74

Operator’s Manual

Operations

QUADRIGA 1000/BB

5.1-4

4.1-3

5.1-5

1

2

3

2

4

5

5

5.1.2 Clamping - Unclamping the wheel

Note: In the case of wheels without a central hole

or with a hole that is unsuitable for

clamping, special adapters are available

as accessories; these allow the wheel to

be locked in place using the lug nut holes.

See the 'Accessories available on Request'

section.

Below is a list of the different types of non-standard

wheels that clamping kits are available for:

- REVERSE DROP CENTER WHEELS

- LARGE WHEELS (Van wheels)

- WHEELS WITHOUT A CENTRAL HOLE

5.1.2.1 Clamping the wheel

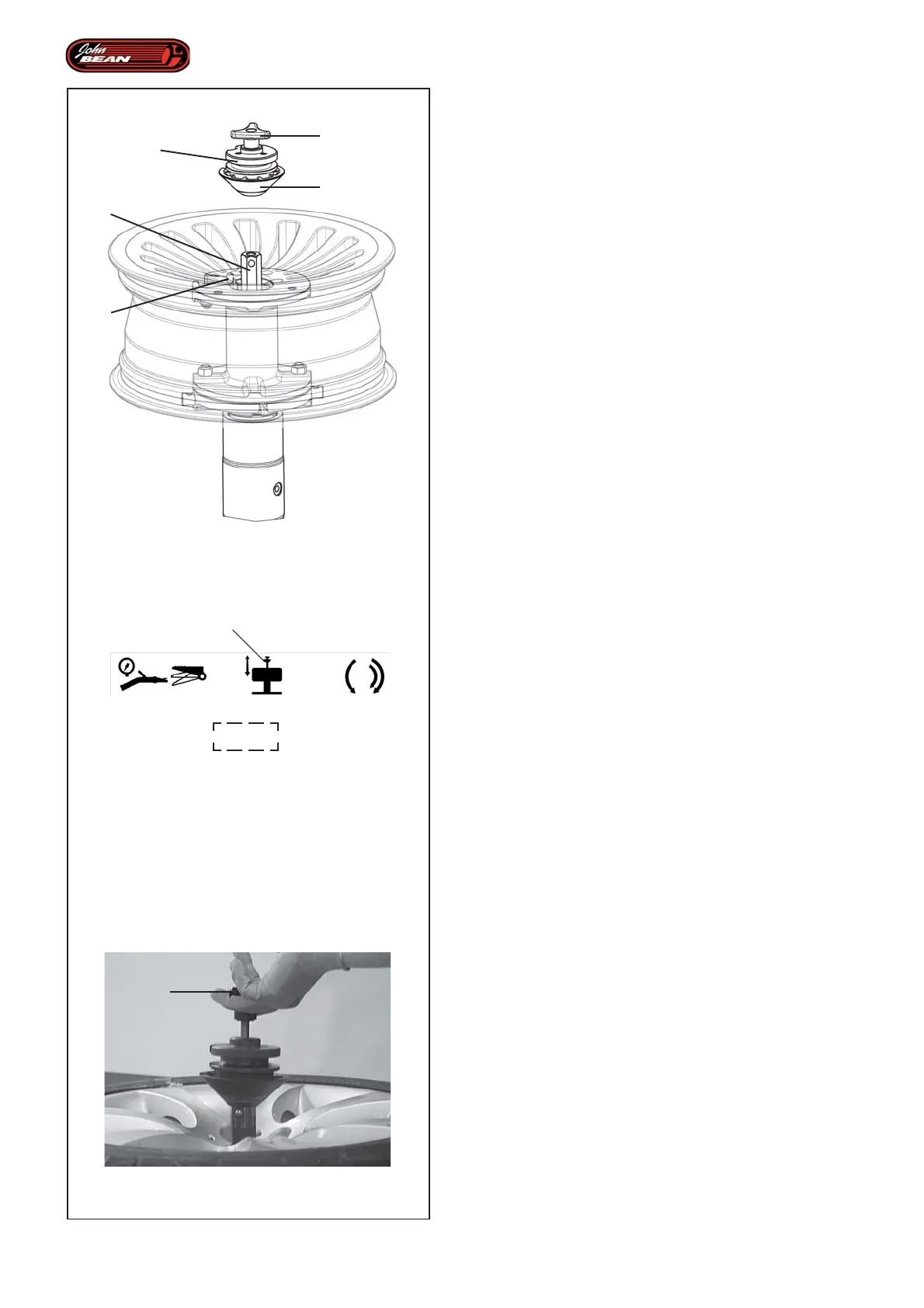

Figure 5.1.3-1

To complete the wheel or rim loading operation on the

Wheel Holder Flange, proceed as follows:

• Rotate the rim on the flange until the grip pin 1 is

brought inside one of the securing holes on the wheel.

• Check that the machine is in Manual Mode.

• Use the control (2, Fig. 4.1-3) to lift the hexagonal

rod 2.

• Prepare the clamping unit 3, with the cone 4, required

for the hole diameter and the type of rim you are

clamping.

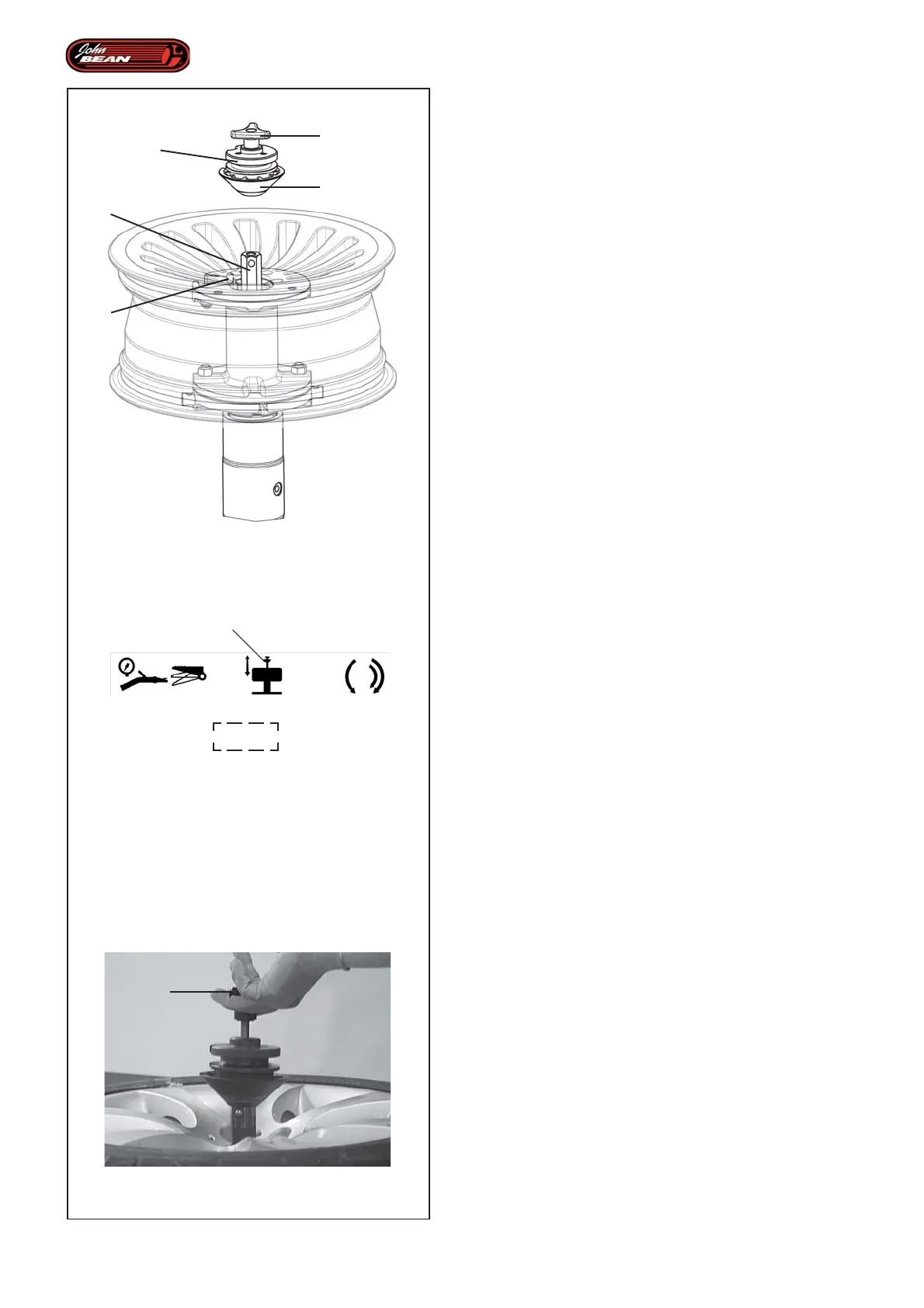

• Insert the complete clamping tool onto the hexagonal

rod 2.

Note: Before proceeding check that the tool is

gripping as it should be.

• Clamp the rim using the clamp command (2, Fig.

4.1-3).

The wheel is now locked in place and tire mount/demount

tasks can be carried out.

5.1.2.2 Unclamping the wheel

To unclamp the wheel:

• Check that the machine is in Manual Mode.

• Activate the pedal command (2, Fig. 4.1-3).

Note: Every time you press the Clamp/Unclamp

command pedal the hexagonal rod will

move in the opposite direction to the

previous one.

• Pull the knob (5, Fig. 5.1.3-1) upwards and remove

the Clamping Unit completely.

Loading...

Loading...