0708.GB

F 4

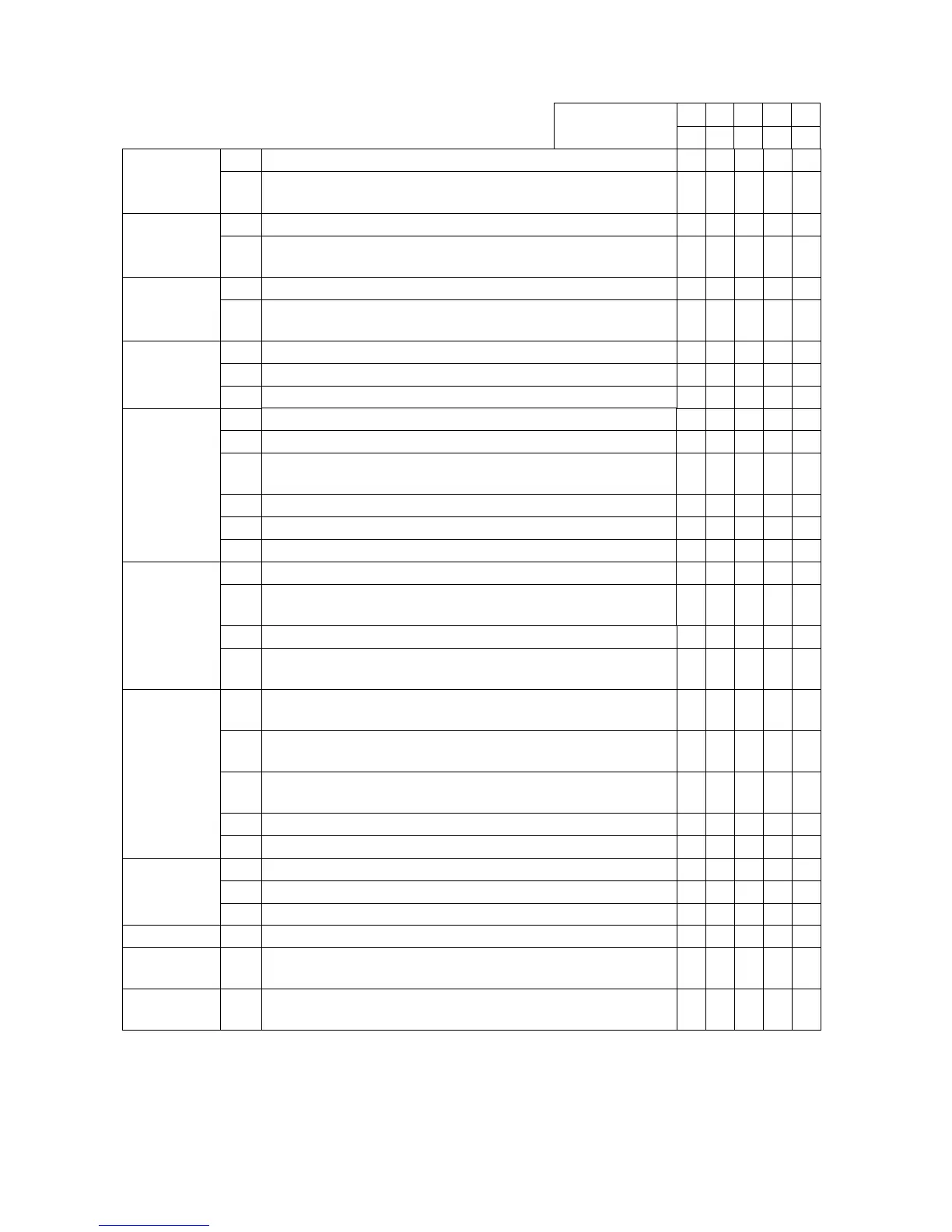

4 Maintenance checklist

Maintenance intervals

Standard = t WWMMM

Cold store

= k 123612

Chassis /

super-

structure:

1.1 Check all load bearing elements for damage ttttt

1.2 Check all bolted connections ttttt

Wheels:

3.1 Check for wear and damage ttttt

3.2 Check the wheel bearings and ensure secure fastening of

wheels

tttt

Steering: 4.1 Check play. tttt

4.2 Check steering for functionality and adjustment, lubricate if

necessary.

tttt

Brake

system:

5.1 Performance and adjustment check ttttt

5.2 Check release functionality. ttttt

5.3 Check brake pad wear. tttt

Hydraulic

system:

6.1 Performance check tttt

6.2 Check hoses and connections for leaks and damage. tttt

6.3 Check hydraulic cylinder for leaks and damage. Check hy-

draulic cylinder mountings.

tttt

6.4 Check the oil level tttt

6.5 Change hydraulic oil and filter. t

6.6 Check functionality of the pressure-limiting valves. tttt

Electrical

system:

7.1 Check that connections are properly seated. tttt

7.2 Check cable for tight seating of connections and for

damage

tttt

7.3 Check the fuses for correct amperage tttt

7.4 Check that the switches and switch cams are properly sea-

ted and work correctly.

tttt

Batteries:

9.1 Check specific gravity of acid, acid level and cell voltage*

*) Does not apply to maintenance free batteries.

ttttt

9.2 Check the terminals for secure attachment and apply

grease

ttttt

9.3 Clean battery terminal connections and check that they are

firmly seated.

ttttt

9.4 Check that the cables are in order and replace if necessary. ttttt

9.5 Check that the battery is properly secured. tttt

Hoist frame: 10.1 Check for functionality and wear, readjust if necessary. tttt

10.2 Check the condition of the rollers and connecting rods. ttttt

10.3 Check that the fork is in order. ttttt

Lubrication: 11.1 Lubricate the vehicle according to the lubrication schedule. tttt

General

checks:

12.1 Check lifting and lowering speed ttt

Technial

check:

13.1 Test the machine with nominal load. ttt

0708.GB

F 4

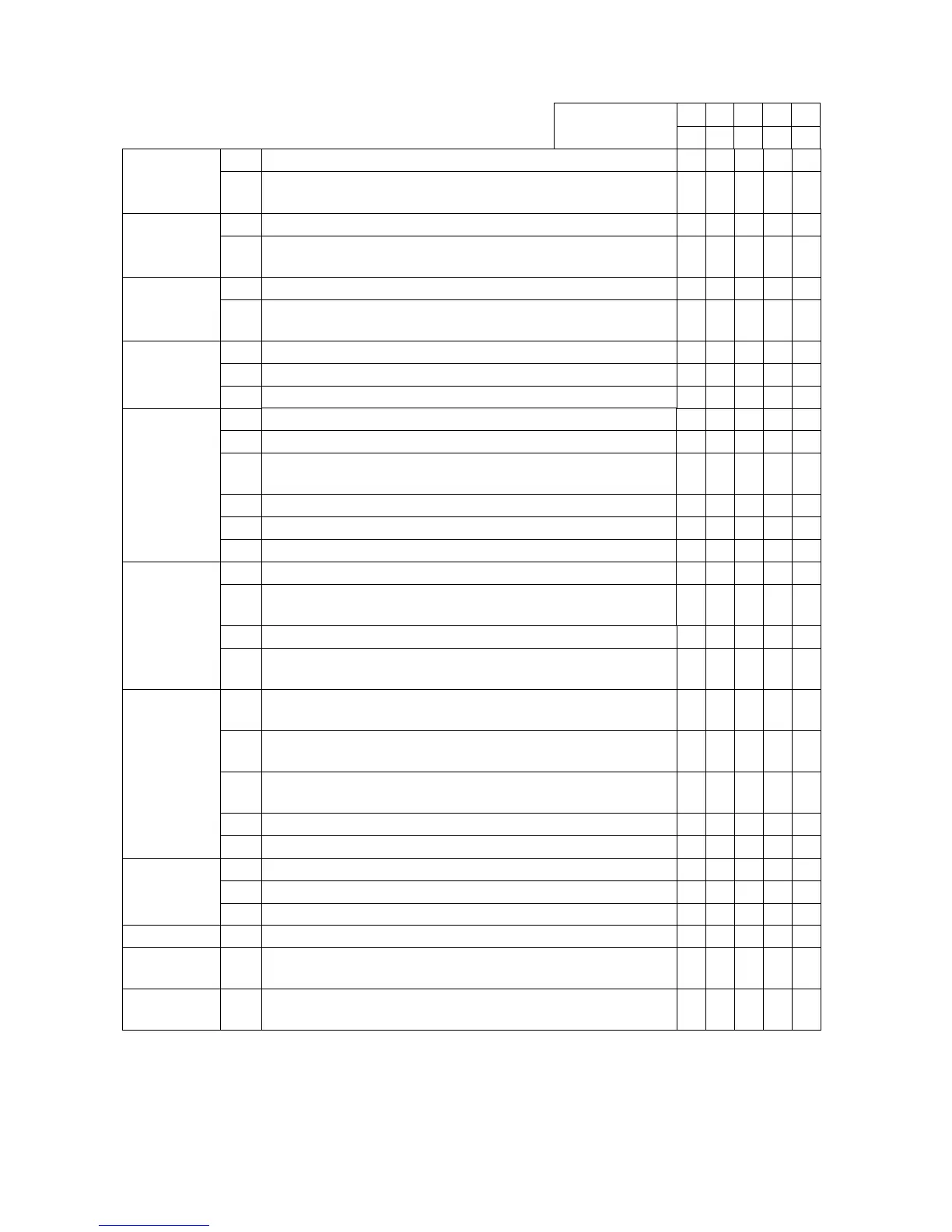

4 Maintenance checklist

Maintenance intervals

Standard = t WWMMM

Cold store

= k 123612

Chassis /

super-

structure:

1.1 Check all load bearing elements for damage ttttt

1.2 Check all bolted connections ttttt

Wheels:

3.1 Check for wear and damage ttttt

3.2 Check the wheel bearings and ensure secure fastening of

wheels

tttt

Steering: 4.1 Check play. tttt

4.2 Check steering for functionality and adjustment, lubricate if

necessary.

tttt

Brake

system:

5.1 Performance and adjustment check ttttt

5.2 Check release functionality. ttttt

5.3 Check brake pad wear. tttt

Hydraulic

system:

6.1 Performance check tttt

6.2 Check hoses and connections for leaks and damage. tttt

6.3 Check hydraulic cylinder for leaks and damage. Check hy-

draulic cylinder mountings.

tttt

6.4 Check the oil level tttt

6.5 Change hydraulic oil and filter. t

6.6 Check functionality of the pressure-limiting valves. tttt

Electrical

system:

7.1 Check that connections are properly seated. tttt

7.2 Check cable for tight seating of connections and for

damage

tttt

7.3 Check the fuses for correct amperage tttt

7.4 Check that the switches and switch cams are properly sea-

ted and work correctly.

tttt

Batteries:

9.1 Check specific gravity of acid, acid level and cell voltage*

*) Does not apply to maintenance free batteries.

ttttt

9.2 Check the terminals for secure attachment and apply

grease

ttttt

9.3 Clean battery terminal connections and check that they are

firmly seated.

ttttt

9.4 Check that the cables are in order and replace if necessary. ttttt

9.5 Check that the battery is properly secured. tttt

Hoist frame: 10.1 Check for functionality and wear, readjust if necessary. tttt

10.2 Check the condition of the rollers and connecting rods. ttttt

10.3 Check that the fork is in order. ttttt

Lubrication: 11.1 Lubricate the vehicle according to the lubrication schedule. tttt

General

checks:

12.1 Check lifting and lowering speed ttt

Technial

check:

13.1 Test the machine with nominal load. ttt

Loading...

Loading...