92

Maintenance

Operator’s Manual QUADRIGA 1000/BB

6.0-1

6.0-2

4

3

5

1

2

6

7

max

min

6.0 Maintenance

This tire demount unit will continue to provide maximum

working efficiency even after a long period of intensive

use as long as the operator carries out scheduled

maintenance as indicated below.

WARNING: BEFORE ATTEMPING ANY

MAINTENANCE OR REPAIRS THE MACHINE MUST

BE DISCONNECTED FROM THE ELECTRICAL

POWER SUPPLY AND THE COMPRESSED AIR

FEED LINE.

Every 6 months,

Arrange for the following to be carried out

• Check the various parts listed below for excessive

play and adjust if necessary (Call the technical service

center):

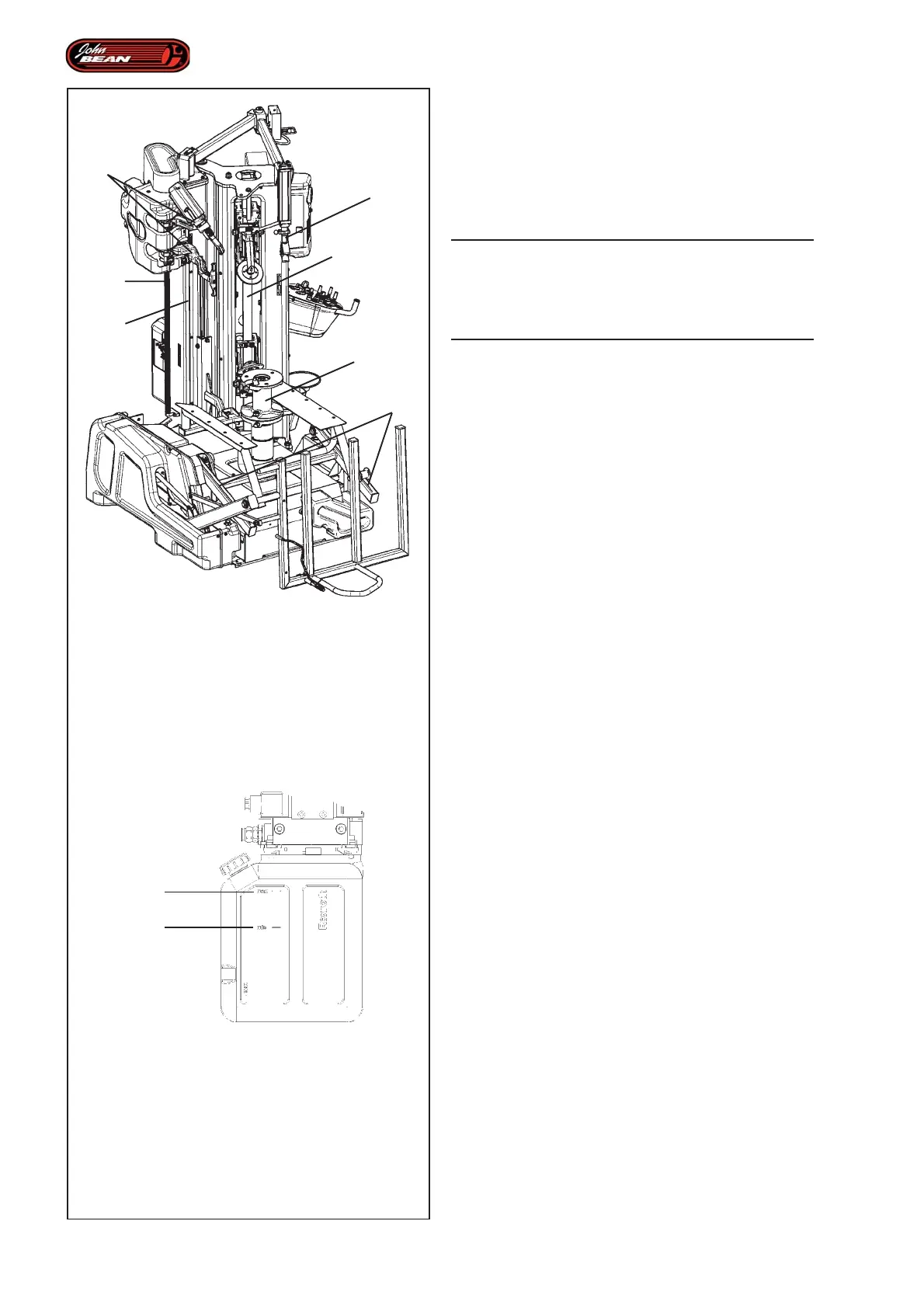

Figure 6.0-1

1) Wheel support.

2) Vertical activation bar on tools

3) Tool unit slide guides

4) Bead-breaker vertical slide guide

5) Lifter unit slide guides.

Every 4 months,

carry out:

• Removal of accumulated dirt with non-flammable

liquid detergent.

• Restoration, using a brush, of a suitable quantity of

oil for mechanical lubrication.

on the parts:

Figure 6.0-1

3) Tool unit slide guides

4) Bead-breaker vertical slide guide

5) Lifter unit slide guides

6) Automatic tool mobile parts and arms.

7) Bead pusher tool extraction rod.

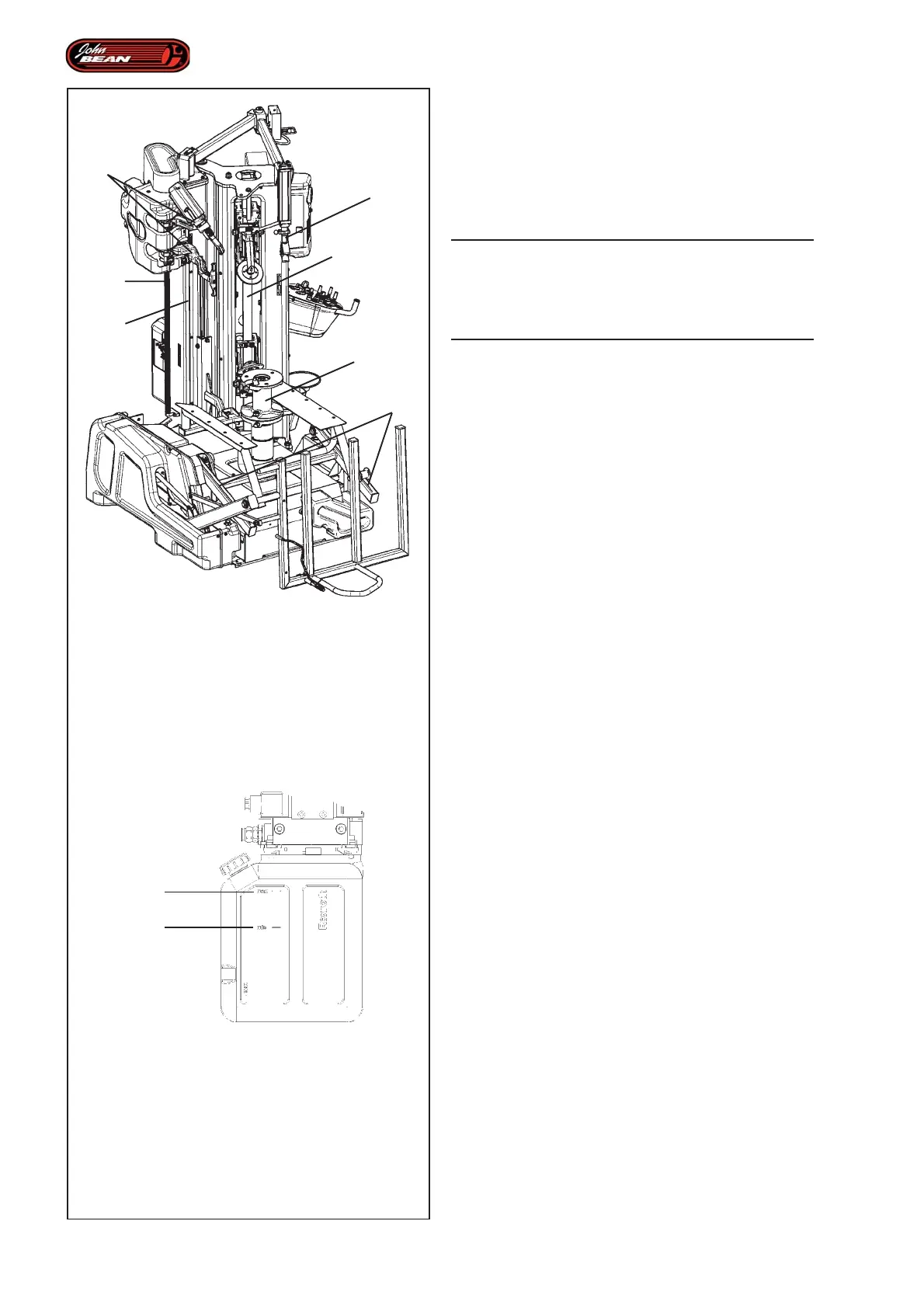

• Check hydraulic oil level (Fig.6.0-2).

Note: Perform the check with all hydraulic cylinders closed.

To achieve this condition, position the parts as indicated

below:

- Bead breaking arms; touching in the central position

- Wheel clamping bar; right down.

If necessary add:

ESSO : Nuto H 46

SHELL : Tellus oil 46

TOTAL : Azolla 46

or equivalents.

Maintain a level close to "max".

Oil change is not required.

Loading...

Loading...