always use safety glasses when grinding.

The guard above the grinding device must be closed while

grinding.

PIGB-138X-02 FC 855 0410

- 39 -

Loading...

Loading...