111

FUEL SYSTEM

CARBURETOR SERVICE

6

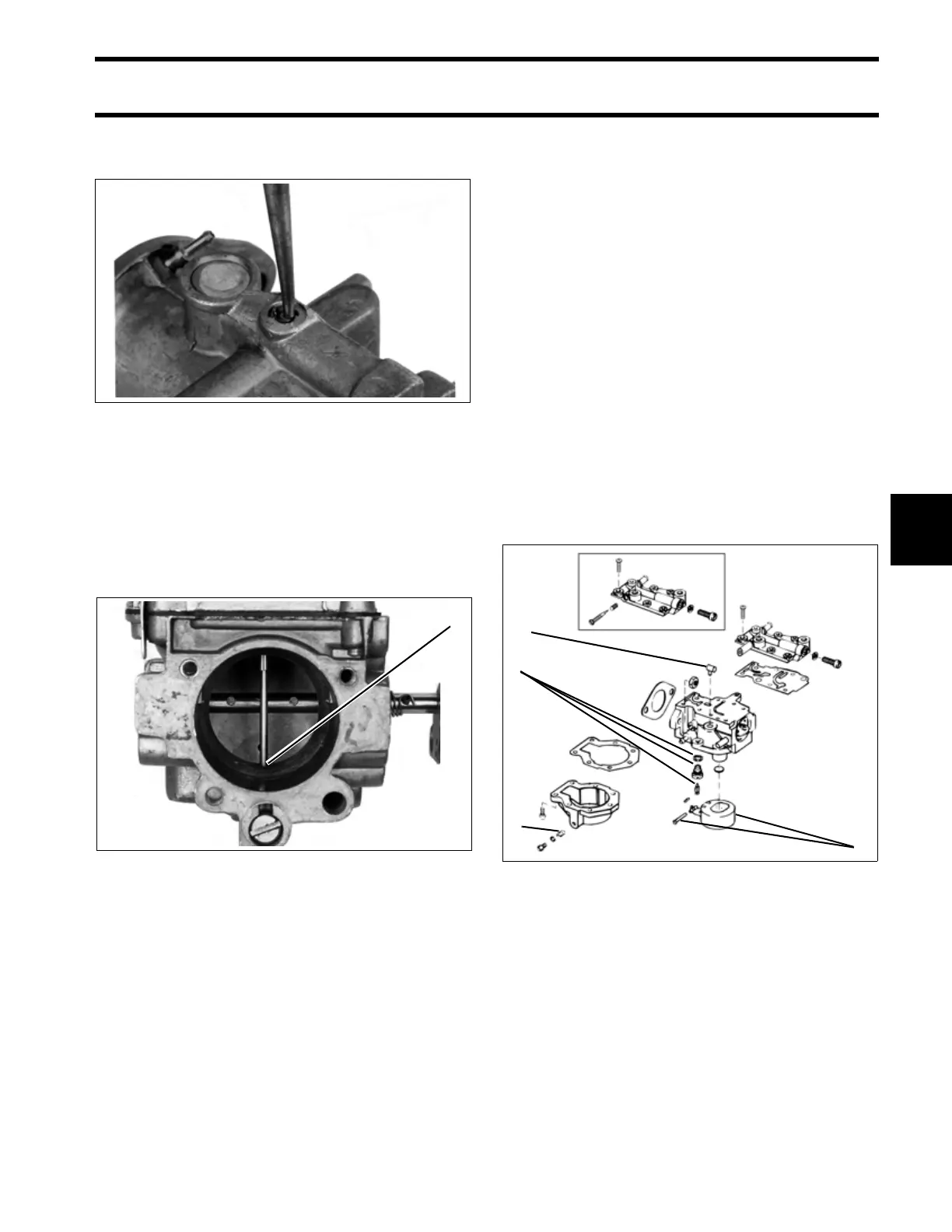

Install a new lead shot. Flatten shot with flat end

punch and plastic mallet. Check for leakage.

Check for leaks between emulsion pickup tube

and carburetor body.

• Invert carburetor body and fill idle circuit with

isopropyl alcohol.

• Check for leaks at point shown below.

• If a leak occurs, blow dry and apply a drop of

Ultra Lock at point shown.

Assembly

When installing new parts from a carburetor

rebuild kit, inspect gaskets and compare to origi-

nal gaskets to ensure all holes are correctly

punched. Also, inspect new gaskets for any loose

fibers or particles of gasket material.

IMPORTANT: Before proceeding, be sure that

all parts are perfectly clean. Be sure that all

replacement parts match original ones in size and

shape. Replace all gaskets, O-rings, and sealing

washers each time you assemble a carburetor.

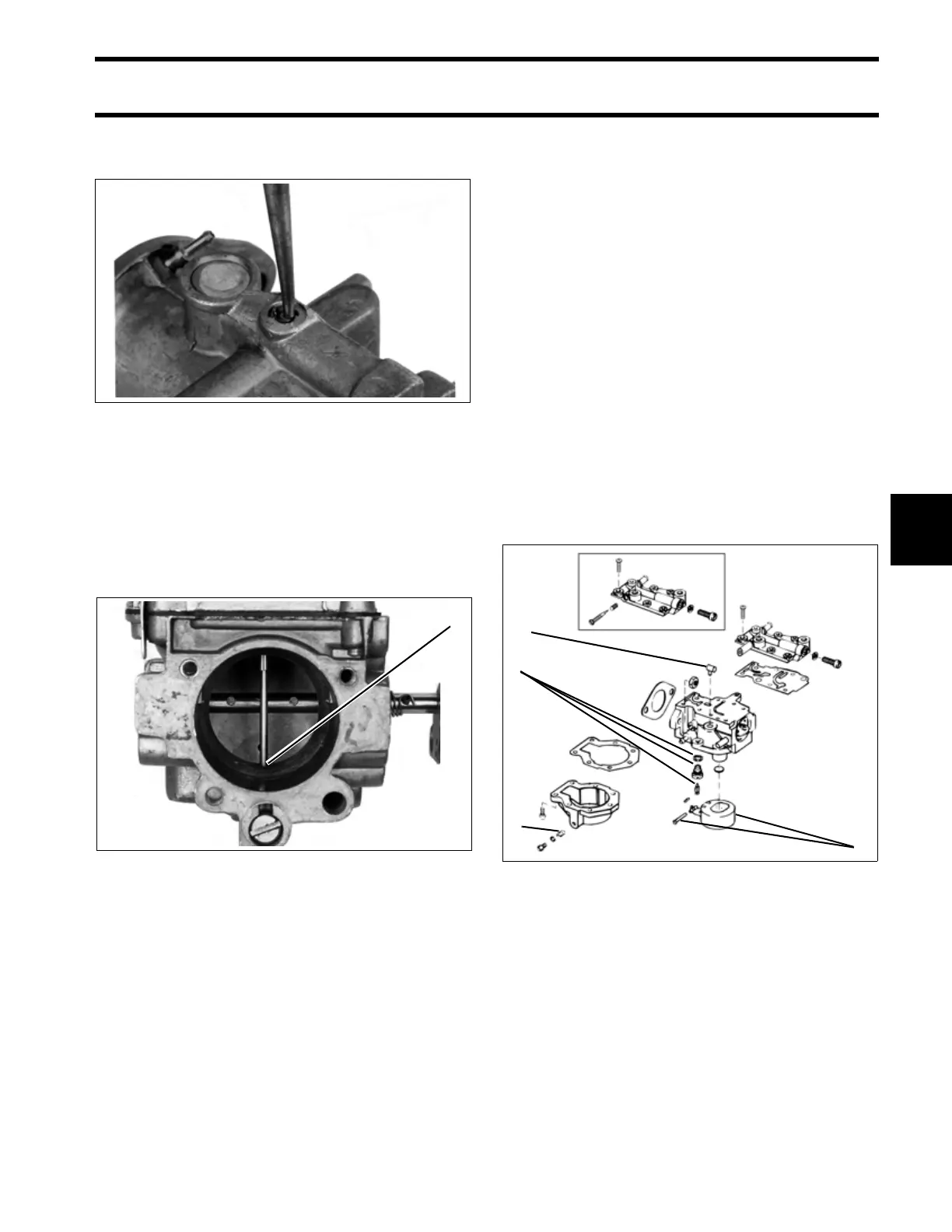

If removed, press the air vent in the carburetor

body.

Install the high-speed orifice.

Install the inlet valve assembly

Install the hinge pin and float.

Check for correct positioning of the float level. The

float level controls the height of fuel in the float

chamber and is essential to carburetor calibration

and function.

Turn carburetor body upside down and hold so

gasket surface is horizontal. The weight of the

float will close the float valve needle. Rest Float

Gauge, P/N 324891, on gasket surface and slide

16767

1. Ultra Lock application point 7626

1

1. Air vent

2. High-speed orifice

3. Inlet valve assembly

4. Hinge pin and float

002535

4

1

3

2

Loading...

Loading...