6. MAINTENANCE

FRICTION CLUTCH

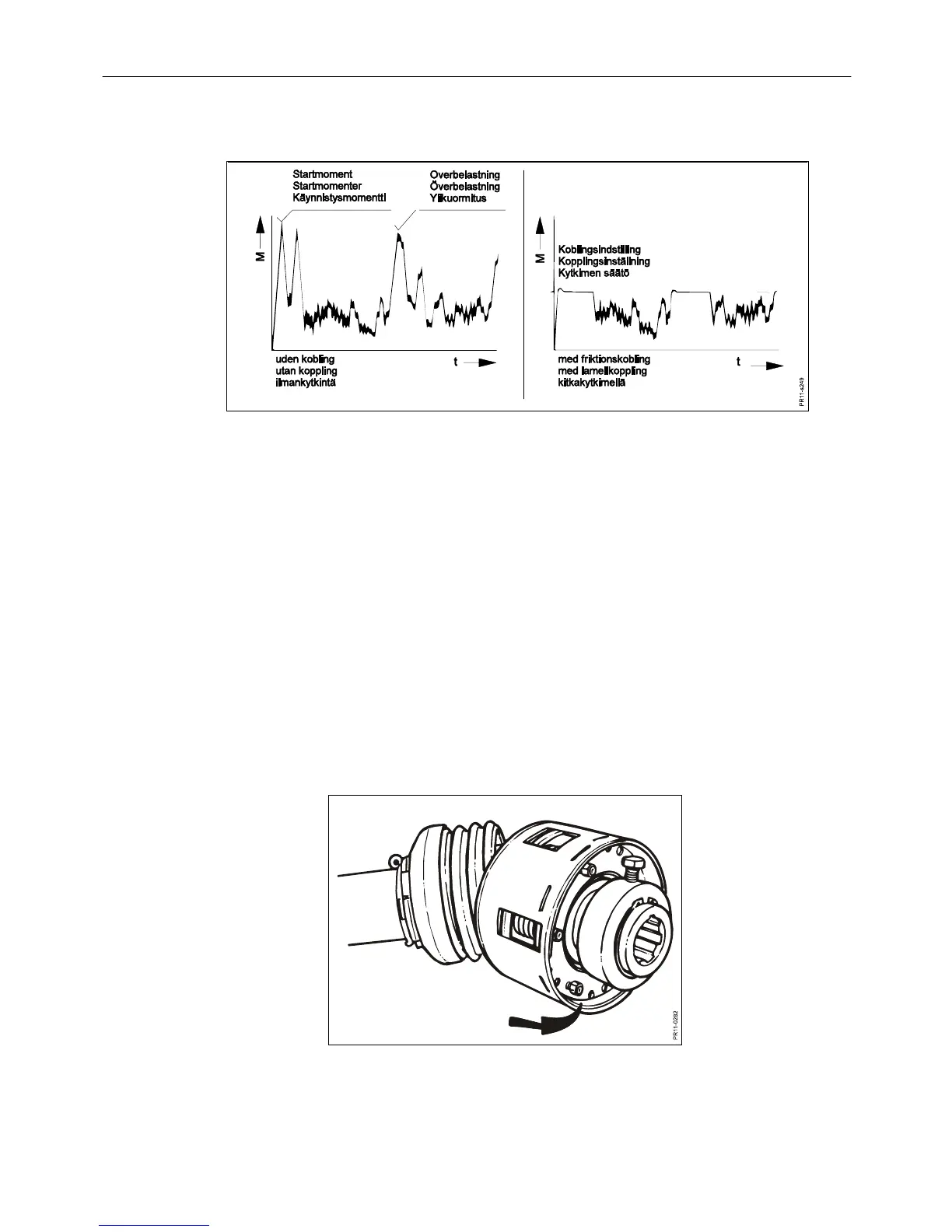

Fig. 6-3

Fig. 6-3 In order to ensure a long life for your tractor and machine, the machine is delivered

with a friction clutch on the PTO drive shaft from the bevel gearbox to the machine

and on the driving mechanism for the feed rollers. The figure illustrates how the

clutch protects the transmission against high torque peaks and at the same time is

capable of transmitting the torque while it is in function (slips).

The auger is also fitted with a friction clutch as described in the section PICK-UP in

chapter 4 "ADJUSTMENTS".

The friction clutches must be maintained at regular intervals. At the same time, the

clutches must be checked if they have not been in operation for some time. This

especially applies after winter storage before the machine is used for the first time in

the season.

Maintenance of the friction clutch on the PTO drive shaft:

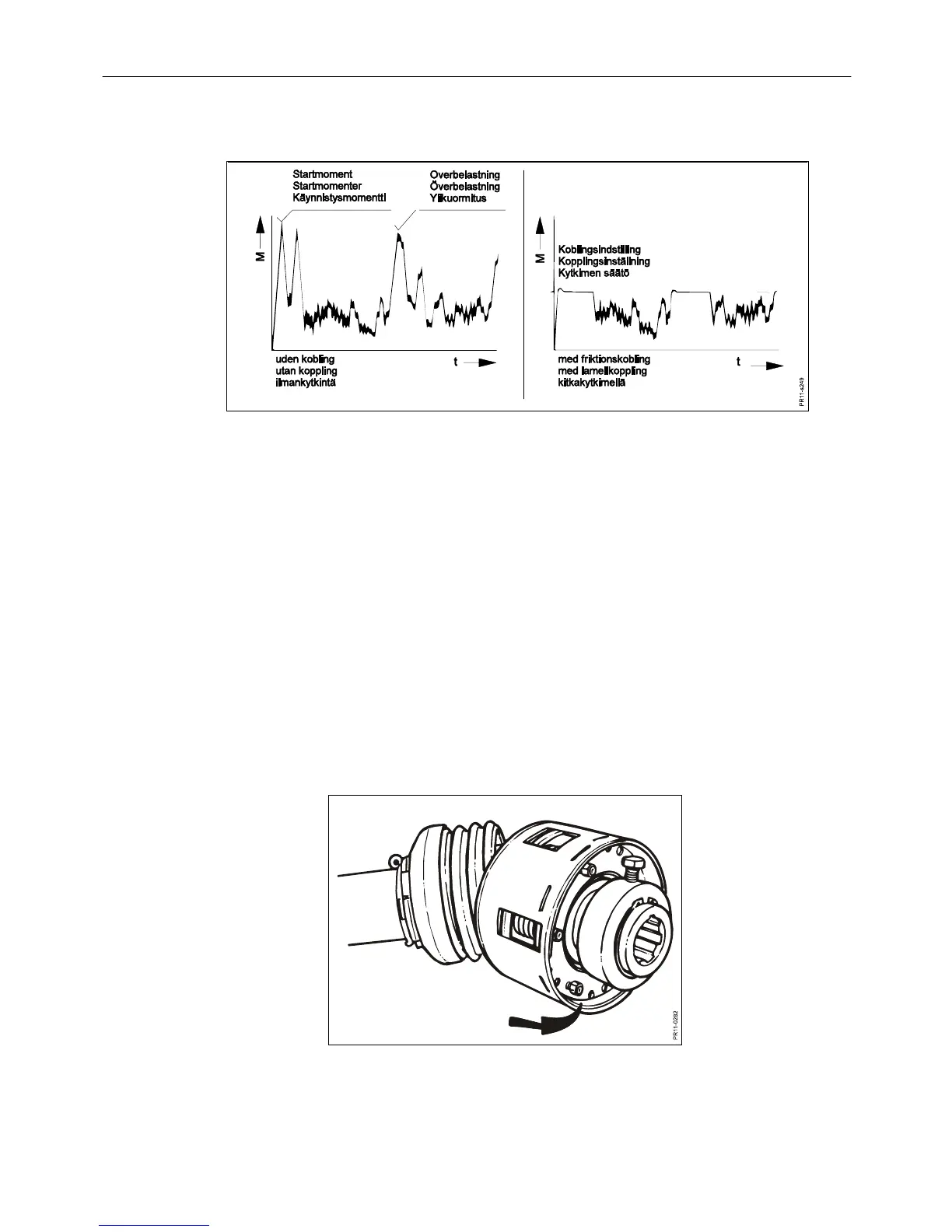

Fig. 6-4

Fig. 6-4 Before the start of a new machine and after a long period of standstill, e.g. winter

storage, the clutch is "aired" in the following way:

PIGB-138X-02 FC 855 0410

- 50 -

Loading...

Loading...