70

Operator’s Manual

Operations

QUADRIGA 1000/BB

5.1-1

5.1-2

4.1-3

2

1

OK

5.1 Wheel Lifter

WARNING: IF THE WHEELS ARE HEAVY USE THE

LIFT DEVICE

5.1.1 Using the Wheel Lifter

Should the user require it, the machine is provided with

a lift device that will raise the wheel or just the rim from

the ground to a suitable working height.

This will prevent any excessive effort or potentially

harmful movements on the part of the operator.

Figure 5.1.1-2

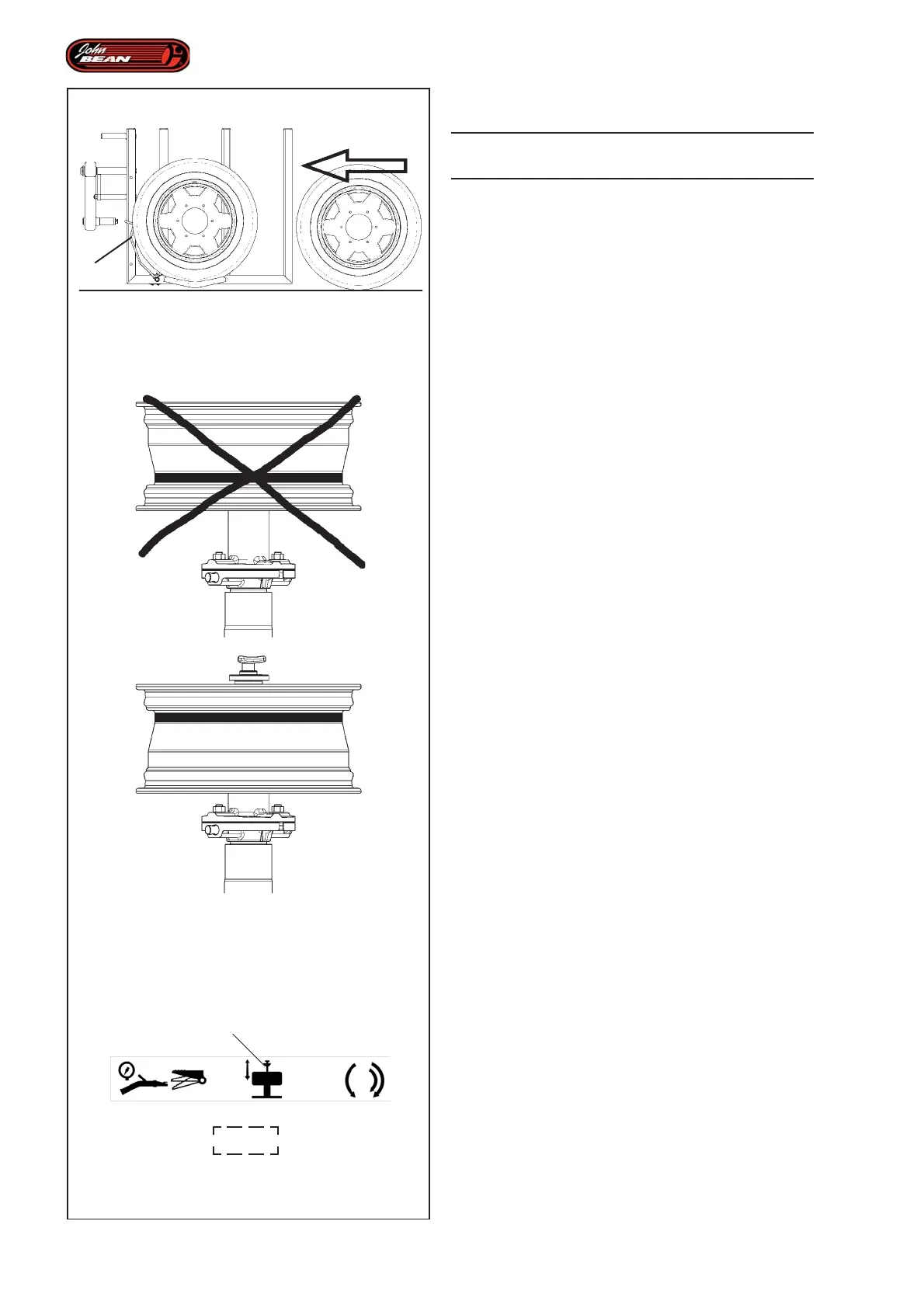

WARNING:

ONCE THE WHEEL HAS BEEN MOUNTED ON THE

FLANGE, THE RIM DROP CENTER MUST ALWAYS

BE POSITIONED HIGH, NEXT TO THE MOUNT/

DEMOUNT TOOL.

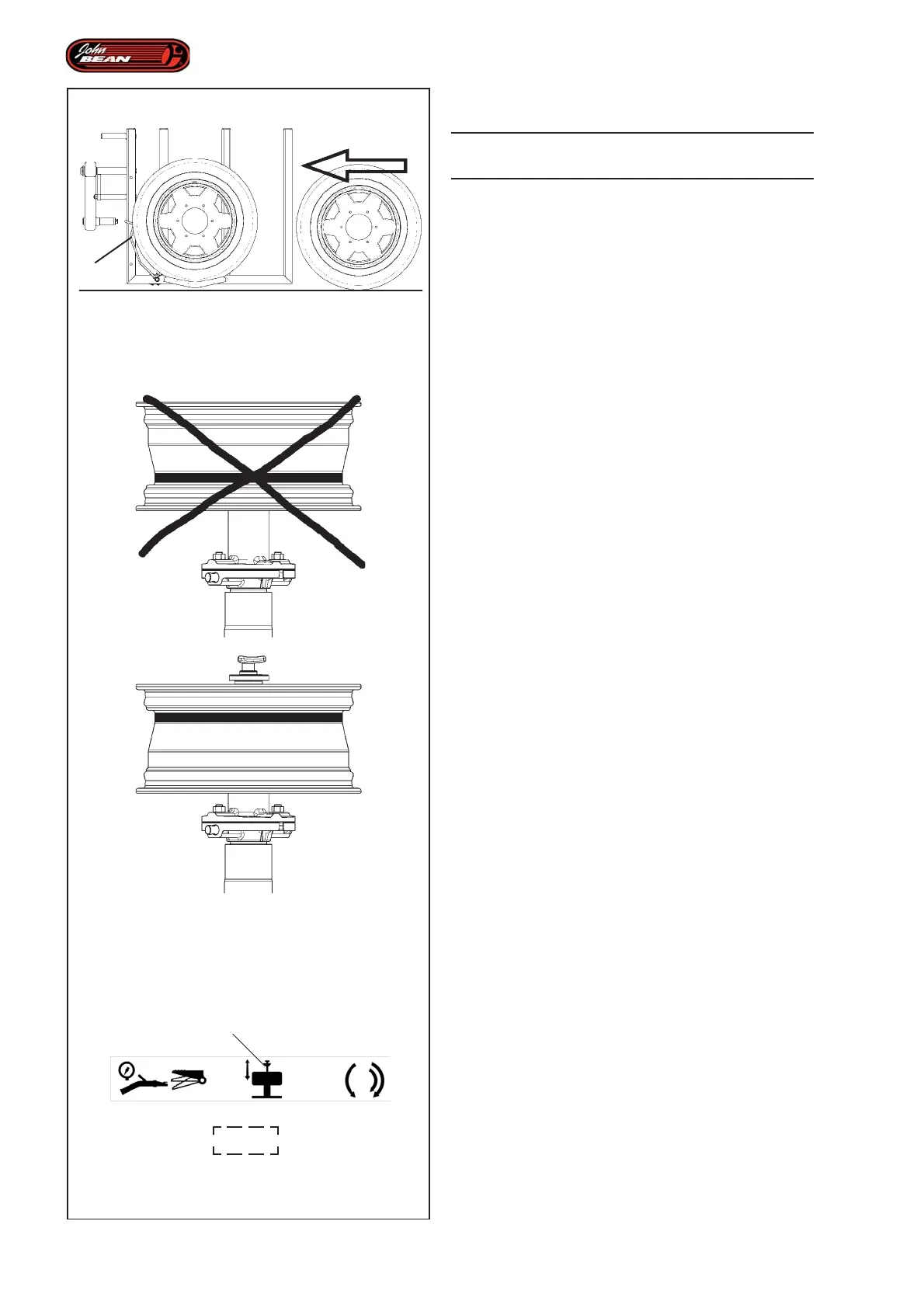

5.1.1.1 Loading the wheel

To position the wheel on the front lifter, proceed as

follows:

• Check that the wheel holder flange is free.

• Position the grip pin arm in the closed position

(towards the centre of the flange).

• Check that MANUAL Mode is selected.

• Activate the command (2, Fig. 4.1-3) to move the

rim clamping rod into the right back position.

• Move the wheel up to the front lifter so that the rim

drop center is facing the outside of the machine.

• Load the wheel by rolling it onto the lift device (Fig.

5.1.1-1).

If the wheel positioned on the lift device has an external

diameter that is large enough to activate the Wheel

Sensor Arm (1, Fig. 5.1.1-1), the Load wheel onto Wheel

Holder Flange operation will be enabled and the

movement will be performed automatically by the

machine.

Note: Wheels with small diameters or rims only

have a low weight and as a result of their

size they may not activate the Wheel

Sensor Arm (1, Fig. 5.1.1-1). So these

parts should be located manually on the

tire changer wheel holder flange.

Loading...

Loading...