7 Configuration

64

An alarm may be caused by:

• Partial or total failure of heating elements or other parts in the control loop

• Reversal of the control direction (for example, "direct" instead of "inverse")

Functional limitations

The control loop monitoring is not active in the following cases:

• Autotuning active

• Manual mode

• Output level is not at its maximum limit (heating mode) or minimum limit (cooling mode)

Parameter dimensioning

The controller parameters must be optimally adjusted for the control loop monitoring to function correctly,

e.g. using autotuning. If alarms occur temporarily, despite the plant operating correctly, either the re-

sponse time must be increased, or the monitoring band must be narrowed. To do this, plot the ap-

proach curve, e.g. with the startup function of the setup program.

7.9.5 Output level monitoring (setup only)

Output level monitoring monitors the output level in the corrected state. The output level must be within

a definable range around a mean output level. If it is not, an alarm is issued.

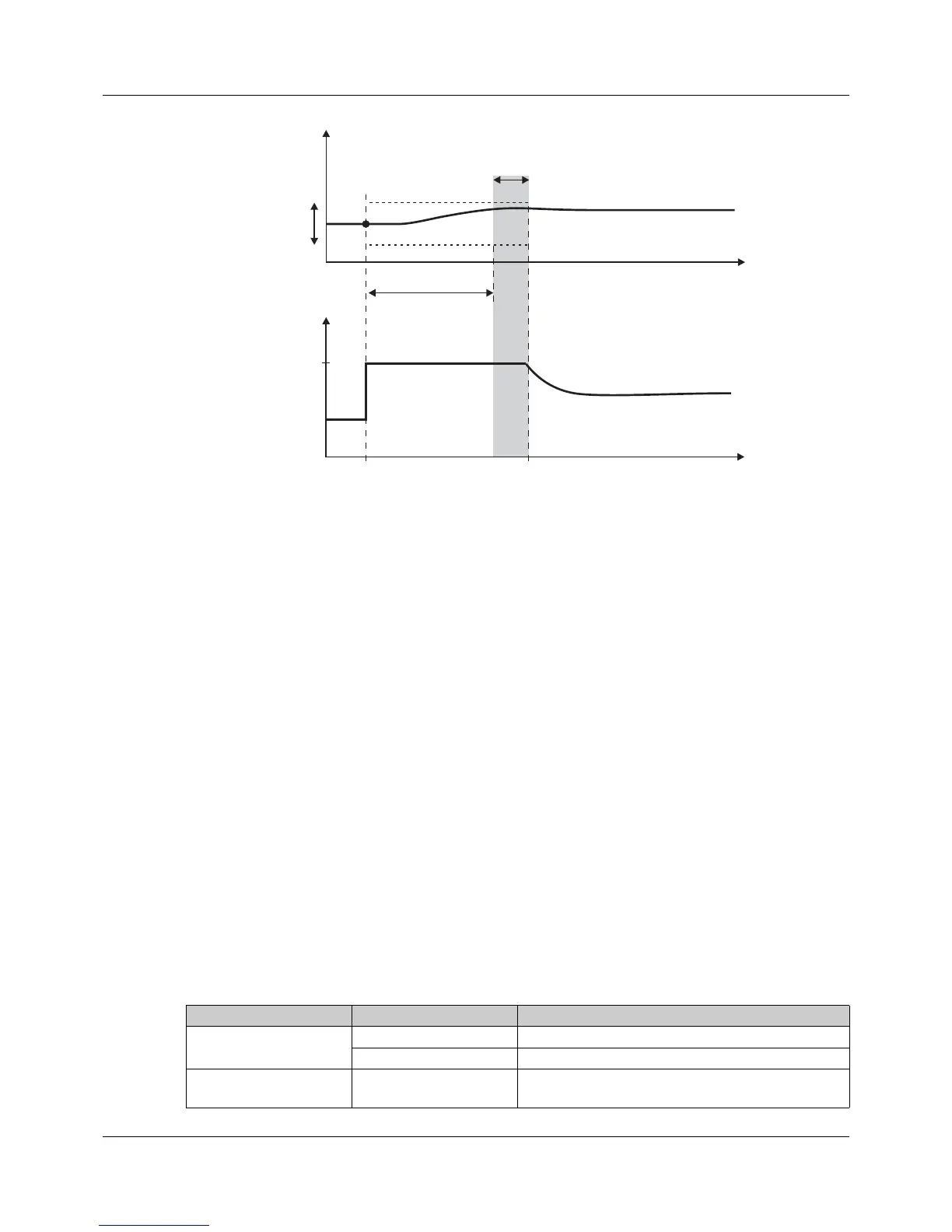

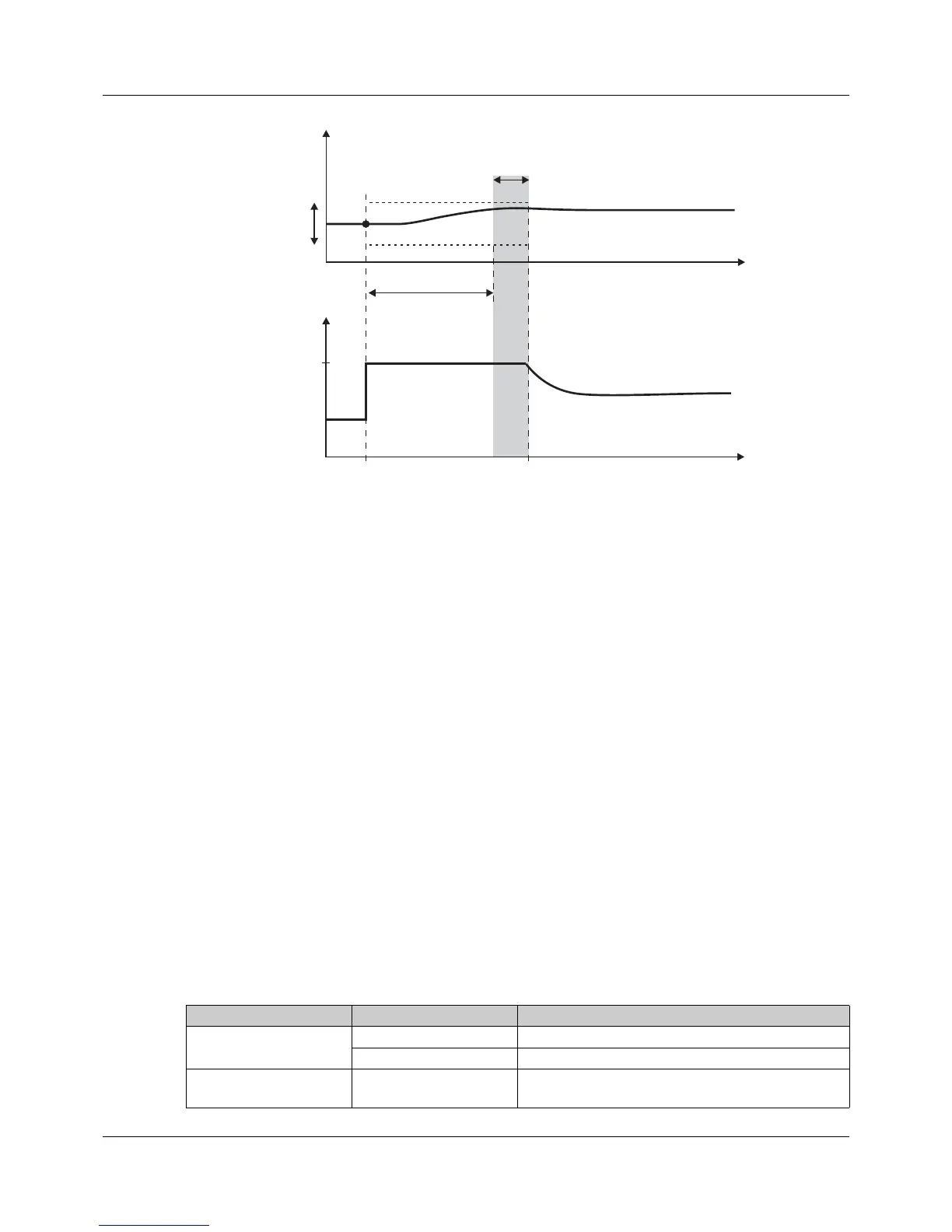

x

y

t1

T

A

Actual value

Output level

Start of monitoring

Alarm period

Δx

y

M

T

R

t2

Monitoring band

Max. output level (for example, 100 %)

Response time

End of monitoring

Parameter Selection/text/value Description

Function Off Output level monitoring is not active.

On Output level monitoring is active.

Determination time 0 to 9999 (350) Calculation time (in seconds) for the mean output

level

Loading...

Loading...