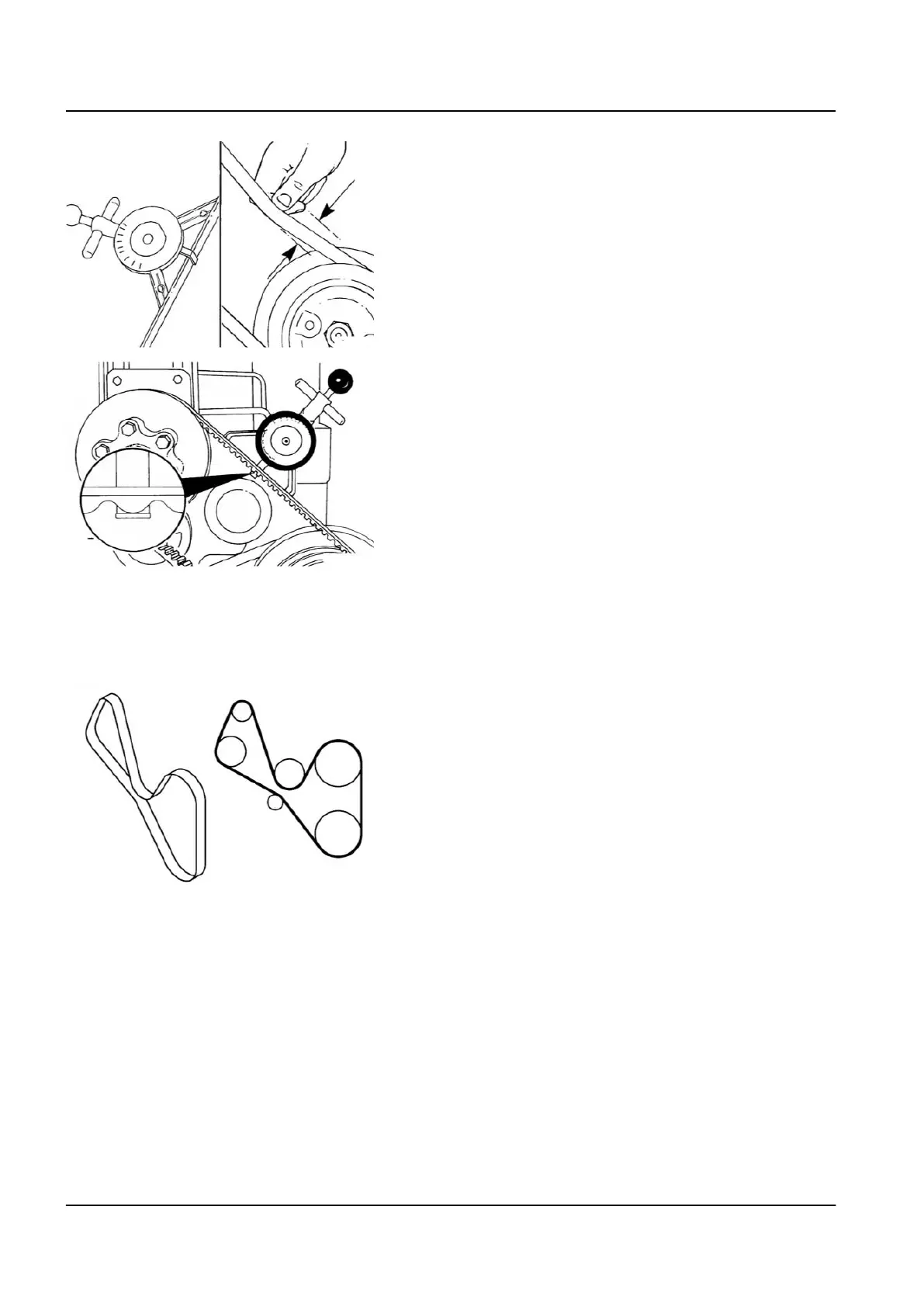

3 Measure the belt tension in the center span of the pulleys.

An alternate method (deflection method) can be used to

check belt tension by applying 110 N (25 lbf) force between

the pulleys on v-belts. If the deflection is more than one belt

thickness per foot of pulley center distance, the belt tension

must be adjusted.

4 For cogged belts, make sure that the belt tension gauge is

positioned so that the center tensioning leg is placed directly

over the high point (hump) of a cog. Other positioning will

result in incorrect measurement.

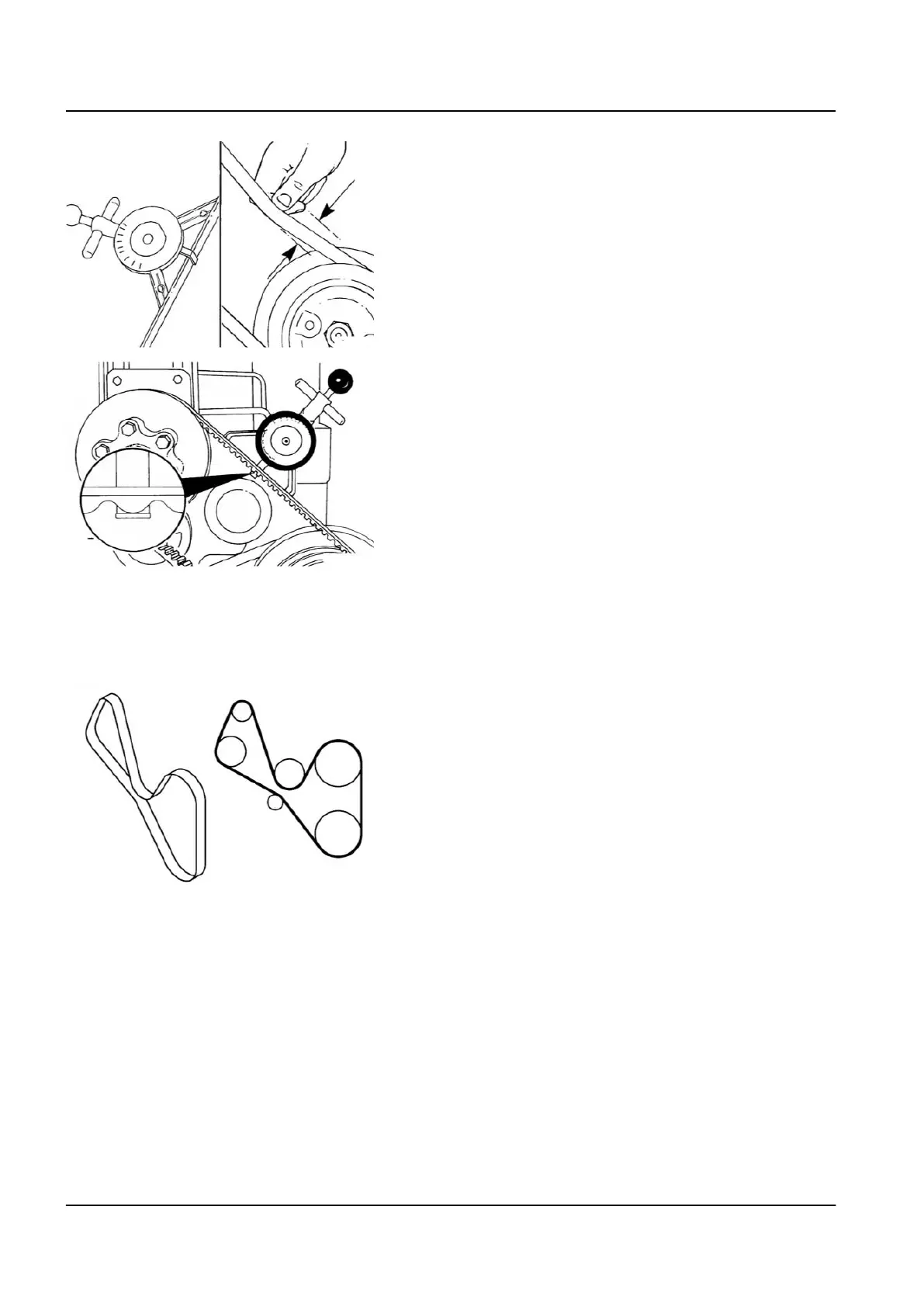

Replace the cooling fan drive belt

General

Due to the number of drive belt arrangements, this procedure does

not cover all available cooling fan drive belt routing.

To make sure the cooling fan drive belt is routed correctly upon

installation, make a diagram of the cooling fan belt routing prior to

removing the belt as shown in the illustration.

A)

Crankshaft pulley/vibration damper

B)

Fan pulley

C)

Water pump pulley

D)

Refrigerant compressor pulley

E)

.Alternator pulley

F)

Tensioner idler pulley

NOTE

Some engine driven belts are installed/supplied by the vehicle's origi‐

nal equipment manufacturer (OEM). See the OEM service manual

for removal and installation instructions.

34 1 Engine – 1.7 Cooling system

TL2 Maintenance Manual

591 003 Default

Loading...

Loading...