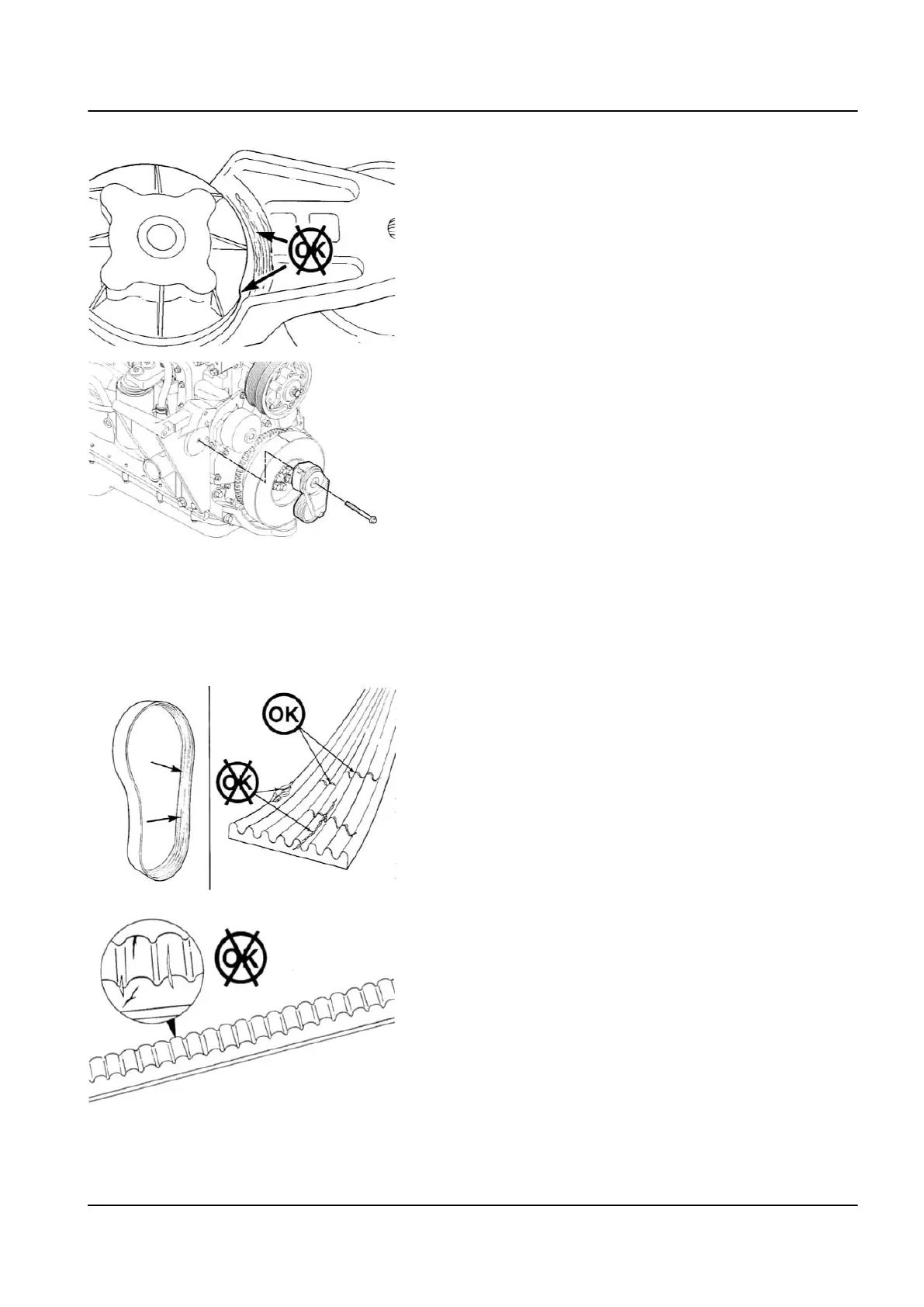

2 Examine the tensioner for a sign of the tensioner arm contact‐

ing the tensioner cap. If there is a sign of the two areas mak‐

ing contact, the pivot tube bushing has failed and the ten‐

sioner must be replaced.

3 Examine the drive belt for damage, see Chapter

1.7 Cooling

system

, paragraph

Examine the cooling fan drive belt

.

Install

1 If removed, install the belt tensioner mounting bracket and

mounting bracket capscrews (tightening torque 24 Nm).

NOTE

Some belt tensioner mounting brackets use internal fasteners for

clearance.

2 Install the belt tensioner and capscrew (tightening torque 43

Nm).

3 Install the drive belt, see Chapter

1.7 Cooling system

, para‐

graph

Replace the cooling fan drive belt

.

4 Connect the battery cables. Refer to the OEM service manual.

5 Operate the engine and check for leaks.

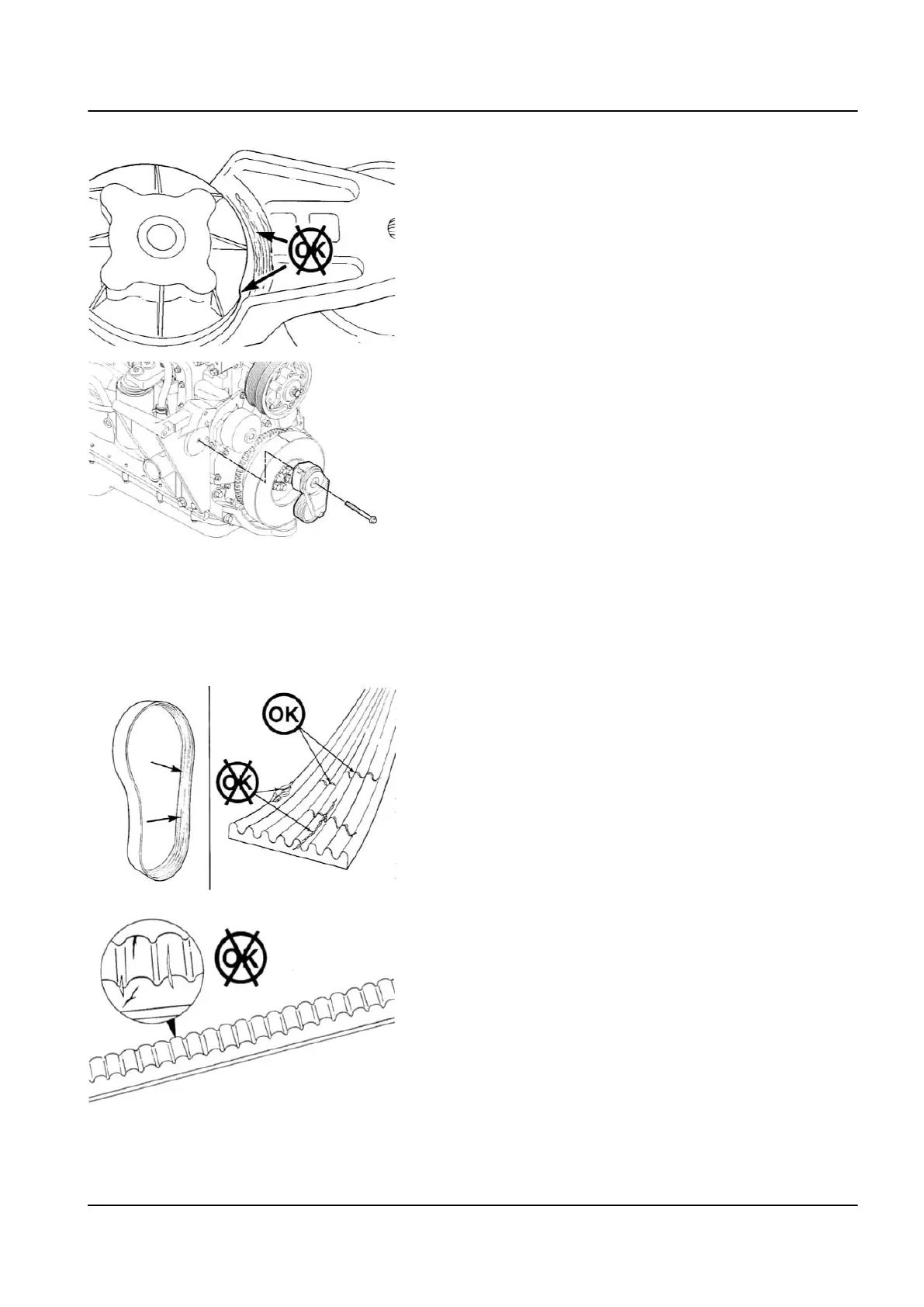

Examine the cooling fan drive belt

1 Inspect the drive belt for damage.

Transverse (across the belt) cracks are acceptable.

Longitudinal (direction of belt ribs) cracks that intersect with

transverse cracks are not acceptable.

2 If the belt is frayed, punctured, or material is missing, the belt

is unacceptable for reuse and must be replaced.

Belt damage can be caused by:

•

Incorrect tension

•

Incorrect size or length

•

Pulley misalignment

•

Incorrect installation

•

Severe operating environment

•

Oil or grease on the side of the belts.

1 Engine – 1.7 Cooling system 33

TL2 Maintenance Manual

591 003 Default

Loading...

Loading...